11

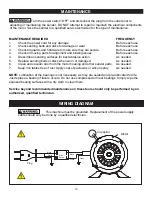

FIG. 10

FIG. 11

ASSEMBLY

FIG. 12

INSTALL THE DISC SANDING TABLE

21. An adjustable Handle and Washer (#25, 26)

are supplied to hold the Sanding Disc Table (#22)

in position on the sanding base.

22. Line the disc sanding table’s slotted right end

with the curved keyway in the sanding disc base.

Position it in the keyway so that the handle can

be installed, fastening the parts together. FIG. 10.

NOTE:

It is easier to thread the bolt part of

the handle on first, then attach the handle to it

using the spring loaded Allen head cap screw

provided.

23. Attach the Angle Scale Pointer (#16) to the

sanding disc frame with the M4 Phillips pan head

Screw (#14). The pre-drilled hole is located just

below the angle gauge. See FIG. 11.

Adjust the pointer after the table is set to 90°, see

page 16. The disc table will tilt from 45° to 90°.

FIG. 12.

INSTALL THE BELT SANDING TABLE

24. An adjustable Handle and Washer (#25, 26)

are supplied to hold the Sanding Belt Table (#79)

in position on the Sanding Frame (#64).

25. Position the sanding belt table around the

belt, and so that it’s lower bracket with the curved

slot is in position with the threaded hole in the

frame.

26. Fasten the table in place. Thread the bolt

portion of the locking adjustable handle through

the bracket’s slot and into the threaded hole of

the sanding frame. FIG. 13.

The table will tilt from 45° to 90°. FIG. 14.

NOTE:

See pages 13 and 14 for additional infor

-

mation on adjusting the sanding tables.

Tables should be adjusted to a

distance of about 1/16” away from the sanding

disc or belt to prevent accidents if work or your

fingers get stuck in the gap while the sander is

running.

FIG. 13

FIG. 14

CURVED KEYWAY

ANGLE SCALE &

POINTER