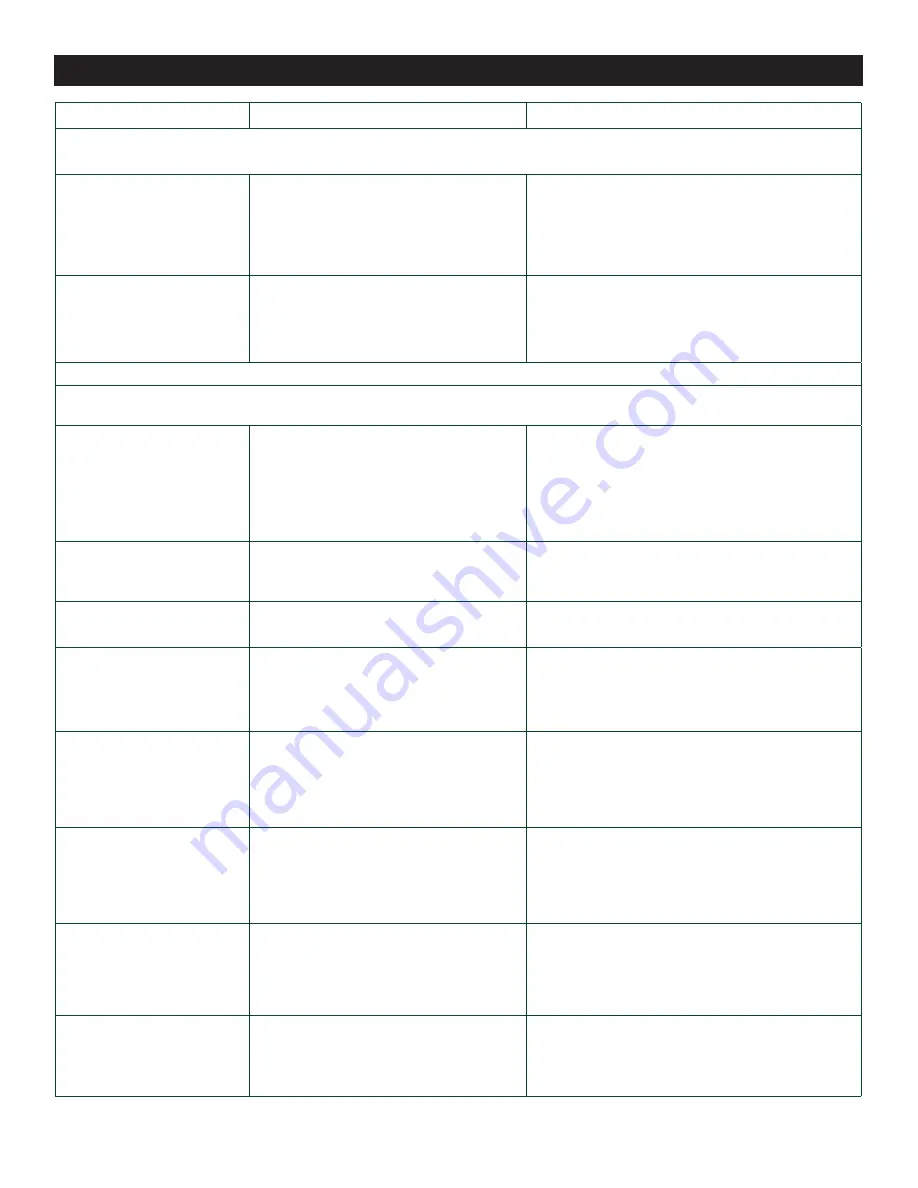

SYMPTOM

POSSIBLE CAUSES

SOLUTIONS

TROUBLESHOOTING THE JOINTER - continued

Milled surface grain is

rough, raised or fuzzy

1. Lumber has a high moisture

content

2. Knives are dull

1. Reduce the moisture content by drying

it, or switch to other properly seasoned

lumber.

2. Replace the knives for new sharp edges.

Milled surface is glossy

1. Cutting depth is too shallow

2. Knives are dull

3. Feed rate is too slow

1. Increase depth of cut slightly.

2. Replace the knives for new sharp edges.

3. Increase feed rate.

TROUBLESHOOTING THE PLANER

Poor feeding of lumber

through the planer

1. Drive belt is worn or broken

2. Drive belt tension spring is broken

3. Lumber sticking on planer's table

4. Feed rollers not applying enough

pressure on lumber

1. Check and replace as necessary.

2. Check tension and/or replace the spring.

3. Clean the table and apply silicone based

lubricant to reduce friction.

4. Adjust the feed roller pressure.

Not planing lumber to a

uniform thickness

1. Planer table is not level to the

cutterhead

1. Adjust table and/or cutterhead as needed.

Board thickness does not

match scale markings

1. Depth of cut scale not set correct

1. Adjust scale to match board thickness

Small raised lines are run-

ning along the surface

1. Knives are nicked or broken

1. Shift knives left & right so nick is not in the

same location on all 3 rotating knives.

2. Replace the broken knives.

1. Feed rollers not set properly

2. Lumber not supported when fed

into or exiting the planer

3. Short boards not butted

1. Adjust feed roller height for applying pres-

sure onto lumber to keep flat on table.

2. Support long boards with roller stands.

3. Run boards butt end to end through planer

Planed surface is torn -

also called 'chip out' or

'tear out'

1. Cutting against the grain

2. Cut is too deep

3. Knives are dull

1. Cut with the grain. For figured woods, take

shallow cuts to minimize tear out.

2. Reduce cutting depth to 1/16" or less.

3. Replace the knives for new sharp edges.

Planed surface grain is

rough, raised or fuzzy

1. Lumber has a high moisture

content

2. Knives are dull

1. Reduce the moisture content by drying

it, or switch to other properly seasoned

lumber.

2. Replace the knives for new sharp edges.

Planed surface is glossy

1. Cutting depth is too shallow

2. Knives are dull

3. Feed rate is too slow

1. Increase depth of cut slightly.

2. Replace the knives for new sharp edges.

3. Increase feed rate.

For parts or technical questions contact: techsupport@rikontools.com or 877-884-5167.

TROUBLESHOOTING

23

Summary of Contents for 25-010

Page 31: ...31 WARRANTY...