B

A

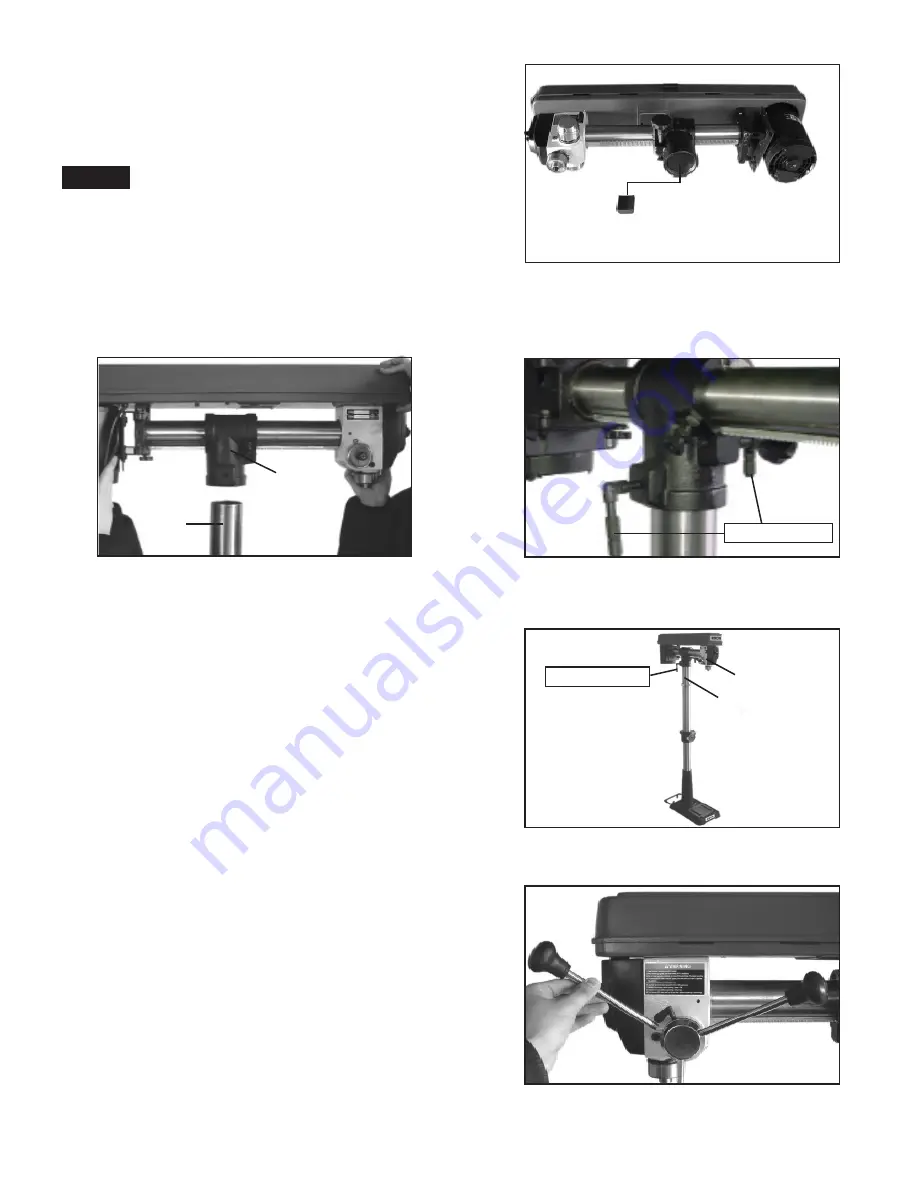

Figure 7

Head Assembly

1. Place the locking shoe (part# 15B) in the

recessed

pocket of the head. (Fig. 5)

2. Place the drill press head (A-Fig. 6) onto the

column (B-Fig. 6) as far as it will go.

3. Attach the 2 clamping levers (part# 30B) on the

drill press column guide (part# 18B). (Fig. 7)

Figure 5

Figure 6

Figure 8

Figure 9

8

Assistance is needed for this next

step.

clamping levers

A

B

locking lever

4. Align the drill press head (A-Fig. 8) with the

base of the drill press.

5. Tighten the drill press head (A-Fig. 8) to the

column (B-Fig. 8) by tightening the locking lever

(part# 30B) on the left side of the guide column

(part# 18B).

6. Attach the three feed handles (part# 35B) to

the hub (part# 36B). Fig. 9