- 18 -

9.1 Sense of rotation test

Injury danger!

Switch-off the drive before all work on the coupling!

Secure the drive against unintentional switching on and rotating!

Due to incorrectly screwed on screws, parts can fly away and

cause person and material damage!

Check before commissioning the coupling the alignment and all

screw fixings for their specified tightening torque and/or firm seat-

ing!

Before commissioning the plant all protective devices against

unintentional touching of free moving and/or rotating parts must be

installed.

To avoid sparks coverings should be made of stainless steel!

The coverings must fulfil at least the protection type IP2X.

The covering is to be designed in such a way that it does not

deposit dust onto the coupling parts.

The covering must not touch the coupling and/or influence it in its

function.

Attention!

A sense of rotation test can only be carried out if the coupling

flange is mounted onto the aggregate drive-side! Otherwise spark-

ing hazards exist through the pushed back claw ring!

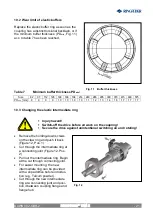

Remove the fixing screws on the

claw ring and push it back (Figure 9,

Pos. 1).

Secure the claw ring against uninten-

tional displacement.

Cut through the intermediate ring at a

connecting part (Figure 9, pos. 2).

Pull out the intermediate ring. Start at

the cut through connecting part.

Attention!

Make sure, that the coupling halves can not move axially during the

sense of rotation test.

The coupling half with the pulled back claw ring must remain

stationary during the sense of rotation test.

The rotating half must not touch the stationary half!

Fig. 9

RINGFEDER

®

TNM E

BAWN 002-GBR-2