1-4

Perfect Binder User’s Guide

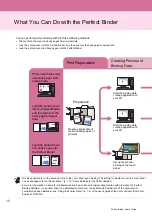

Using the Printer Driver

This section describes how to allocate original data

as the cover and the body pages when sending a

binding job and the setting items of the screen of

the printer driver.

Set the printer configuration when using the printer

driver for the first time or when adding optional

equipment to the printer.

1

Display the [Environment] tab.

The [Environment] tab is displayed when the printer

being used is right clicked from [Devices and

Printers] under the [Start] menu and [Printer

Properties] is opened.

2

Click [Get Printer Info].

Automatically acquires the information of optional

configuration from the printer. The information

acquired from this unit is displayed on [Printer

Configuration].

3

Click [Custom Paper Entry].

You can register up to 99 items worth of irregular

size paper. For more information on the registration

method of paper size, see the guides of the

ComColor GD Series printer.

The original data is divided into cover sheets and

body pages and printed. The page allocation will

vary depending on the setting of [Duplex Print] for

the cover sheet. Prepare the original data suitable

for the cover type.

The first two pages of the original data are

allocated on the front and back cover sheets. The

subsequent pages are allocated on the body

pages.

The first page of the original data is allocated on the

cover sheet. The subsequent pages are allocated

on the body pages.

• The displayed setting items vary depending on

the selected items or settings made by the

administrator.

• If the optional equipment necessary for the

setting is not attached, the setting item is not

displayed.

• Before performing perfect binding, configure the

printer driver settings on your computer.

• To perform variable data printing, use mail

merge available with Microsoft Word.

Setting the Printer

Configuration

• To set the printer configuration manually,

select [Finisher:] - [ON (Perfect Binder)].

Allocating the Original

Data to the Cover Sheet

and Body Pages

Performing Duplex Printing on

the Cover Sheet

Performing Simplex Printing on

the Cover Sheet (blank inside

covers)

Outside cover

(Cover 1,

Cover 4)

Inside cover

(Cover 2,

Cover 3)

Body page

Outside cover

(Cover 1,

Cover 4)

Body page

Summary of Contents for Perfect Binder G10 120

Page 1: ...User s Guide Series 061 36009 ...

Page 28: ...26 Perfect Binder User s Guide ...

Page 76: ...3 20 Chapter 3 Appendix Perfect Binder User s Guide 061 36009 107 ...

Page 77: ......