Rinnai Corporation EX17 / EX22 Manual

Extension Kit Installation

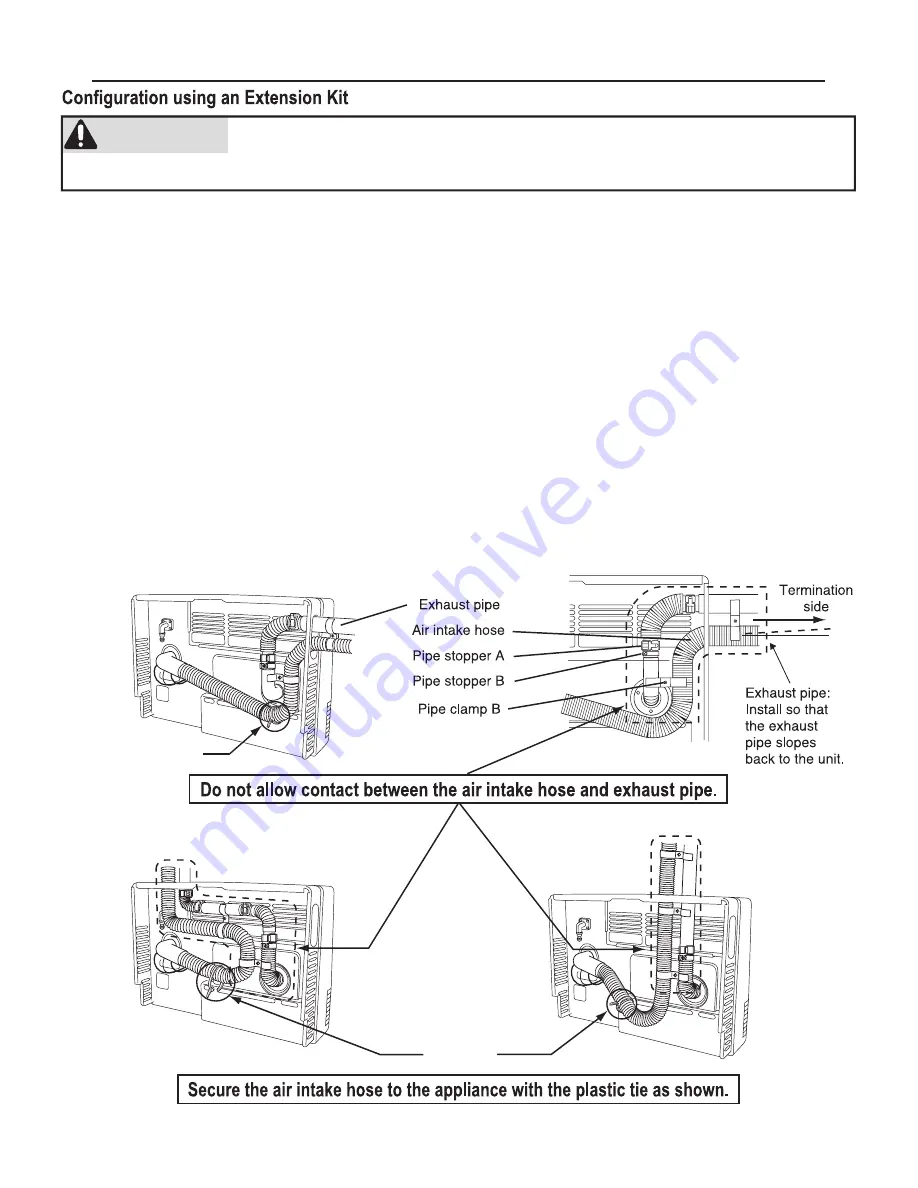

CAUTION

Secure the air intake hose and exhaust pipe with Pipe clamp B at intervals to

prevent contact between the air intake hose and the exhaust pipe.

If necessary, extension kits are available to extend the

exhaust line and air intake hose between the manifold

and the appliance.

(1) Maximum vent length allowed is 13 feet (4 m).

(2) Maximum vertical length allowed is 10 feet (3.0 m).

(3) Any length (horizontal and vertical) in excess of 10

feet (3.0 m) must be sloped 3° downward toward

the flue manifold to allow condensate to drain to

the outside.

(4) Do not allow any low points in the exhaust line

where condensate will collect.

(5) Vent extensions installed in unconditioned air

space must be insulated with high temperature

insulation and must be accessible.

(6) Vent extensions must not be concealed per NFPA

54 and must be accessible allowing inspection and

repair. Decorative covers are available from

Rinnai.

These figures show the 3 possible ways that the ex-

tension exhaust line and air intake hose may be di-

rected away from the appliance. All 3 views are from

behind the appliance.

For your configuration, position the air intake hose

as shown.

Horizontal extension on left side

right side

n

o

n

o

i

s

n

e

t

x

e

l

a

c

it

r

e

V

left side

n

o

n

o

i

s

n

e

t

x

e

l

a

c

it

r

e

V

Plastic tie

Plastic tie

Summary of Contents for EX17

Page 41: ...41 Rinnai Corporation EX17 EX22 Manual Cut Away Diagram ...

Page 43: ...43 Rinnai Corporation EX17 EX22 Manual Ladder Diagram ...

Page 44: ...44 Rinnai Corporation EX17 EX22 Manual Flow Diagram THERMISTOR ...

Page 46: ...46 Rinnai Corporation EX17 EX22 Manual Parts List ...

Page 48: ...48 Rinnai Corporation EX17 EX22 Manual Parts List ...