- 17 -

9.1 Check of Direction of Rotation

§

Injury danger!

§

Switch-off the drive before all work on the coupling!

§

Secure the drive against unintentional switching on and rotating!

§

Due to incorrectly screwed on screws, parts can fly away and

cause person and material damage!

§

Check before commissioning the coupling the alignment and all

screw fixings for their specified tightening torque and/or firm seat-

ing!

§

Before commissioning the plant all protective devices against

unintentional touching of free moving and/or rotating parts must be

installed.

§

To avoid sparks coverings should be made of stainless steel!

§

The coverings must fulfil at least the protection type IP2X.

§

The covering is to be designed in such a way that it does not

deposit dust onto the coupling parts.

§

The covering must not touch the coupling and/or influence it in its

function.

·

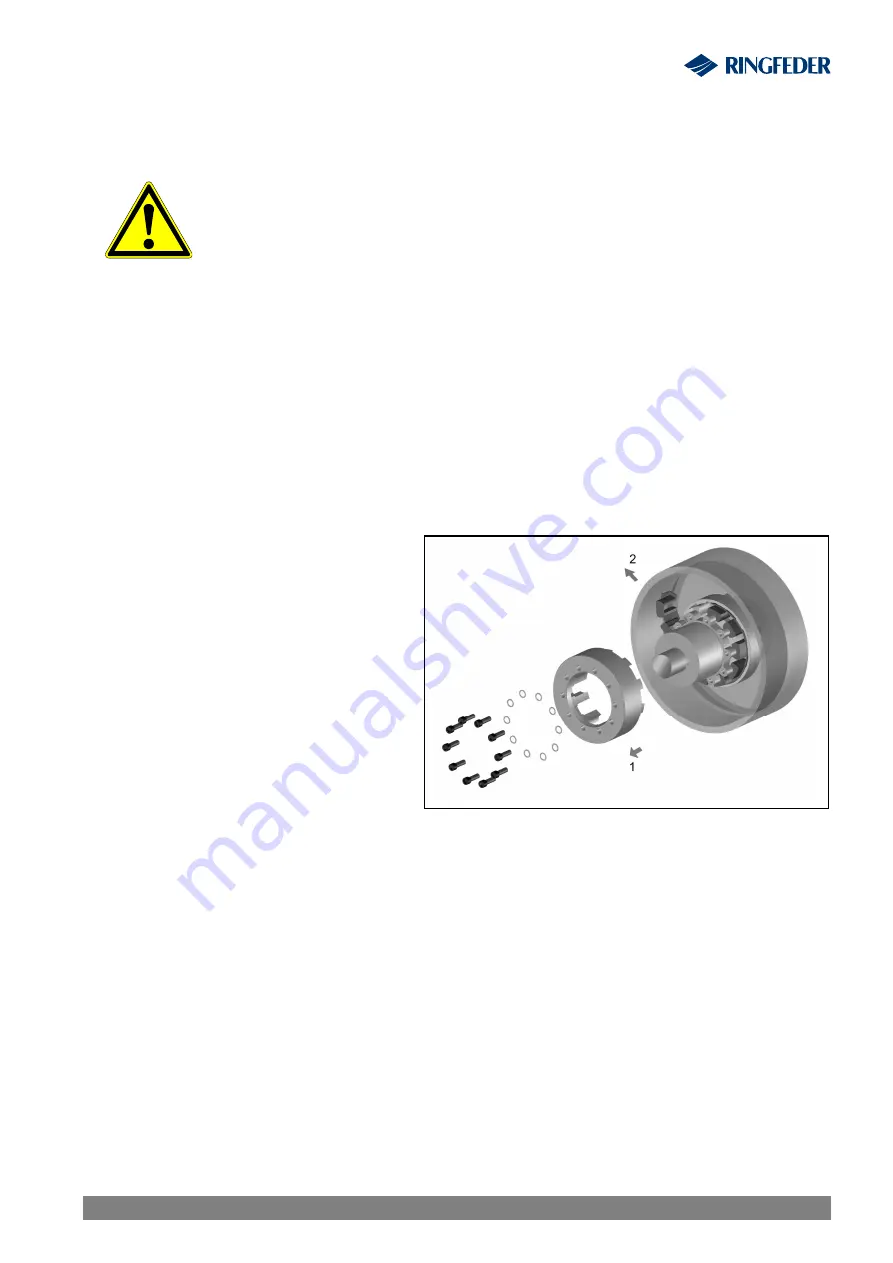

Remove the fixing screws on the

claw ring and push it back (Figure 9,

Pos. 1).

·

Secure the claw ring against uninten-

tional displacement.

·

Cut through the intermediate ring at a

connecting part (Figure 9, pos. 2).

·

Pull out the intermediate ring. Start at

the cut through connecting part.

·

Attention!

·

Make sure, that the coupling halves can not move axially during the

sense of rotation test.

·

The coupling half with the pulled back claw ring must remain

stationary during the sense of rotation test.

·

The rotating half must not touch the stationary half!

·

Check the direction of rotation.

·

Cut through a new intermediate ring at a connecting part and fit it between coupling hub

and flange.

·

To obtain an easier mounting one can provide the new elastic intermediate ring with a slip

additive before its introduction (e.g. talcum powder).

Fig. 9

RINGFEDER

®

TNM GBT, TNM GTW

BAWN 006-

GBR

-1