23

7.0 Start-Up and Commissioning

•

Ensure that a Return Air Filter is fitted prior to fan start up

•

Measure and record the system details as noted under PRELIMINARY SYSTEM INFORMATION and check all

items as noted under PRE START-UP on the Commissioning Sheet provided

•

Switch the unit on in cooling mode with the thermostat set to minimum temperature set point

•

Measure and record all items as noted under OPERATION CHARACTERISTICS on the Commissioning Sheet

provided

•

Check suction and liquid pressures

•

Care must be taken to charge the system correctly. Undercharge will result in lack of capacity and the unit may

lock out on its LP (Low Pressure) safety switch. Overcharge will result in high head pressures whilst unit is

operating

•

Measure the compressor suction pressure and convert to a compressor saturated suction temperature (CSST)

using R410a refrigerant pressure/temperature table

•

Measure the suction line temperature (SLT) approximately 100mm before the compressor

•

Calculate the superheat (SH) = SLT – CSST

•

Measure the compressor discharge pressure and convert to a condensing temperature (CT) using R410a

refrigerant pressure / temperature table

•

Measure the liquid line temperature (LLT) between the outdoor coil and indoor unit throttling device in cooling

mode

•

Calculate the sub-cooling (SC) = CT – LLT

•

Measure the outdoor ambient air temperature

•

Measure the indoor return and supply air dry bulb temperatures, both before and after the indoor coil

•

Measure the indoor air quantity ensuring it falls within the Indoor Coil’s limits

•

Adjust the fan speed to suit the static pressure and air quantity requirements

•

Allow system pressure to stabilise for a minimum of 20 minutes

•

Instruct the customer on system capability and correct operation

•

Please ask the customer to fill in the CUSTOMER DETAILS section and to register their product warranty with

Brivis

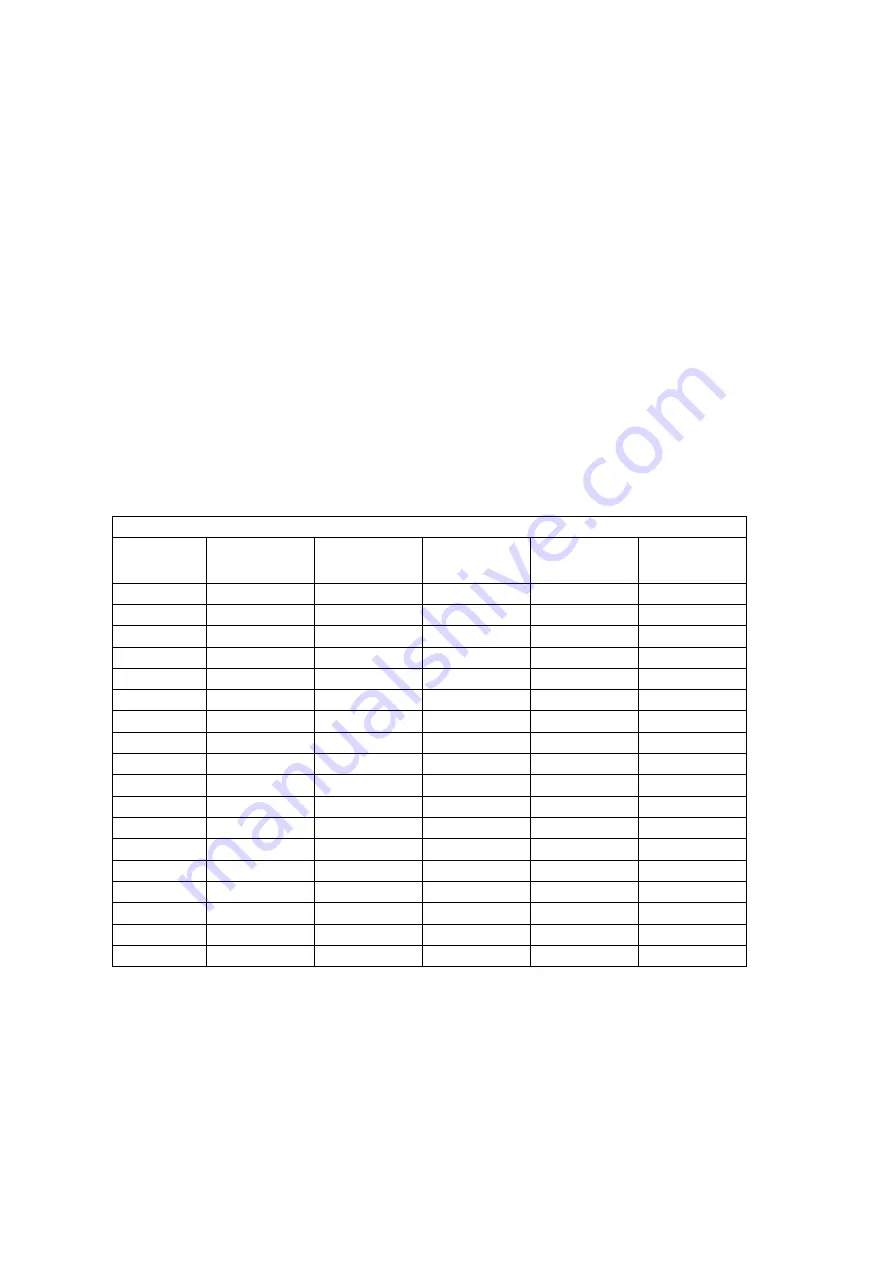

R410a Pressure-Temperature chart

Saturated

Temperature

°C

Gauge

Pressure

kPa

Saturated

Temperature

°C

Gauge

Pressure

kPa

Saturated

Temperature

°C

Gauge

Pressure

kPa

-40

79

-4

602

32

1866

-38

95

-2

648

34

1968

-36

113

0

697

36

2073

-34

132

2

749

38

2183

-32

152

4

803

40

2297

-30

174

6

859

42

2415

-28

196

8

918

44

2537

-26

221

10

980

46

2664

-24

246

12

1045

48

2796

-22

274

14

1113

50

2932

-20

303

16

1183

52

3073

-18

334

18

1257

54

3219

-16

366

20

1334

56

3371

-14

400

22

1414

58

3527

-12

436

24

1497

60

3689

-10

475

26

1584

62

3857

-8

515

28

1674

64

4031

-6

557

30

1768

66

4210

Table 5– Saturated Pressure-Temperature R410a

FAILURE TO COMPLETE PROPER START UP AND COMMISSIONING MAY VOID BRIVIS PRODUCT WARRANTY