Reference Manual Rev 1.13

004R-646-113

Page 1

Table of Contents

1.

INTRODUCTION ...................................................................................................................... 6

1.1.

Overview ....................................................................................................................... 6

1.2.

The Manuals Set ........................................................................................................... 7

1.3.

Document Conventions ................................................................................................. 7

1.4.

Software Comparison K404, K405 and K422 ............................................................... 7

2.

SPECIFICATIONS .................................................................................................................... 8

3.

INSTALLATION ....................................................................................................................... 9

3.1.

Introduction ................................................................................................................... 9

3.2.

General Warnings ......................................................................................................... 9

3.3.

Electrical Safety ............................................................................................................ 9

3.4.

Cleaning ........................................................................................................................ 9

3.5.

Panel Mount Template .................................................................................................. 9

3.6.

Cable Connections ........................................................................................................ 9

3.7.

DC Power (DC PWR + , DC PWR –) .......................................................................... 10

3.8.

Load Cell Connection .................................................................................................. 10

3.8.1.

Load Cell Signals and Scale Build .............................................................. 10

3.8.2.

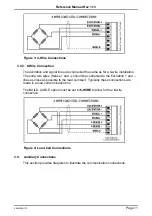

4-Wire Connection ...................................................................................... 10

3.8.3.

6-Wire Connection ...................................................................................... 11

3.9.

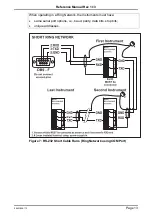

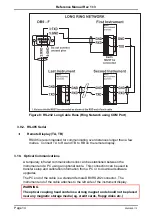

Auxiliary Connections .................................................................................................. 11

3.9.1.

RS-232 Serial .............................................................................................. 12

3.9.2.

RS-485 Serial .............................................................................................. 14

3.10.

Optical Communications ............................................................................................. 14

3.11.

Connecting Shields ..................................................................................................... 15

3.11.1.

Cable Shield Connection and Earthing ....................................................... 16

3.12.

Regulatory Sealing Requirements .............................................................................. 16

3.13.

Accessory Module connection .................................................................................... 17

4.

SETUP MENUS ...................................................................................................................... 18

4.1.

Accessing Setup Menus .............................................................................................. 18

4.1.1.

Setup Display Prompts ............................................................................... 19

4.2.

Exiting Full or Safe Setup ............................................................................................ 19

4.3.

Menu Navigation ......................................................................................................... 19

4.4.

Changing Data ............................................................................................................ 20

4.5.

Numeric Entry ............................................................................................................. 20

4.6.

Selections and Options ............................................................................................... 21

4.7.

Strings ......................................................................................................................... 21

4.7.1.

Normal String Editing .................................................................................. 21

4.7.2.

Numerical String Editing ............................................................................. 22

4.7.3.

ASCII String Editing .................................................................................... 22

4.8.

IP Addresses ............................................................................................................... 22

5.

BASIC OPERATION .............................................................................................................. 23

5.1.

User Interface Display and Controls ........................................................................... 23

5.1.1.

Overview ..................................................................................................... 23

5.1.2.

Display ........................................................................................................ 24

5.1.3.

Primary Annunciators .................................................................................. 24

5.1.4.

Keypad ........................................................................................................ 25

5.2.

Operation Keys ........................................................................................................... 26

5.2.1.

Turn Instrument ON - Short press <Power> ............................................... 26

5.2.2.

Turn Instrument OFF - Long press <Power> .............................................. 26

5.2.3.

Additional Power Information ...................................................................... 26

5.3.

Zero Key ...................................................................................................................... 26

5.4.

Tare Key ...................................................................................................................... 27

5.4.1.

Setting Preset Tare on a Permanent Truck ID ............................................ 27

5.4.2.

Setting Preset Tare on a Temporary Truck ID ............................................ 27

5.4.3.

Gross/Net Key ............................................................................................. 28

5.5.

Truck Key .................................................................................................................... 28

5.5.1.

Truck Key to enter an ID ............................................................................. 28

5.5.2.

Truck Key to select a Truck ID .................................................................... 28