6

SAFETY INSTRUCTIONS

ELECTRICAL SAFETY

(Continued)

DO NOT MODIFY THE PLUG PROVIDED.

If it will not fit the electrical receptacle, have the proper

electrical receptacle installed by a qualified electrician.

IMPROPER ELECTRICAL CONNECTION

of the

equipment grounding conductor can result in risk of

electric shock. The conductor with the green insulation

(with or without yellow stripes) is the equipment grounding

conductor.

DO NOT

connect the equipment grounding

conductor to a live terminal if repair or replacement of the

electric cord or plug is necessary.

CHECK

with a qualified electrician or service personnel if

you do not completely understand the grounding

instructions, or if you are not sure the tool is properly

grounded.

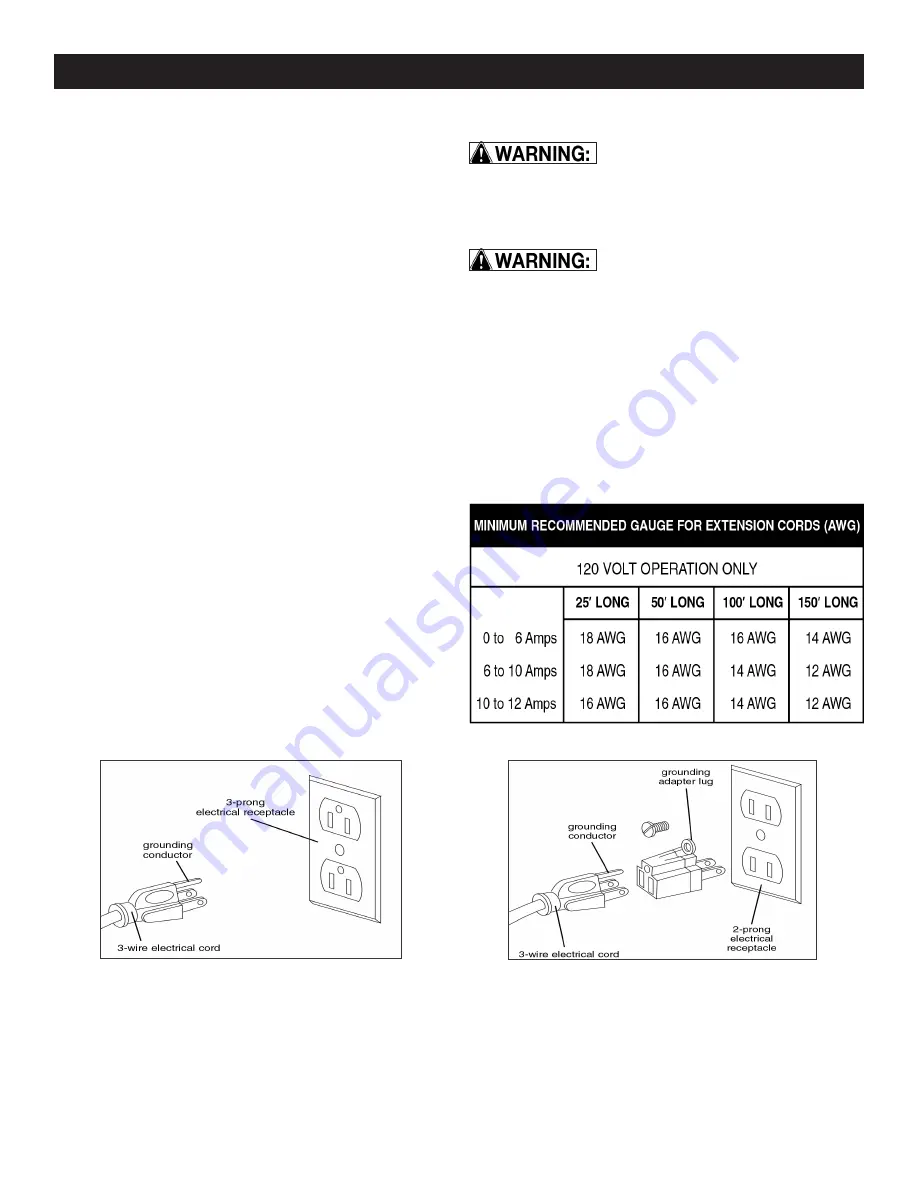

USE ONLY A 3-WIRE EXTENSION CORD THAT HAS A

3-PRONG GROUNDING PLUG AND A 3-POLE

RECEPTACLE THAT ACCEPTS THE TOOL’S PLUG.

REPLACE A DAMAGED OR WORN CORD

IMMEDIATELY.

This tool is intended for use on a circuit that has an

electrical receptacle as shown in

FIGURE 1. FIGURE 1

shows a 3-wire electrical plug and electrical receptacle that

has a grounding conductor. If a properly grounded electrcal

receptacle is not available, an adapter as shown in

FIGURE 2

can be used to temporarily connect this plug to

a 2-contact ungrounded receptacle. The adapter has a rigid

lug extending from it that MUST be connected to a

permanent earth ground, such as a properly grounded

receptacle box.

THIS ADAPTER IS PROHIBITED IN

CANADA.

EXTENSION CORDS

Keep the extension cord clear of the

working area. Position the cord so that it will not get

caught on lumber, tools or other obstructions while

you are working with a power tool.

Check extension cords before each

use. If damaged replace immediately. Never use a tool

with a damaged cord, since touching the damaged

area could cause electrical shock, resulting in serious

injury.

Use a proper extension cord. Only use cords listed by

Underwriters Laboratories (UL). Other extension cords can

cause a drop in line voltage, resulting in a loss of power

and overheating of tool. When operating a power tool

outdoors, use an outdoor extension cord marked “W-A” or

“W”. These cords are rated for outdoor use and reduce the

risk of electric shock.

Figure 1

Figure 2

Summary of Contents for 50-151

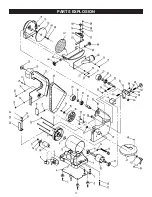

Page 17: ...PARTS EXPLOSION 17...

Page 19: ...WARRANTY 19 WARRANTY...