16

Rinnai Corporation EX08CT, EX11CT Manual

□

Verify proper clearances around the vents and air

intakes.

□

Ensure you have used the correct venting

products for the model installed and that you have

completely followed the venting manufacturer

’

s

installation instructions and these installation

instructions.

□

Verify that the vent system does not exceed the

maximum length for the number of elbows used.

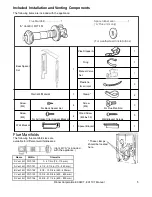

Checklist for Venting

Gas Connection

When connecting the gas valve or other gas

components in the gas line, use a backup wrench to

ensure the connection is gas tight.

WARNING

•

The gas supply line shall be gas tight, sized and so

installed as to provide a supply of a gas sufficient to

meet the maximum demand of the furnace without

loss of pressure.

•

A shut off valve and appliance connector valve

should be installed in the upstream of the gas line

to permit servicing.

•

Flexible pipe and any appliance connector valve

used for gas piping shall be types approved by

nationally recognized agencies.

•

Any compound used on the threaded joint of the

gas piping shall be a type which resists the action

of liquefied petroleum gas (propane).

•

After completion of gas pipe connections all joints

including the furnace must be checked for gas

tightness by means of leak detector solution, soap

and water, or an equivalent nonflammable solution,

as applicable. (Since some leak test solutions,

including soap and water, may cause corrosion or

stress cracking, the piping shall be rinsed with

water after testing, unless it has been determined

that the leak test solution is non

-

corrosive.)

•

Check the gas supply pressure immediately

upstream at a location provided by the gas

company. Supplied gas pressure must be within

the limits shown in the Specifications section.

•

Refer to an approved pipe sizing chart if in doubt

about the size of the gas line.

Adjust Gas Pressure Settings

Complete these instructions for altitude and vent

length.

(Default altitude: 0ft

-

2,000ft. Default vent length:

0

-

7ft+1 elbow )

For high altitude installations in Canada, the conversion

shall be carried out by a manufacturer

’

s authorized

representative, in accordance with the requirements of

the manufacturer, provincial or territorial authorities

having jurisdiction and in accordance with the

requirements of CAN/CGA

-

B149.1 or CAN/CGA

-

B149

installation codes.

CAUTION

Do not touch any other areas on the PC board

besides the

“

SW

”

switches while power is supplied to

the appliance. Parts of the PC board are supplied

with 120 volts AC.

CAUTION

Do not insert hands or objects into the circulation fans

while they are running. Injury or mechanical

malfunction may occur.

CAUTION

Do not touch the areas at or near the exhaust. This

area becomes very hot and could cause burns.

The regulator has been factory pre

-

set. If the

pressure is incorrect, check the supply pressure first,

before making any adjustments to the appliance.

Also, if the low control pressure cannot be obtained,

adjust the adjustment screw on the proportional valve

to roughly set pressure and then recheck both the low

and high fire pressures.

NOTICE

Summary of Contents for EX08CT

Page 34: ...34 Rinnai Corporation EX08CT EX11CT Manual Cut Away Diagram ...

Page 38: ...38 Rinnai Corporation EX08CT EX11CT Manual Parts List Liste de Pièces ...

Page 39: ...Rinnai Corporation EX08CT EX11CT Manual 39 Parts List Liste de Pièces ...

Page 40: ...40 Rinnai Corporation EX08CT EX11CT Manual Parts List Liste de Pièces ...

Page 41: ...Rinnai Corporation EX08CT EX11CT Manual 41 Parts List Liste de Pièces ...

Page 48: ...48 Rinnai Corporation EX08CT EX11CT Manual NOTES ...

Page 87: ...Manuel EX08CT EX11CT de Rinnai Corporation 87 NOTES ...

Page 88: ...107517 RHF265 1107X02 00 200000072 02 5 2018 ...