14

ADJUSTMENTS

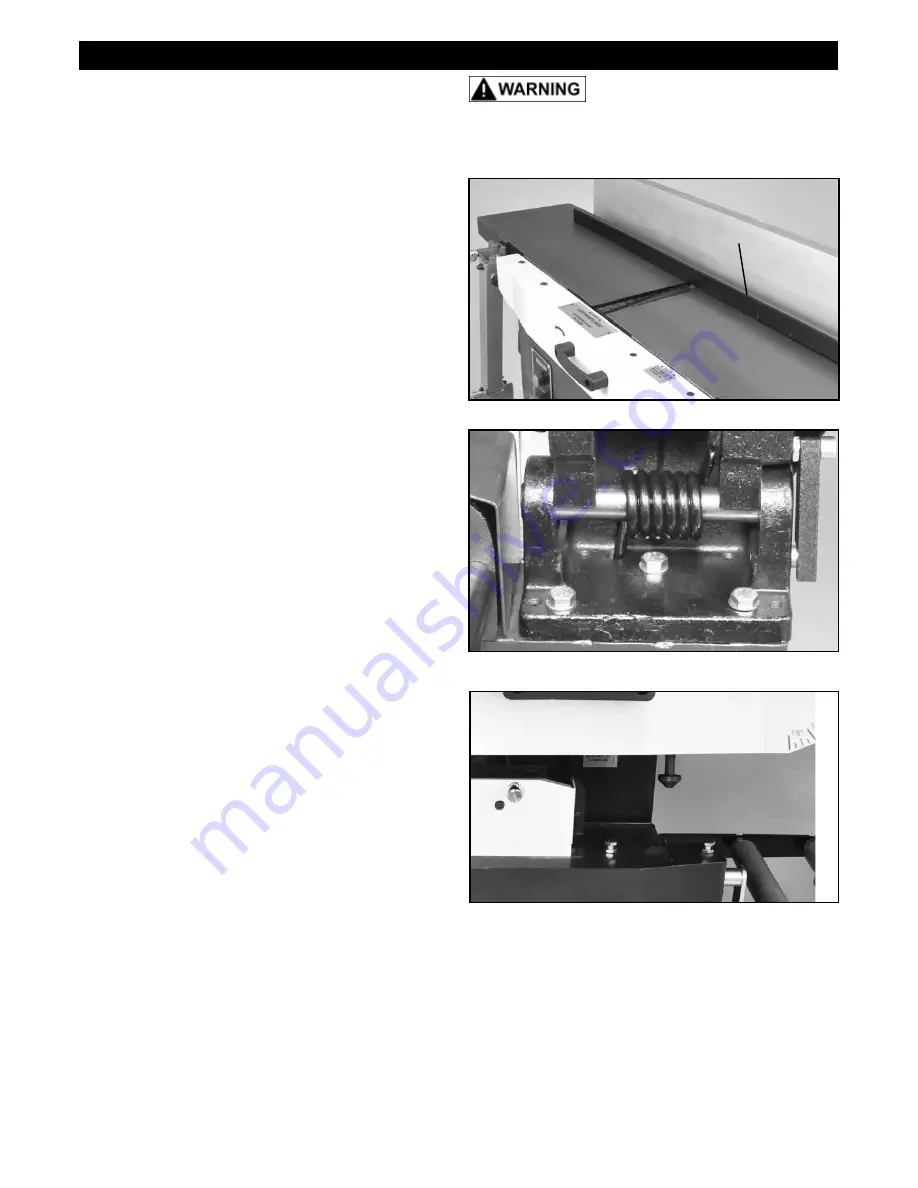

FIG. 21

ADJUSTING THE INFEED TABLE

The Infeed Table is pre-set by the factory to align with

the cutterhead's knife inserts. Should an adjustment be

required, the following steps are needed.

1. Raise the infeed table to its highest, 0", level and use

a metal straight edge to check its level flatness with the

outfeed table. FIG. 21.

2. The jointer table, with the fence and cutterhead guard,

needs to be lifted up and back into a vertical position. See

page 21, steps 1 & 2, for full details on this process. The

Dust Chute (#66) should be left in the down, jointer-use

position so adjustments can be made.

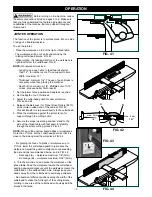

3. With the table up, the Support Base (#120) for the

infeed table is exposed. The base has three Hex Bolts

(#132) and four Set Screws (#134) that fasten the table to

the cabinet. The set screws can be adjusted to slightly tilt

the table to align it with the infeed table. FIG. 22.

3. Slightly loosen the three hex bolts so that the set

screws can be adjusted. With small 1/8 or 1/4 turns of the

set screws, tilt the table as needed. A clockwise turn will

advance the set screw, a counter-clockwise turn will retract

them from the base casting.

- The pair of 2 set screws to the far left will raise the left

end of the table. FIG. 22, A & B.

- The pair of 2 set screws to the far right will raise the

forward edge of the table, nearest the cutterhead. C & D.

- The pair of screws furthest back in the base will tilt the

back of the table upward. B & C.

- The pair of 2 set screws at the front of the base will

lift up the front edge of the table. A & D.

- The table can also be tilted down, or up, towards a

specific corner should the situation arise. Three of the set

screws would be adjusted for this. Example: To tilt the far

left corner of the table up, set screws D, then A & C would

be turned. Screw B would be the 'pivot point'

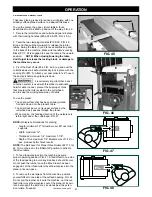

4. The table can also be tilted forward or back with the two

Special Bolts (#18, FIG. 23, E & F). The combination of the

six bolts and screws (A-F) provide a great range of table

positioning to level it with the infeed table.

5. Once adjustments are made, the infeed table should be

checked for flatness with the outfeed table with a straight

edge. FIG. 21. This may require a few attempts to get the

tables in alignment. When the infeed table is flat to the

outfeed table, the hex bolts can be tightened to lock the

settings.

6. With the table lowered, make sure the two safety Table

Locks (#104, G) will engage. These special bolts can be

adjusted up or down by their threaded ends, then secured

with their attached Nuts (#106). FIG. 23.

7. Re-adjust, or install the fence and guard, then the

machine is ready for use.

THE MACHINE MUST NOT BE

PLUGGED IN AND THE POWER SWITCH MUST BE IN

THE OFF POSITION UNTIL ALL ADJUSTMENTS ARE

COMPLETE.

FIG. 22

PLANER TABLE ALIGNMENT

The machine has been factory set before shipping - the

planer's table being set parallel to the cutterhead knives.

But once the machine has been set in its final location in

the shop, the table alignment should be checked to make

sure that there has been no movement during its handling.

WARNING:

When working on, or near the machine's bed,

avoid the risk of personal injury by cuts that may result

from touching the knife inserts' sharp edges!

Continued on page 15

FIG. 23

A

B

C

D

E

F

G

STRAIGHT

EDGE