16

ADJUSTMENTS

CHANGING THE BANDSAW BLADE

Unplug the machine from the

electrical supply. This ensures that the Bandsaw

will not accidentally turn on if the ON/OFF switch is

bumped.

1. Open the top and bottom wheel doors.

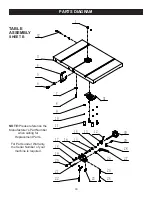

2. Release the blade tension by moving the Quick

Release Lever (#17C) from right to left. Fig. 20.

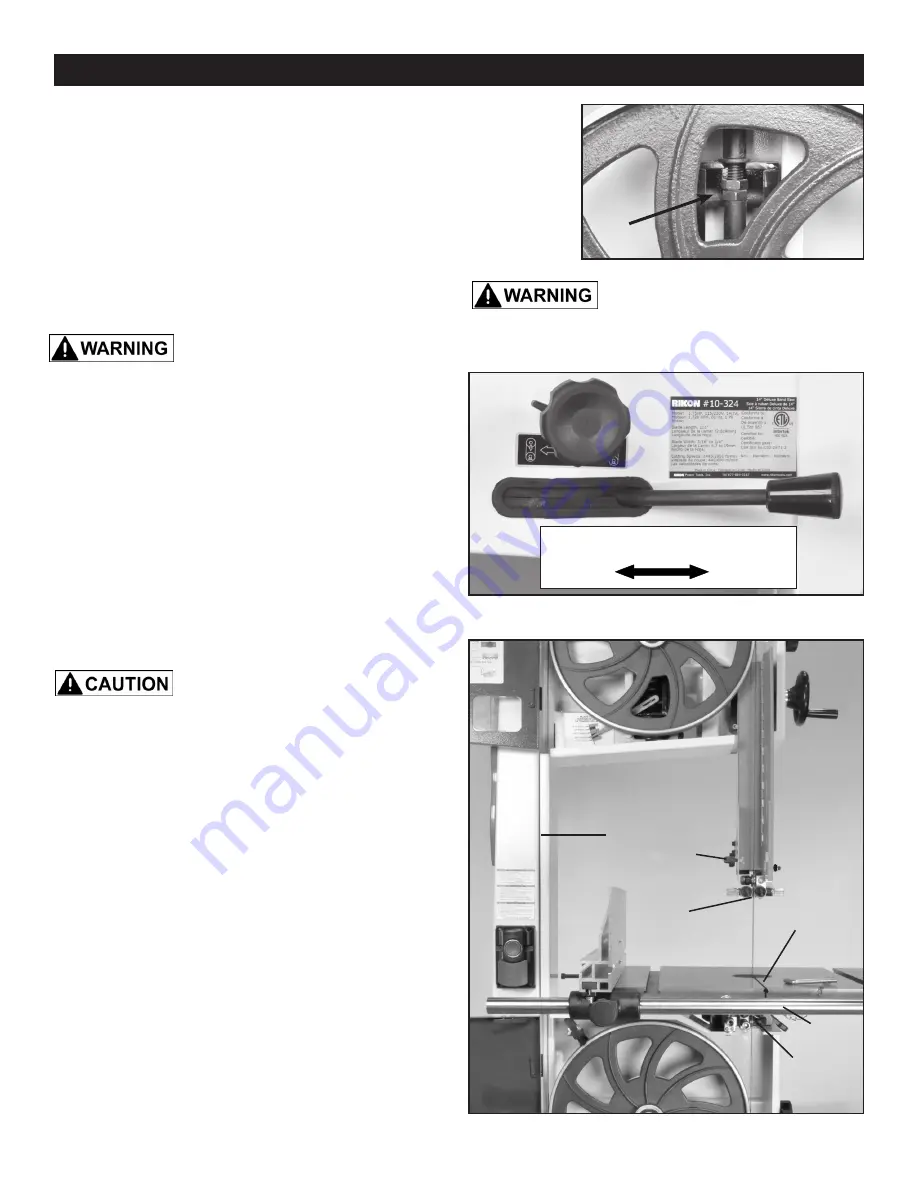

3. Open the Hinged Door (#11D) on the blade guard

by loosening the Locking Handle (#14D). Fig. 21, A.

4. Remove the saw blade from the top wheel then

feed it through the upper blade guides (B), slot in the

table (C), lower blade guides & lower blade guard (D),

out of the slot in the column of the machine (E), off of

the bottom wheel, and then around the front rail (F).

Be careful not to cut yourself on

the sharp saw teeth. Wear gloves for protection.

5. When installing the new blade, reverse the steps

1-4 above. Ensure that the blade teeth are pointing

downwards and towards you at the position where the

blade passes through the table.

6. Center the blade on both wheels.

7. Re-tension the new blade by moving the quick

release lever back to the ON position, Fig. 20, and

check the

blade tracking. The blade should run in

the center of the wheels. Refer to “Tracking the Saw

Blade” on page 14 for more details.

8. Reset the blade guides as described in the section

“Adjusting the Blade Guides” on pages 17 and 18.

9. Reset the blade tension as described in the section

“Adjusting the Blade Tension” on page 15.

10. Close the hinged door on the blade guard and

tighten the locking handle to keep the door closed.

11. Close and lock both the wheel doors before

reconnecting the power supply.

FIGURE 20

Quick Release Lever

ON

OFF

FIGURE 21

THE MACHINE MUST NOT BE

PLUGGED IN AND THE POWER SWITCH MUST BE IN THE

OFF POSITION UNTIL ALL ADJUSTMENTS ARE COMPLETE.

A

B

C

D

E

F

ADJUSTING THE BLADE TENSION STOP

If you can not set full tension on a new blade, the blade is most likely

welded a bit longer than the standard 111” length, and so just beyond

the pre-set tensioning range of the saw. To fix this, behind the top

bandsaw wheel is the threaded Blade Tension Rod (#2C). Loosen the

Nuts (#3C) and screw them upward about 1/4”, then retighten. This will

increase the blade tensioning range of the saw for your new blade.

Summary of Contents for 10-324TG

Page 43: ...43 OPERATION...