16

ADJUSTMENTS

THE MACHINE MUST NOT BE

PLUGGED IN AND THE POWER SWITCH MUST BE IN

THE OFF POSITION UNTIL ALL ADJUSTMENTS ARE

COMPLETE.

ADJUSTING THE CUTTERHEAD

The Cutterhead that holds the knife inserts is fastened to

the machine's cabinet, and is not adjustable. Based on

the position of this main component of the machine, all of

the other parts - rollers and tables - are then pre-set by

the factory to align with the cutterhead. Should any of the

tables or rollers get out of parallel with the cutterhead, they

can be adjusted separately following the instructions in this

manual.

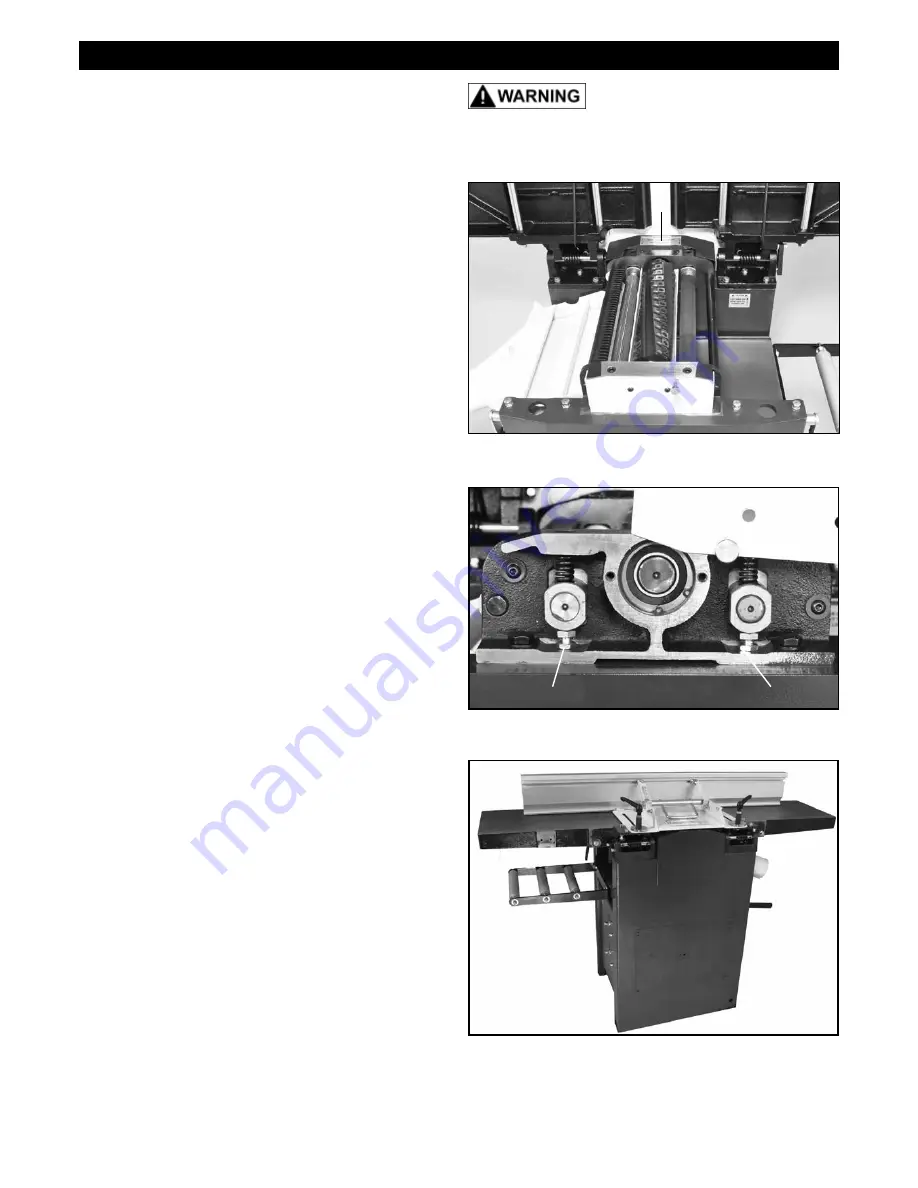

ADJUSTING THE FEED ROLLERS

The Infeed (#78) and Outfeed (#61) Rollers are pre-set by

the factory to align parallel with the cutterhead and knife

inserts. These spring loaded rollers are set just below the

cutterhead, so that they engage the lumber and move it

through the planer. Should an adjustment be required to

increase or decrease the amount of downward pressure

they exert on the lumber, the following steps are needed.

1. Make sure that the planer/jointer's switch is turned off,

and the plug is disconnected from the power source.

2. The jointer table, with the fence and cutterhead guard,

needs to be lifted up and back into a vertical position. See

page 21, steps 1 & 2, for full details on this process.

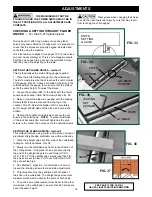

3. With the jointer table up, the Front Guard (#53, A) and

Rear Guard (#91, B) must be removed to access the bolts

that will adjust the feed rollers' pressure. FIG. 27.

NOTE:

The Front Guard with the 2 screws (#52) removed,

can be rotated out of the way, leaving the dust collector's

spring-loaded Locating Pin (#51, P) in place. FIG. 28.

The Rear Guard can be removed once the 2 locating

screws are removed, by lowering the jointer table then

removing the fence assembly.

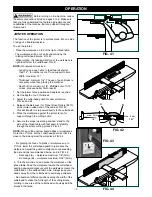

4. Under the Cutterblock Brackets (#57 & 69), the Tight-

ening Screws (#73) hold the compression Springs (#72) in

place on the brass Shaft Sleeves (#59). The bottom Hex

Bolts (#67, FIG. 28, N) can be tightened or loosened with a

wrench to adjust the feed rollers. FIG. 28.

- By raising the hex bolts UP, the spring is compressed

and the downward pressure of its roller is increased upon

the lumber being fed through the planer.

- By lowering the hex bolts DOWN, the spring compres-

sion is reduced, and its rollers exert less pressure down

onto the lumber.

5. Once the rollers are set, secure the Bolts (#67) in place

with the Nuts (#64), re-install the guards, lower the jointer

table with fence & guard, and the machine is ready for use.

FIG. 27

FIG. 28

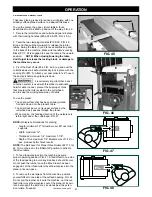

ADJUSTING DRIVE BELTS

The cutterhead drive belt and the feed gear drive belt need

to be checked periodically and re-tightened if necessary.

Belts will stretch with use, especially when they are new

FIG. 29

Continued on page 17

A

B

N

N

A

B

and are breaking in. Both drive belts are located behind the

machine's rear cover and side panel. FIG. 29, A & B.

P