- 11 -

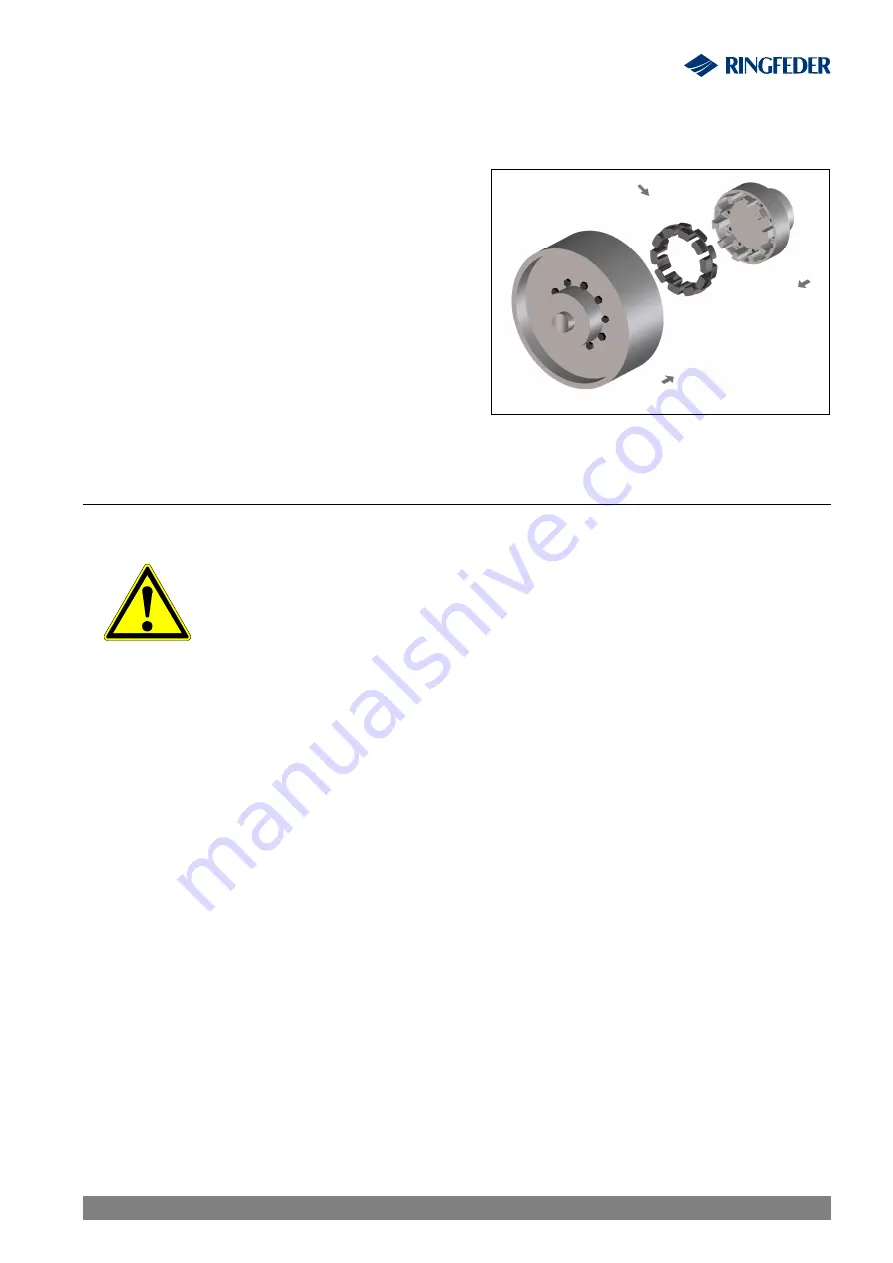

Fig. 5

ATTENTION!

Let the hot hub cool off to ambient temperature before the introduction of the interme-

diate ring.

·

For easier mounting the elastic intermediate

ring can be provided with a slip additive (e.g.

Talcum) before introduction.

·

Fit the intermediate ring into one half of the

coupling

·

Push the shaft end with the mounted

coupling halves together (Figure 5).

·

Adjust the coupling according to the follow-

ing specifications in “8 Coupling adjustment”.

8 Adjusting coupling

§

Injury hazard!

§

Switch-off the drive before all work on the coupling!

§

Secure the drive against unintentional switching on and rotating!

§

Reference:

§

An exact alignment of the coupling increases the service life of the

elastic intermediate ring.

§

Do not exceed the maximum permissible displacement values. The

overstepping of these values results in coupling damage and

breakdown!

·

When aligning the cold equipment take into account the expected thermal growth of the

components, so that the permissible misalignment values for the coupling are not

exceeded in operation.

·

Be aware that the coupling under misalignment imposes restoring forces on the adjacent

shafts and bearings. Take into account that the larger the misalignment, the greater the

restoring forces will be.

·

The displacements values indicated in the tables 4 to 6 are maximum permissible guide

numbers.

We recommend not to fully utilise these values during the alignment, so that in operation

sufficient reserves remain for thermal expansions, foundation settlements etc.

·

In special cases with high demands on quiet running or high rotating speeds it is possible

that, in the three displacement levels, an alignment accuracy of

£

0,1 mm is necessary.

·

If the coupling is mounted in a closed housing / casing so that a subsequent alignment is

not possible any more, it must be guaranteed that the geometry and fit accuracy of the

contact surfaces in operation aligns the shafts exactly within the mentioned tolerances.

RINGFEDER

®

TNM GBT, TNM GTW

BAWN 006-

GBR

-1