FIG. A

FIG. B

10

ASSEMBLY

ASSEMBLY AND INSTALLATION

Always ensure the sander is

unplugged prior to attempting any assembly,

installation or changing of parts and accessories.

MOUNTING THE SANDER TO A WORKBENCH

CAUTION:

If during operation there is any tendency

for the sander to tip over, slide or walk on the

supporting surface, the sander should be properly

mounted to a workbench or stand.

1. Rubber feet are fastened to this sander prior

to shipping. They may, or may not, be used when

attaching the sander to a bench or stand.

2. Position the sander on the workbench.

3. Mark the workbench through the two mounting

holes located in the left and right sides of the sander

base (between the holes for rubber feet).

4. Drill holes in the workbench at the 2 marks.

5. Using long bolts, washers, lock-washers and nuts;

or lag bolts; (fasteners not supplied), secure the

sander to the workbench. FIG. A.

DUST CHUTE INSTALLATION – DISC SANDER

1. Fasten the sanding disc dust-chute and cover

(Part #56) to the machine using the three Phillips M4

screws and washers (#21, 23). FIG. B.

ASSEMBLING THE BELT SANDER TABLE

When assembling the belt & disc

sander, ensure the machine is disconnected from any

power source.

1. Locate the round shaped belt-sanding table (#41).

2. Position the table by threading the belt and plate

through the table’s slot and square opening.

3. Fasten the table to the frame by using the table-

adjustment knob and 8mm washer (#43, 42). FIG. C.

4. Bring the adjustment knob’s screw through the slot

in the bracket opening on the underside of the table,

then into the threaded hole in the frame that houses

the hex nut (#17).

5. Fasten the table in place by using the adjustment

handle to turn its integral screw into the nut.

FIG. C

Dust Chute

Table

Adjustment

Knob

Lag Bolt

Machine Bolt

Washer

Machine Base

Rubber Foot

Washer

Lock Washer

Nut

Pilot Hole for

Lag Bolt

Workbench

Summary of Contents for 50-151

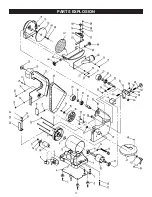

Page 17: ...PARTS EXPLOSION 17...

Page 19: ...WARRANTY 19 WARRANTY...