800.545.6566

www.riogrande.com

Sentry Express Digital Temperature Controller

12

Sharing your passion for making jewelry.

Products. Service. Know-how.

©2011 The Bell Group, Inc. All rights reserved.

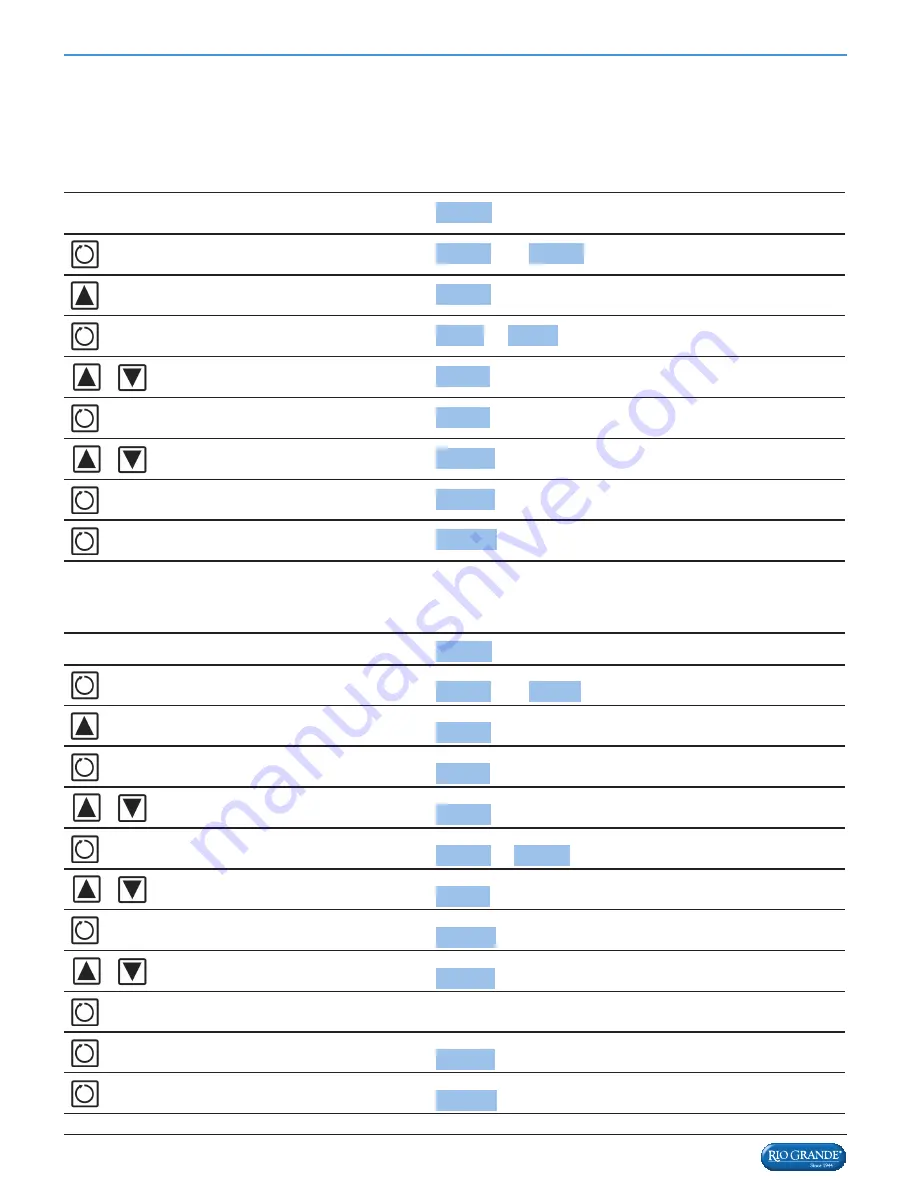

Shorthand Instructions

These instructions may be confusing until you have read more detailed instructions on single Single Segment, page 5, or

Ramp-Hold, page 7. Read the safety guidelines, page 2. After pressing the keys in left column, the center message will appear.

Single Segment

Keys to Press

Display

IdLE

SPd1

thru

PrO4

(Not Down Arrow) Select rate

SPd1

(Sample rate)

°F

or

°C

Enter temperature

1900

(Sample temperature)

HLd

Enter hold time

00.00

(or hold time)

Strt

-O n -

The kiln is now fi ring

Ramp-Hold

Keys to Press

Display

IdLE

SPd1

thru

Pro4

(Not Down Arrow)

Pro1

Select Program #1, 2, 3, or 4

rA 1

Enter Segment 1 rate

500

(Sample rate)

°F 1

or

°C 1

Enter temperature

1900

(Sample temperature)

HLd 1

Enter hold time

00.00

(or hold time)

First segment not needed: enter a rate of 0000.

Strt

-O n -

The kiln is now fi ring