- 6 -

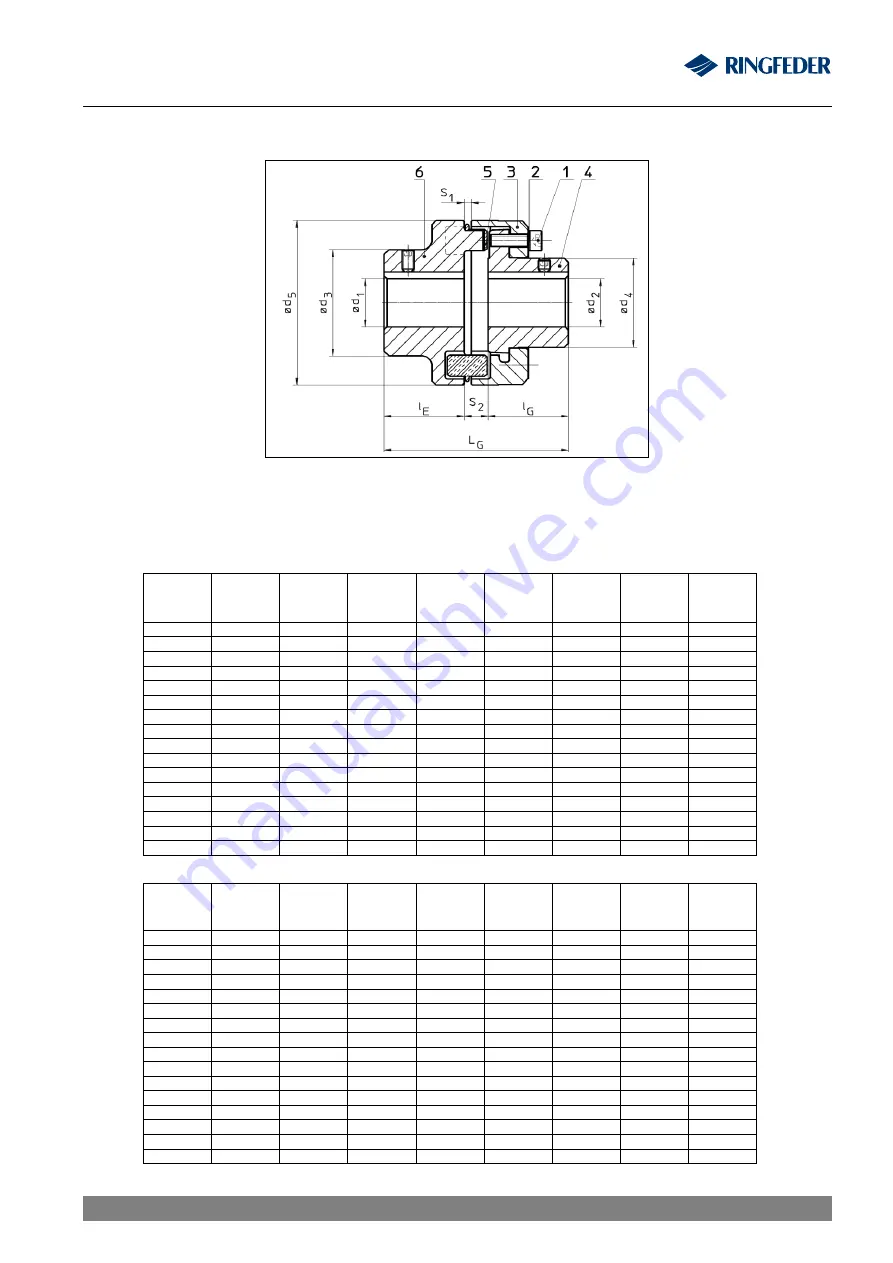

6 Technical data

Table 1

Technical data:

Size

TNM

G

T

Cnom

Pb72

[Nm]

T

Cpeak

Pb72

[Nm]

T

Cnom

Pb82

[Nm]

T

Cpeak

Pb82

[Nm]

n

max

[min

-1

]

d

1

max

[mm]

d

2

max

[mm]

d

3

[mm]

82

48

100

75

150

8000

32

32

53

97

96

200

150

210

7000

42

39

69

112

150

310

230

540

6000

48

46

79

128

250

500

380

650

5000

55

53

90

148

390

800

600

1350

4500

65

65

107

168

630

1300

980

1800

4000

75

75

124

194

1050

2000

1650

2400

3500

85

85

140

214

1500

3100

2400

4200

3000

95

95

157

240

2400

4800

3700

6200

2750

110

100

179

265

3700

7500

5800

8300

2500

120

115

198

295

4900

10000

7550

10500

2250

130

130

214

330

6400

13000

9900

14500

2000

150

135

248

370

8900

18200

14000

20000

1750

170

160

278

415

13200

27000

20500

27000

1500

190

180

315

480

18000

36000

28000

66000

1400

210

200

315

575

27000

54000

41000

97500

1200

230

260

350

Size Nor-

Mex G

d

4

[mm]

d

5

[mm]

l

E

[mm]

l

G

[mm]

L

G

[mm]

S

1

[mm]

S

2

[mm]

m

undrilled

[kg]

82

44,5

82

40

40

92

3,0

12

2,0

97

54,5

97

50

49

113

3,0

14

3,4

112

64,5

112

60

58

133

3,5

15

5,5

128

74,5

128

70

68

154

3,5

16

8,3

148

92,5

148

80

78

176

3,5

18

13,1

168

104,5

168

90

87

198

3,5

21

19,4

194

121,5

194

100

97

221

3,5

24

28,5

214

135,5

214

110

107

243

4,0

26

38,8

240

146,0

240

120

117

267

4,0

30

52,4

265

164,0

265

140

137

310

5,5

33

75,3

295

181,0

295

150

147

334

8,0

37

97,3

330

208,0

330

160

156

356

8,0

40

130,0

370

241,0

370

180

176

399

8,0

43

183,6

415

275,0

415

200

196

441

8,0

45

258,2

480

289,0

480

220

220

485

8,0

45

346,5

575

370,0

575

240

240

525

8,0

45

528,8

Fig. 2

RINGFEDER

®

TNM G

RINGFEDER

®

TNM E

BAWN 002-GBR-2