50

3.3 GAS CONVERSION AND PRESSURE ADJUSTMENT

This procedure can only be performed by qualified technical personnel.

Any tampering by unqualified personnel will result in immediate forfeiture of the product warranty.

The gas valve assembly and the electronic board are electronically calibrated at the factory during

product testing.

The appliance does NOT need to be adjusted during installation.

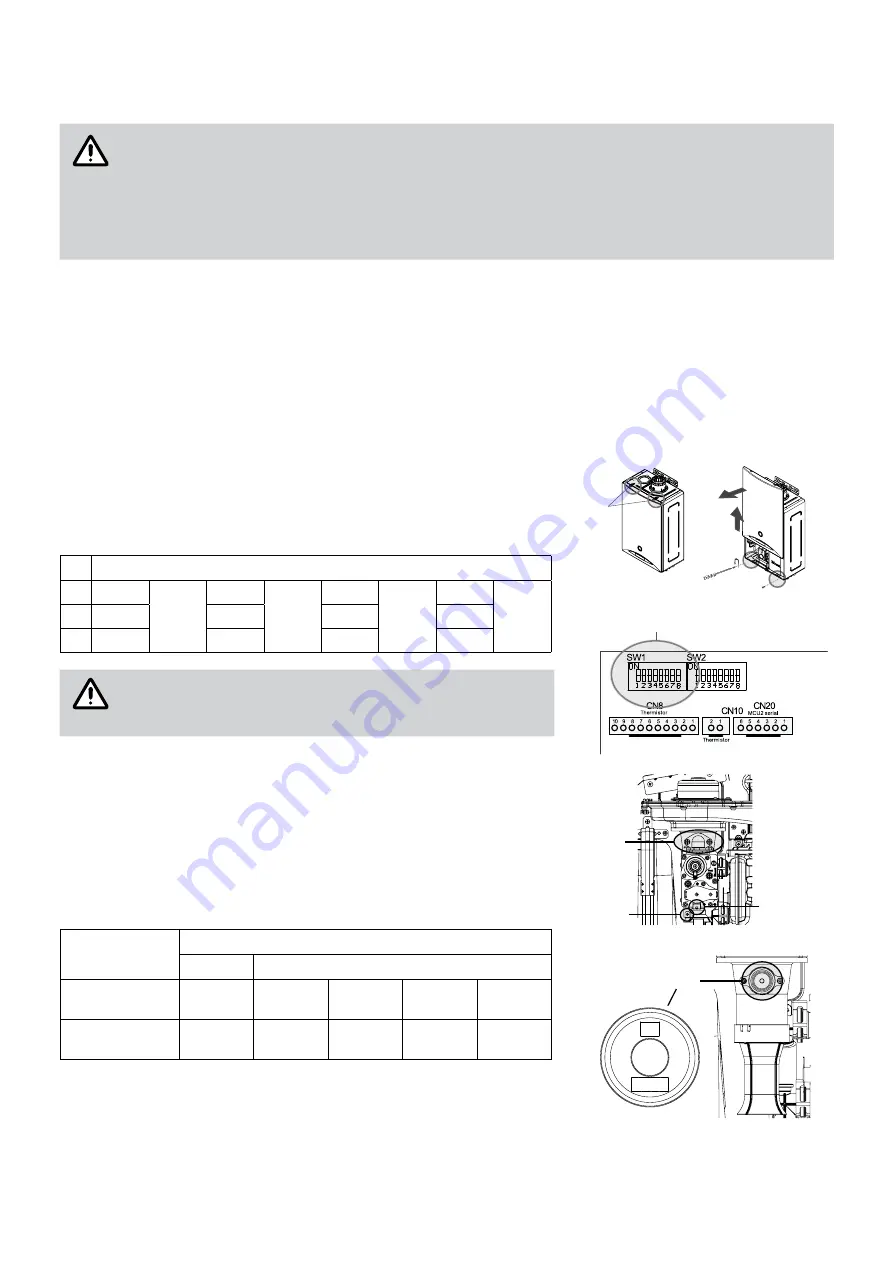

The conversion procedure to a different type of gas consists of three phases:

1.

modification of the microswitches of the electronic board and selection of the new type of gas;

2.

gas nozzle replacement;

3.

verification of CO

2

and possible regulation of gas pressure (at minimum and maximum forced regime).

phase 1

•

Close the gas supply valve and disconnect the plug from the socket;

•

remove the front panel;

•

verify that the type of gas selected by the microswitches of the bank

SW1 coincides with the gas used in the system:

Nr.

SW1

1

OFF

NG

(G20)

ON

Prop.

(G31)

OFF

Air-

prop.

(G230)

ON

LPG

(G30)

2

OFF

OFF

ON

ON

3

OFF

OFF

OFF

OFF

The specific procedure described in PCB paragraph

must be followed, in order to make any change to the

microswitches effective.

phase 2

•

Disconnect the gas valve supply cable;

•

unscrew the screws (3x) that fix the gas valve;

•

remove the valve taking care not to damage the sealing O-rings;

•

replace the gas nozzle:

Model

Letter mark

A

B

REB-KBI2424FF

REB-KBI2929FF

29

G20

G30

G31

G230

REB-KBI3535FF

35

G20

G30

G31

G230

•

assemble the gas valve taking care not to damage the o-rings;

•

open the gas supply valve and check that there are no gas leaks from

the circuit.

ATTENTION

Latches

Main electronic board

Remove the front panel

Dip switches SW1

①

②

ATTENTION

Screw (2x)

Screw

Gas valve

Gas nozzle

Nozzle

Power cable

A

B