- 6 -

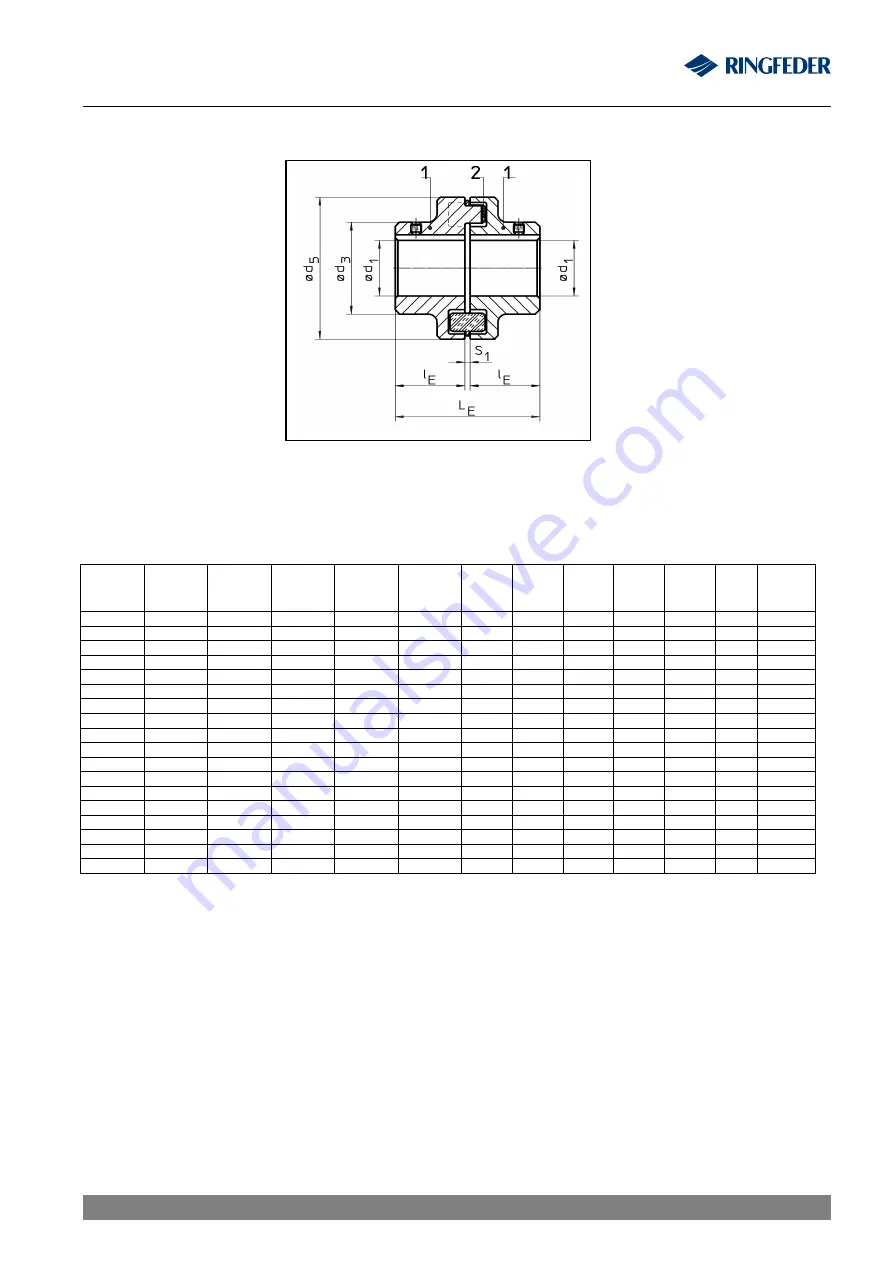

6 Technical data

Table 1

Technical data:

Size

TNM

E

T

Cnom

Pb72

[Nm]

T

Cpeak

Pb72

[Nm]

T

Cnom

Pb82

[Nm]

T

Cpeak

Pb82

[Nm]

n

max

[min

-1

]

d

1

max

[mm]

d

3

[mm]

d

5

[mm]

l

E

[mm]

L

E

[mm]

S

1

[mm]

m

unbored

[kg]

50

13

27

20

45

12500

19

33

50

25

52,0

2,0

0,4

67

22

45

35

75

10000

28

46

67

30

62,5

2,5

1,0

82

48

100

75

160

8000

32

53

82

40

83,0

3,0

1,8

97

96

200

150

340

7000

42

69

97

50

103,0

3,0

3,4

112

150

310

230

540

6000

48

79

112

60

123,5

3,5

5,3

128

250

500

380

860

5000

55

90

128

70

143,5

3,5

8,2

148

390

800

600

1350

4500

65

107

148

80

163,5

3,5

12,7

168

630

1300

980

2250

4000

75

124

168

90

183,5

3,5

19,3

194

1050

2000

1650

3630

3500

85

140

194

100

203,5

3,5

27,8

214

1500

3100

2400

5400

3000

95

157

214

110

224,0

4,0

38,2

240

2400

4800

3700

8650

2750

110

179

240

120

244,0

4,0

53,4

265

3700

7500

5800

13500

2500

120

198

265

140

285,5

5,5

75,0

295

4900

10000

7550

18000

2250

130

214

295

150

308,0

8,0

95,7

330

6400

13000

9900

23400

2000

150

248

330

160

328,0

8,0

132,9

370

8900

18200

14000

32750

1750

170

278

370

180

368,0

8,0

187,7

415

13200

27000

20500

49000

1500

190

315

415

200

408,0

8,0

259,3

480

18000

36000

28000

66000

1400

210

315

415

220

448,0

8,0

328,7

575

27000

54000

41000

97500

1200

230

350

575

240

488,0

8,0

466,9

The torque T

Cnom

and T

Cpeak

is valid for:

-

Intermediate rings of Perbunan Pb72 and/or Pb82,

-

Ambient temperatures of -40 °C to +60 °C,

-

Operation within the stipulated alignment values.

During the layout of the coupling according to DIN 740 part 2 (or also

Product Paper & Tech

Paper ”Elastomer Jaw Couplings“

) different factors must be considered:

-

with higher temperatures a corresponding temperature factor S

υ

-

according to the starting frequency a starting factor Sz

-

in dependence of the operating conditions an impact factor, S

A

, S

L

With circumferential speeds of more than 22 m/s, we recommend to balance the coupling.

Fig. 2

RINGFEDER

®

TNM E

RINGFEDER

®

TNM E

BAWN 001-

GBR

-1