25

INSTALLATION INSTRUCTIONS

Clearance

The appliance must be in an accessible location. Sufficient clearances shall allow access to,

and removal of, all serviceable components. The following clearances should be followed.

Water Supply

Where the water supply pressure exceeds 10 bar, an approved pressure reducing device

must be fit at the inlet of the appliance. To achieve the maximum rated flow a minimum

water supply pressure of

2

.2 bar is required at the appliance inlet. The unit will operate at

lower supply pressures but the maximum flow rate will not be achieved. Most installations

will use high temperature set points which will reduce the available flow rate and heat

exchanger pressure drop, and therefore less pressure will be required at the inlet. See the

pressure chart on

page 53.

Contact Rinnai or your supplier for 'gravity fed' or 'low pressure'

hot water installations.

Water pipe sizing and layout should be designed correctly to ensure the given water flows

from the appliance are available. All hot water pipework should be insulated to optimise

maximum performance and energy efficiency.

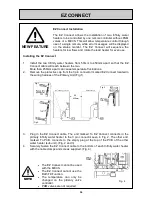

Water Connection

Connect the hot and cold water supply pipes as shown on

page 27.

An approved isolation

valve and strainer MUST be installed in the cold water inlet pipe. An approved isolation valve

and draining point should be installed in the hot water outlet pipe. There must be a union or

release fitting on the heater side of the isolation valves. An unvented kit to local regulations

must be installed in the pipework when the system is closed (i.e. has a flow and return, or

tank). Positions of the cold water inlet, hot water outlet and gas connections are shown on

page 42-43

.

If the heater is in a hard water area a suitable water conditioning device must be installed to

prevent the build up of limescale within the heat exchanger. Heat exchangers damaged by

scaling are not covered by the manufacturer’s warranty.

Gas Connection

Check pipe sizing required for the heater input. The heat input for the water heater is shown

on

page 44-45

. The size of the gas meter (or regulator) and pipework must be sufficient for

all appliances on the main. Sufficient gas must be available at the appliance if correct

operation is to be expected; insufficient gas will damage the unit. An approved gas isolation

valve must be fitted at the gas inlet. A union or release fitting should be installed after the

isolation valve.

Electrical Connection

The appliance must be earthed. The appliance is suitable for 23

0

VAC – 50Hz mains only

and all wiring must be carried out to local regulations.

Description

pH

Total Dissolved

Solids (TDS)

Total Hardness

Chlorides

Magnesium

Calcium

Sodium

Iron

Maximum Recommended

Levels

6.5 - 9.0

600 mg/litre

150 mg/litre

300 mg/litre

10 mg/litre

20 mg/litre

150 mg/litre

1 mg/litre

From Combustibles

From Non-Combustibles

Clearances in

mm

Internal Units

External Units

Internal Units

External Units

Above

300

300

50

50

Behind

0

0

0

0

In Front

600

600

600

600

Sides

50

150

15

15

Below

300

300

50

50

Flue pipe

0

-

0

-

Summary of Contents for R E U - K M2635FFUDHD-E

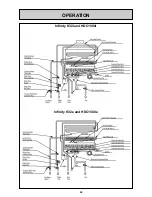

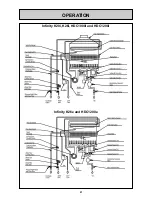

Page 20: ...20 OPERATION Infinity K32e and HDC1500e Infinity K32i and HDC1500i...

Page 21: ...21 OPERATION Infinity K26e and HDC1200e Infinity K20i K26i HDC1000i and HDC1200i...

Page 33: ...33 CONDENSATE DISPOSAL...

Page 42: ...42 DIMENSIONS Infinity K32i and HDC1500i Infinity K32e and HDC1500e...

Page 43: ...43 DIMENSIONS Infinity K20i K26i HDC1000i and HDC1200i Infinity K26e and HDC1200e...

Page 49: ...49 FLOW CHART...

Page 50: ...50 WIRING DIAGRAM Infinity K32 5 amp...

Page 51: ...51 WIRING DIAGRAM Infinity K20 K26 5AMP FUSE...

Page 52: ...52 DIAGNOSTIC POINTS Infinity K20 K26 Infinity K32 Y Y...

Page 53: ...53 WATER FLOW CHARACTERISTICS Infinity K32 Infinity K20 K26...

Page 54: ...54 LETTER OF COMPLIANCE...

Page 55: ...55 CE CERTIFICATE...

Page 56: ...56 CE CERTIFICATE...

Page 58: ...58 COMMISSIONING SHEET...

Page 59: ...59 SERVICE RECORD...