SYMPTOM

PROBABLE CAUSE

CORRECTIVE ACTION

Burn marks on workpiece.

1. Using a sanding grit that is too

fine.

2. Using too much pressure.

3. Work held still for too long

against the sandpaper.

1. Use a coarser-grit sandpaper.

2. Reduce work piece pressure on

the sandpaper while sanding.

3. Do not keep the work piece sand-

ing in one place for too long.

Deep sanding grooves or

scars in work piece.

1. Sanding belt/disc grit is too

coarse for the desired finish.

2. Work piece is being sanded

across the grain.

3. Too much sanding force on the

work piece.

4. Work piece held still against the

belt-disc for too long.

1. Use a finer-grit sanding belt or

disc.

2. Sand with the grain of the wood.

3. Reduce pressure on workpiece

while sanding.

4. Keep work piece moving while

sanding.

Sanding surface clogs

quickly.

1. Too much pressure against the

belt or disc.

2. Sanding softwood or highly

resinous woods.

1. Reduce pressure on work piece

while sanding.

2. Use different stock, sandpa-

per grits, or accept that this will

happen and plan on cleaning or

replacing belts & discs frequently.

Sanding grains easily rub

off the belt or disc.

1. Sandpaper has been stored in

an incorrect environment.

2. Sandpaper has been damaged

or folded.

1. Ensure sandpaper is stored

away from extremely hot & dry

or damp/humid conditions.

2. Store sanding accessories flat –

not bent or folded.

Workpiece lifts up from the

sanding disc-table.

1. Sanding on the “up” , right side

of the disc, where rotation is

up and away from the table.

1. Sand on left side of sanding disc,

where the disc rotates down

towards the table.

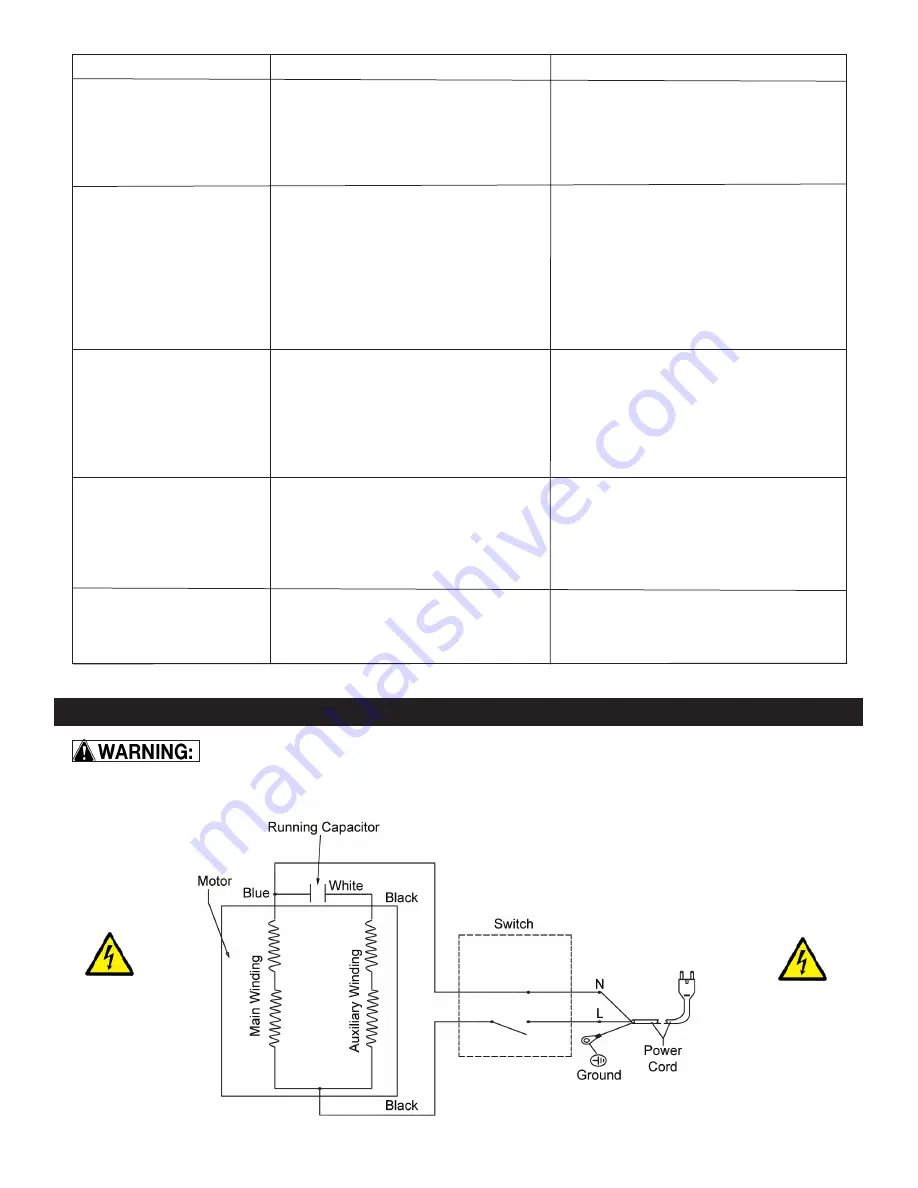

WIRING DIAGRAM

This machine must be grounded. Replacement of the power supply cable should only be

done by a qualified electrian. Read the Electrical Safety Information on pages 5 and 6 for further information.

16

Summary of Contents for 50-151

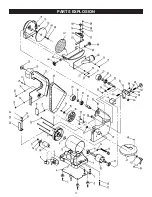

Page 17: ...PARTS EXPLOSION 17...

Page 19: ...WARRANTY 19 WARRANTY...