Fitting the battery: Make sure the battery is the correct way up (as per 5.2) and then slide into

the bower until the battery catch engages. It is essential that the battery catch is fully locked.

7. Maintenance / Cleaning:

The Blower unit, filter housing and head units must all be regularly cleaned to keep them in

good working order.

For single users, the units can all be cleaned with a cloth moistened with luke warm water and

soap.

For multiple users, the units should be disinfected when passed from one user to another.

SISAB recommends that ‘Incidur’ from Ecolad GmbH & Co. OHG is used for disinfecting.

Liquids must not be allowed to enter the workings of the blower unit or get on to the element of

the filter.

Parts should be allowed to air dry. Under no circumstances should any solvents or abrasive

cleaning agents be used. The unit must not be dried using hot air or radiant heat.

The unit should continue to provide protection to the designed specification for 2 to 3 years,

when maintained in accordance with these instructions. Prior to each use the user should check

that the unit is free from defects, such as cracks, split filters and hoses, cracked visors and

helmet components as appropriate

8. Fault finding:

If there is a sudden change in air supply while using the CR-2B01/2013 system, it is necessary

to check the following:

· That all parts of the air-supply system are assembled properly.

· The battery and its connector.

· Whether the charger is not faulty or malfunctioning (if so, diodes do not work).

· Filters and their clogging.

· That there is not a hole in the air hose.

· Whether the hood seal is not damaged.

· Whether the working time after a full recharging of the battery has not decreased (if so, it is

necessary to replace the battery).

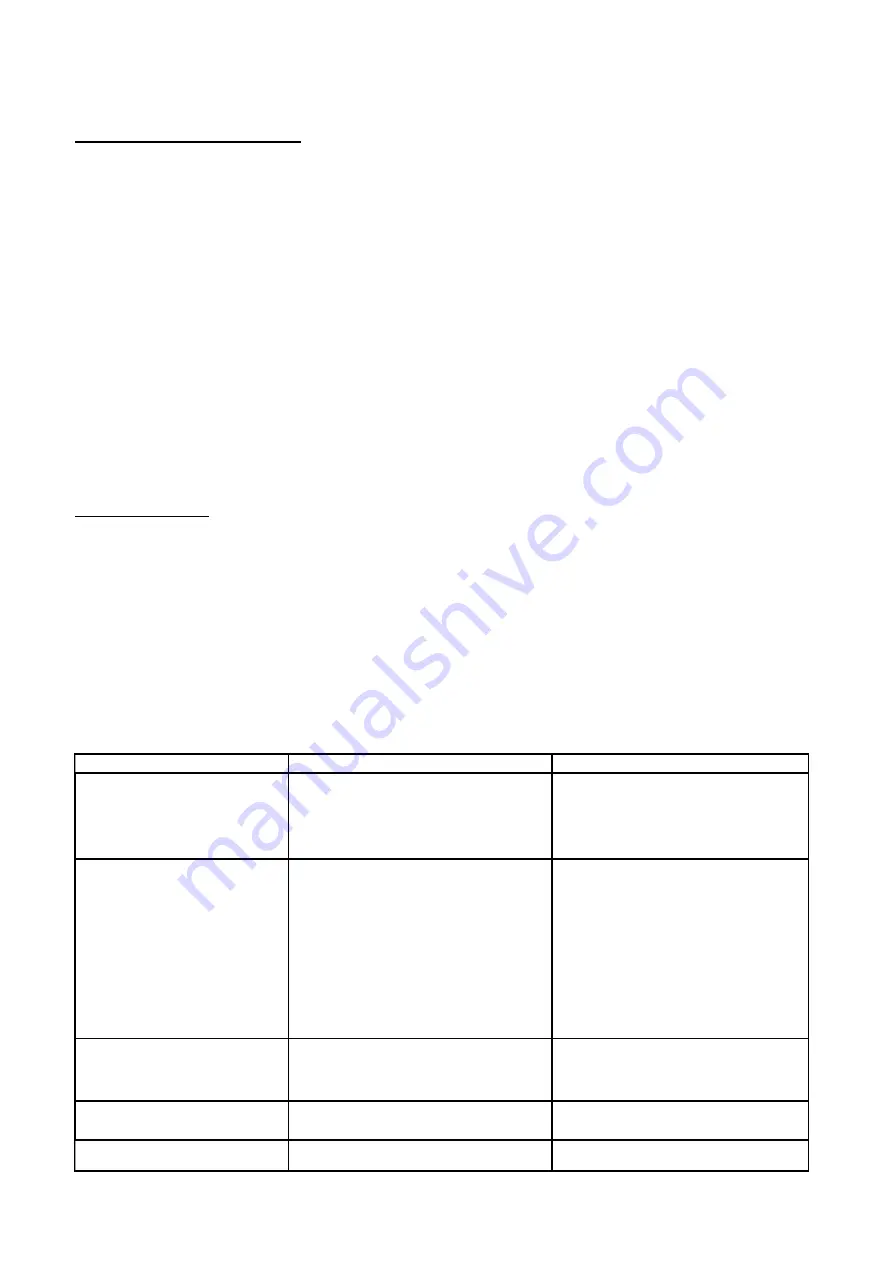

Fault

Probable reason

Recommendation

The blower unit does not work at

all

Entirely discharged battery.

(verify if the blower unit works with

another charged battery)

Faulty motor, circuit board or connector

Charge the battery.

(if problem persists, check the battery)

Contact your supplier.

Low airflow

Blocked air hose or airduct.

Leakage

Battery is not charged enough.

Blocked Filter or Pre Filter

Check and remove blockage.

Check all seals, connectors and the air

hose. Make sure that air can not leak

through holes or tears.

Charge the battery

(if problem persists, check the battery)

Change the Pre – Filter. Then if the

problem persists change the main filter.

Short operating time.

Clogged Filter.

Battery is not charged properly.

Change the filters

Charge the battery.

(If problem persists, check the battery)

Battery cannot be charged.

Battery contact is damaged.

Charger is faulty.

Check the battery contact.

Contact your supplier.

Battery cannot be charged

sufficiently.

Battery is worn out..

Install a new battery.