13

DISC SANDING

1. Depending on what type of sanding that you

will be doing, set the Sanding Disc Table to the

proper angle from 45° to 90°.

2. Once the table has been set for the correct

sanding angle, and all fasteners are secure, the

machine can be plugged in for operation.

3. Use the Miter Gauge for added control of the

work piece during sanding. The miter gauge can

also be set to various degree angles for maintain

-

ing accurate angles when sanding small or

multiple parts.

4. Do not force the work piece into the sanding

disc. Sand using light pressure, letting the sand

-

ing abrasives time to do their work!

5. Move your work piece slightly left and right on

the disc, keeping to the left-of-center, downward

side. This will help prevent resin or debris from

building up on one area of the disc, and also

helps to prevent burning of the sanded surface

from excessive abrasive-action heat build-up.

FIG. 16

FIG. 17

FIG. 18

OPERATION

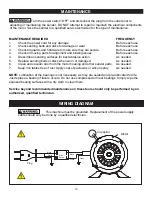

When sanding, always position

your work on the downward, rotating side (left

side) of the sanding disc. FIG. 16. The sanding

action will then force the wood down, safely

towards the table, where it can be controlled.

Sanding on the right, upward rotating side of

the disc is dangerous, as your work cannot be

controlled and ‘kick-back’ may occur - the wood

being forced up and out of your hands.

Always ensure the sander is

unplugged prior to attempting any assembly,

installation or changing of parts and accessories.

NOTE:

It is strongly recommended that users

employ a dust-collection system when using this

belt & disc sander. Use of a dust mask or res

-

pirator is still recommended, even when a dust

collection system is in use.