12

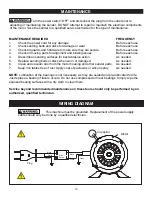

FIG. 15

ASSEMBLY

California Proposition 65 Warning

WARNING:

Some dust created by power sanding, sawing, grinding, drilling, and other construction

activities contains chemicals known to the State of California to cause cancer and birth defects or

other reproductive harm. Your risk from exposure to these chemicals varies, depending on how often

you do this type of work. To reduce your exposure, work in a well-ventilated area and with approved

safety equipment, such as dust masks that are specially designed to filter out microscopic particles.

For more detailed information about California Proposition 65 log onto rikontools.com.

Lag Bolt

Machine Bolt

Washer

Rubber Foot

Washer

Lock Washer

Nut

Pilot Hole for

Lag Bolt

Workbench

MOUNTING THE SANDER

TO A WORKBENCH OR STAND

CAUTION:

If during operation there is any

tendency for the sander to tip over, slide or walk

on the supporting surface, the sander should be

properly mounted to a workbench or stand.

1. Rubber feet are fastened to this sander prior

to shipping. They may, or may not, be used when

attaching the sander to a bench or stand.

2. Position the sander on the workbench.

3. There are two options for mounting the sander

to the workbench:

- Use the two extra holes in the base (located by

the front right foot, and rear left foot when looking

at the sanding belt table);

- Use the four holes that are securing the

rubber feet. The bolts will have to be removed

and replaced with other fasteners to go through

the sander’s base and feet. See Figure 15 for

illustrations of each method.

4. Mark the workbench through the selected

mounting holes located in the sander’s base, per

above.

5. Drill holes in the workbench at the marks.

6. Using long bolts, washers, lock-washers and

nuts; or lag bolts; (fasteners not supplied), secure

the sander to the workbench. FIG. 15.

TEST RUNNING THE SANDER

With the sander fully assembled and checked to

make sure that all parts and fasteners are se

-

cure, test run the sander to confirm that it runs

smoothly. If any adjustments are needed, these

must be done with the machine turned off and

unplugged for safety.

If you have any questions regarding assembly

before operating the sander, contact RIKON Tech

Support at 877-884-5167 for assistance.

INSTALL THE TOOL HOLDERS

Holders (#88, 90) for convenient storage of the

Miter Gauge and Wrenches are supplied. Mount

them onto the back of the Belt Frame Casting

(#64) with the Phillips Screws supplied (#89).

WRENCH HOLDER

MITER GAUGE HOLDER