1

Rinnai Corporation ES17 / ES22 Manual

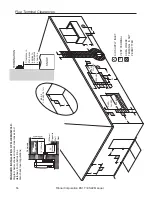

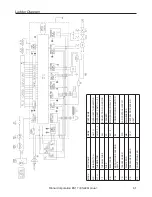

Dimensions

21 13/16" (554mm)

19 15/16" (506mm)

8 7/16"(214mm)

Power supply cable

29 1/2" (750mm)

8 9/16"

(217mm)

9 5/8"

(245mm)

Exhaust at rear of unit

3 7/16" (88mm)

11 " (280mm)

1"

(25mm)

3 3/8" (85mm)

6 1/2" (165mm)

R8.0"

(R206mm)

2 3/5"(66mm)

(R25

1mm)

R9

.9"

R10.6"

(R270mm)

17 16/25"(448mm)