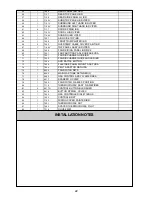

21

PARTS LIST

ITEM NO.

QTY.

PART NO.

DESCRIPTION

1

1

7993-1

FLUE SPIGOT ASSY NAT IB USA

2

1

7074

HEAT EXCHANGER FRONT ASSY 3+3H

3

1

7075

HEAT EXCHANGER REAR ASSY 3H

4

6

6624

BURNER EXCHANGER TRANSFER TUBE

5

2

6625

BURNER HEAT EXCHANGER BRACKET

6

1

7997

COMB CHAMB ASSY IBR US PAINTED

7

1

7195V

FRONT PANEL PAINTED VIPER IBR

8

1

7141

FAN QLN65/0030-3038LH MVL 110V

9

9

7130

FAN MTG SLEEVE

10

9

7129

FAN MTG GROMMET

11

9

9028

SCREW 8X5/8 MUSH HEAD 33611923

12

3

6651

CUSHION RUBBER REH210

13

1

7950

INJECTOR BLOCK BRKT FRONT MKII

14

1

7182

INJECTOR BRAY 420 CAT33 MULTI

NG

1

7175

INJECTOR BRAY 120 CAT23 SINGLE

LP

16

1

7341

INJECTOR BRAY 600 CAT33 MULTI

NG

1

7183

INJECTOR BRAY 200 CAT33 MULTI

LP

18

4

9064

SCREW M4 X 8 PHPMZ SPRINGWASH

19

1

7870

PILOT BODY TOP CONVERTIBLE

20

1

7871

PILOT CONVERTIBLE HOOD 2 FLAME

21

1

7875

ELECTRODE

22

1

7876

ELECTRODE NUT (S.I.T)

23

1

7986

ELBOW 6mmx1/8"BSPT BFM690602

24

1

7904

PILOT BRACKET FRONT USA

25

1

7873

INJECTOR LPG 31

NG

1

7872

INJECTOR NG 51

LP

27

1

7937

GAS SUPPLY TUBE A IBMAN

28

1

7938

GAS SUPPLY TUBE B IBMAN

29

1

7948

PILOT TUBE IBMAN US

30

1

7955

INJECTOR BLOCK A+B+D

31

1

7952

INJECTOR BLOCK A+B

32

1

7924

FRONT BURNER US ASSY PAINTED

33

1

4990

MAIN BURNER NG/LPG USA FLAME

34

1

7044

CERAMIC LOG SET c/w GRANULES

35

1

7258

AERATION SLEEVE SHORT

36

1

7564

ELECTRODE SLEEVE

37

2

7240

LOG LOCATING SLEEVE

38

2

9115

SCREW M5 X 25 PHSMZ PHIL

39

6

7029

LOUVRE TUBE FS 9.5 GOLD

40

1

7099

LOUVRE TUBE RD 15.8 GOLD

41

1

4996

GLASS PANEL ASSY IB/FS35

42

1

7004

BURNER DIVERT PANEL PTD ETR

43

1

7033

GLASS RET TOP ASSY PAINTED

44

1

7037

GLASS RET BOTTOM ASSY PAINTED

45

1

7920

FRONT PILOT SHIELD USA PAINTED

46

1

5327G

BRAND BADGE GOLD

47

3

6642

O RING REH210

48

2

7288

FAN MOUNTING BRACKET IBR

49

1

7072

FAN MTG PANEL IBR

50

1

7202

FAN PARTITION PANEL LOWER IBR

51

1

7220

FAN DIVIDING PANEL BRKT IB

52

1

7858

FAN PARTITION PANEL IBR ETR US

53

1

7208

FAN GUIDE TOP PAINTED IBR

54

1

7981

FAN DIVIDING BRKT.IB MAN USA