2

TABLE OF CONTENTS

SPECIFICATIONS

Specifications ........................................................................................................................................2

Safety Instructions..............................................................................................................................3 - 6

Electrical Requirements ..............................................................................................................5, 6, 16

Sander Safety Rules .......................................................................................................................7

Contents of Package ............................................................................................................................................8

Getting to Know Your Sander .................................................................................................................................9

Assembly ...........................................................................................................................9 - 11

General Use............................................................................................................11 - 14

Maintenance ...................................................................................................................................14

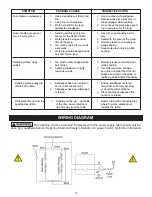

Trouble Shooting........................................................................................................................................15 - 16

Wiring Diagram.................................................................................................................................16

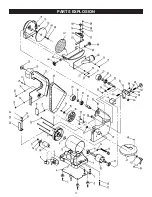

Parts Explosion................................................................................................................................17

Parts List .....................................................................................................................................18

Warranty .............................................................................................................................................19

1/3 HP

3450 RPM

120 V

2.3 A, 60 Hz

1” x 30”

3340 SFPM

5” Diameter

3350 RPM

PSA

(Pressure Sensitive Adhesive)

5-3/4” Diameter, Tilts 45

o

Motor

Motor Speed (no load)

Volts

Amps, Hertz

Belt Size

Belt Speed (no load)

Disc Size

Disc Speed (no load)

Disc Type

Belt Table Size

7-1/4” x 3-7/8”, Tilts 45

o

1-1/2” Diameter (2)

8-1/4” x 6”

15 lbs 6 oz

Disc Table Size

Dust Ports

Base Size

Net Weight

NOTE:

The specifications, photographs, drawings and information in this manual represent the current

model when the manual was prepared. Changes and improvements may be made at any time, with no

obligation on the part of Rikon Power Tools, Inc. to modify previously delivered units. Reasonable care

has been taken to ensure that the information in this manual is correct, to provide you with the guidelines

for the proper safety, assembly and operation of this machine.

This owner’s manual is not a teaching aid and is intended to show

assembly, adjustments, and general use.

Summary of Contents for 50-151

Page 17: ...PARTS EXPLOSION 17...

Page 19: ...WARRANTY 19 WARRANTY...