Oil Lubrication

Use oils selected from the following table according to

the application and ambient temperature existing at the

freewheel.

Note:

FRS and FRZ-300 thru 1000 freewheels are

shipped from Ringspann half full of Dexron III Automatic

Transmission Fluid.

For applications where the ambient temperature

e150°F (+65°C) consult Ringspann.

Do not use lubricants of the EP type

(extreme pressure characteristics) or those

containing slippery additives such as sulfur

phosphate, graphite, or molybdenum disulphide

.

Temp. Range Recommended Oil Lubricant

0°F to 150°F

MOBIL Multi-Purpose ATF (Dexron III)

TEXACO Havoline ATF (Dexron III)

CHEVRON ATF (Dexron III)

-20°F to 60°F

MOBIL DTE-15M

TEXACO Rando-HDZ 46

CHEVRON Hydraulic Oil AW MV 46

-50°F to 32°F

MOBIL Aero HF

TEXACO Aircraft Hydraulic Oil 5606G

CHEVRON Aviation Hydraulic Oil A

Important:

Do not mix oils. When switching from one

brand or type to another, drain old oil and flush

freewheel with mineral spirits, such as MOBIL

SOLVASOL or equivalent. Do not use any solvent

containing Carbon Tetrachloride.

The use of lubricants in freewheel

assemblies, other than shown, can compromise proper

function that may cause personal injury or property

damage and will automatically void any warranty.

Ringspann is not responsible for any lubrication changes

made after the freewheel leaves our factory.

Oil Lubrication Maintenance

1.

Inspect the oil level once a month or every 160

hours of operation, whichever occurs first. Indexing

applications that operate in excess of 150 strokes

per minute and severe duty applications may require

more frequent oil level inspection.

2.

Add oil if necessary to maintain the proper level.

Overrunning, Backstopping....... 1/2 full

Indexing.................................... 7/8 full

3.

To assure continued efficiency of operation, flush

freewheel every 6 months with mineral spirits.

Do not use any solvent containing Carbon

Tetrachloride as seal damage may occur.

Important:

Under severe operating conditions, such

as heavy dust or twenty-four hours per day

operation, flushing may be required at shorter

intervals.

Flushing will remove waxes and gums formed by

vaporization of the oil and helps assure continued

efficiency of operation. See “Flushing Procedure”.

4.

Flush with mineral spirits and relubricate before use

if freewheel has been out of service or in storage for

six months or more. Use recommended oils only.

In cases of dirty or abrasive environment or severe

operating conditions (24 hours per day), it is

recommended that oil be changed every month.

5.

If the freewheel is out of service or in storage for two

years or more, new seals should be installed before

freewheel is put into service.

Oil Lubrication – Filling Procedure

Overrunning and Backstopping Applications

1.

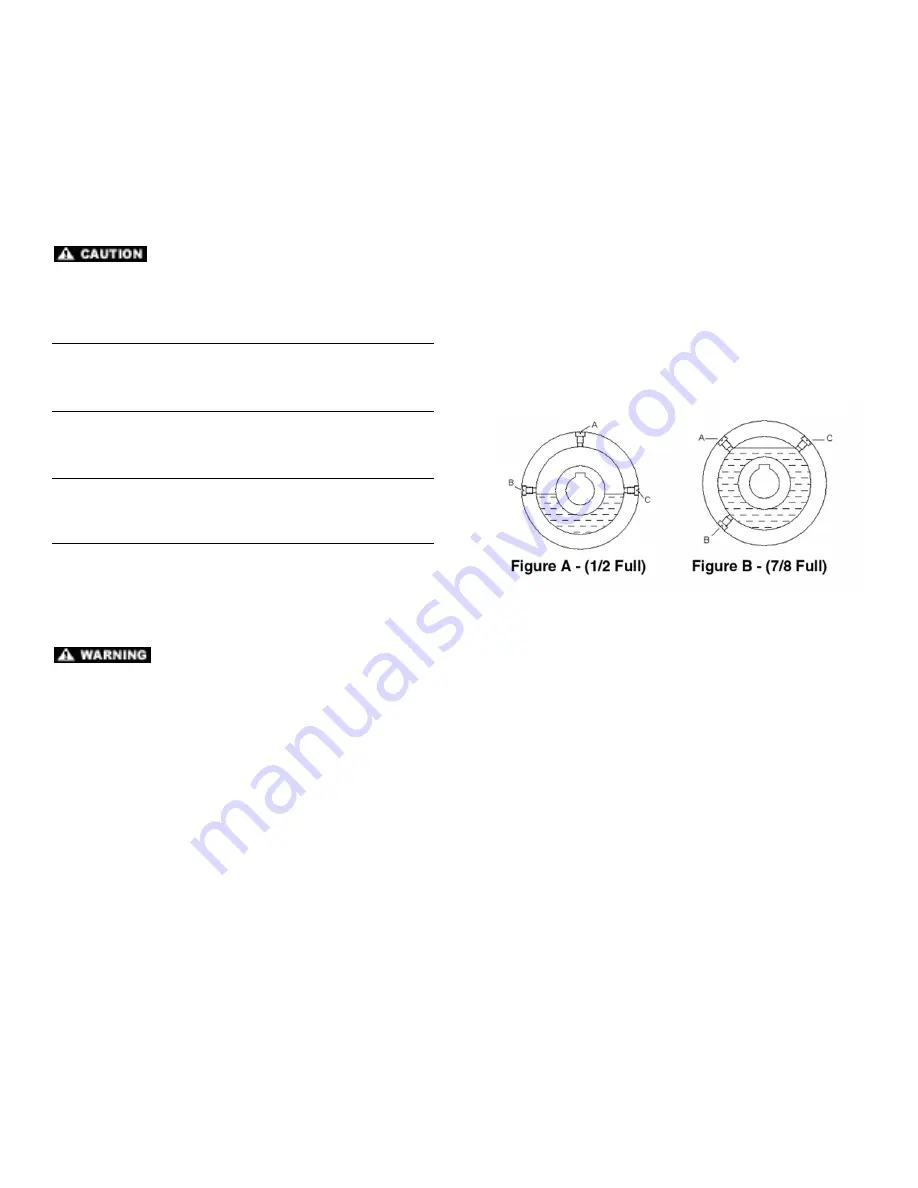

Rotate freewheel outer ring as shown in Figure A.

2.

Remove (A) and (B) plugs and add oil through (A)

until oil flows from (B). The freewheel is now 1/2 full.

3.

Reinstall (A) and (B) plugs with sealing washers and

tighten to prevent leakage.

Indexing Applications (up to 150 strokes per minute)

Note: Contact Ringspann for indexing applications in

excess of 150 strokes per minute

1.

Rotate freewheel outer ring as shown in Figure B.

2.

Remove (A) and (C) plugs and add oil through (A)

until oil flows from (C). The freewheel is now 7/8 full.

3.

Reinstall (A) and (C) plugs with sealing washers and

tighten to prevent leakage.

Flushing Procedure

1.

Rotate freewheel outer ring to locate plug (B) in the

6 o’clock position.

2.

Remove plug (B) and drain oil from freewheel.

Remove plug (C) for better drainage.

3.

Reinstall plug (B) and completely fill freewheel with

mineral spirits. Reinstall plug (C).