Maintenance

To avoid injury due to unexpected starting, before cleaning or carring out maintenance

work, switch off and disconnect the drill press from the power source.

1. Never use water or other liquids to clean the drill press. Use a dry brush.

2. Regular maintenance of the drill press will prevent unnecessary problems.

3. Keep the table clean to ensure accurate cutting.

4. Keep the outside of the machine clean to ensure accurate operation of all moving parts and

prevent excessive wear.

5. Frequently blow out any dust that may accumulate on the motor.

6. Apply paste wax to the table and column, to help keep the surface clean.

7. Check belts for wear and replace.

WARNING:

LUBRICATION

All of the ball bearings are packed with grease at the factory. They require no further lubrication.

Periodically lubricate the worm gear (part# 18C) in the table elevation mechanism, the rack bar

(part# 2C), and the spline (grooves) in the spindle (part#15A). This will keep the operation of the drill

press smooth.

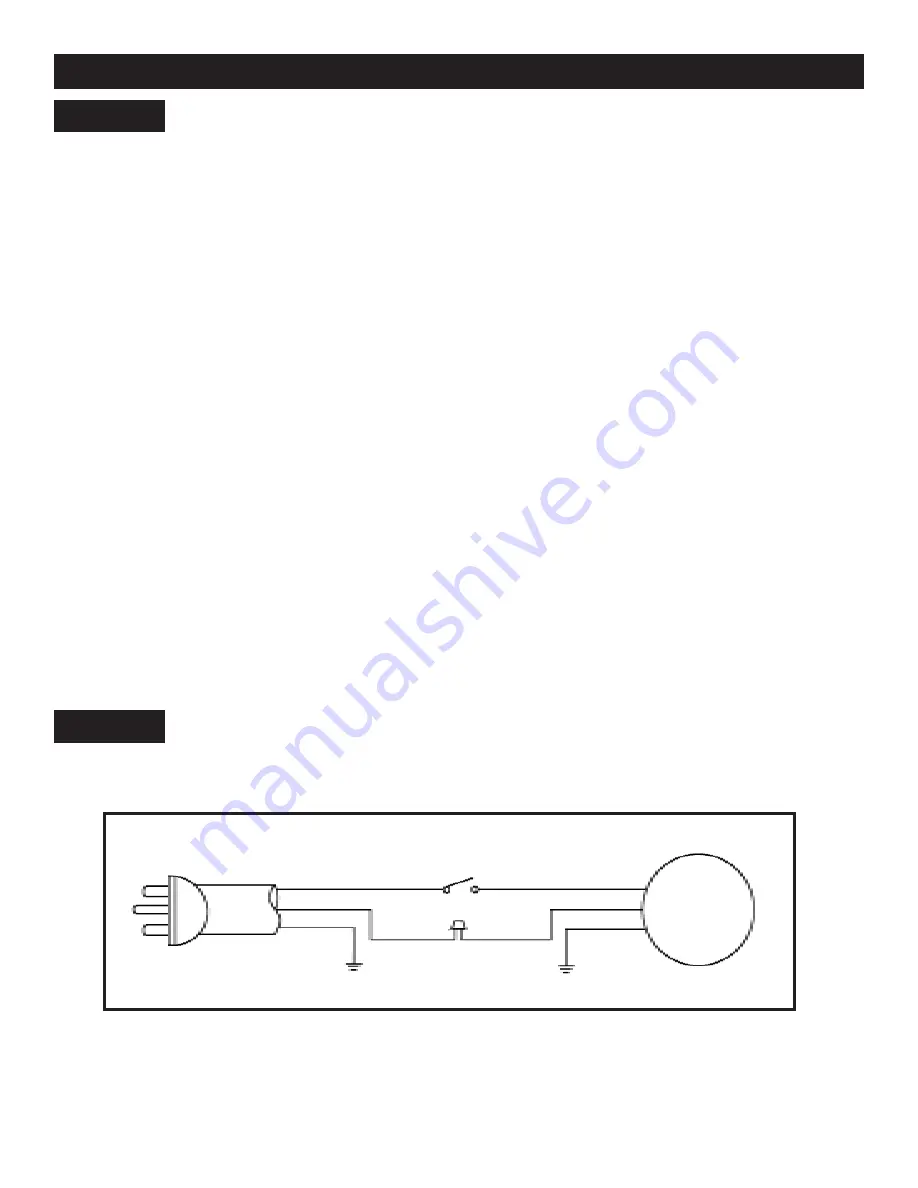

WIRING DIAGRAM

This machine must be grounded. To avoid electrocution or fire, any

repairs to electrical system should be done only by a qualified electrician, using genuine replacement

WARNING:

Motor

Switch

110V Plug

14