东方日升新能源股份有限公司

PV module installation and

maintenance manual

RISEN ENERGY CO.,LTD.

主导部门:组件研发中心

Page:NO.5 ,Total 41

CATALOGUE

Unloading, Transportation and Storage

................................................................................................ 12

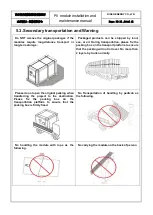

Secondary transportation and Warning

......................................................................................... 14

Matters needing attention for unpacking

............................................................................................. 16

Environment conditions and site selection

.................................................................................. 17

Installation requirements for bifacial module

.............................................................................. 19

Bolting method for framed Bi-facial dual glass module

............................................................ 22

8.1.3 Offshore PV module connector protection device

......................................................................... 23

Installation method of fixed support

............................................................................................... 25

12.2.Module visual inspection and replacement

....................................................................................... 38