Troubleshooting

Troubleshooting Tips

94

The left and right print positions have

been shifted.

The left and right print positions have

not been adjusted for the center.

The Paper Feed Tray is equipped

with the Horizontal Print Position

Adjustment Dial. Lower the tray,

adjust the position, and then perform

proof copy to check the

position.

)

p.46

Paper sticks to the surface of the

Print Cylinder(Drum).

(The

indicator blinks frequently.)

The margin at the top of the original

or print is too small.

The margin of the original (top of the

print in the paper output direction)

must be

3

/

16

"(5 mm) at least. Lower

the vertical print position. If this

adjustment is impossible, reproduce

an original with enough margin and

perform the master-making

operation again.

The print paper is inappropriate.

Use the recommended paper.

The original has a solid black portion

at its top.

If an original has a solid black portion

at the top, printed copies may not

properly output. Replace the original

in the reverse direction and restart

the master-making process.

Printed and curled copies are output. The print paper is loaded at a

horizontal grain direction.

Load print paper with a vertical grain

direction.

Printed copies are not neatly aligned

in the Paper Receiving Tray.

(The

indicator blinks frequently.)

The positions of the Receiving Tray

Paper Guides and the Paper

Stopper are inappropriate.

Adjust the Receiving Tray Paper

Guides and the Paper Stopper to the

size of paper. For thick paper,

slightly widen them as necessary.

If you have adjusted the horizontal

position on the Paper Feed Tray,

shift the Receiving Tray Paper

Guides in the same direction.

)

p.21

The positions of the Paper Jumping

Wings are inappropriate. (For

RZ2XX, unavailable)

Position the Paper Jumping Wings

according to the size and thickness

of paper.

)

p.21

The Paper Arrangers are not

properly set. (For RZ2XX,

unavailable)

Set the Paper Arrangers properly.

)

p.21

The corrugators are not properly set.

(For RZ3XX, unavailable)

Set the corrugators properly.

)

p.21

Problem

Cause

Action

Troubleshooting

Troubleshooting Tips

95

Paper is not smoothly fed from the

Paper Feed Tray. (No paper is fed.)

The position of the Paper Feed

Pressure Adjustment Lever was

inappropriate.

For thick or smooth-surface paper,

set the Paper Feed Pressure

Adjustment Lever to “CARD”.

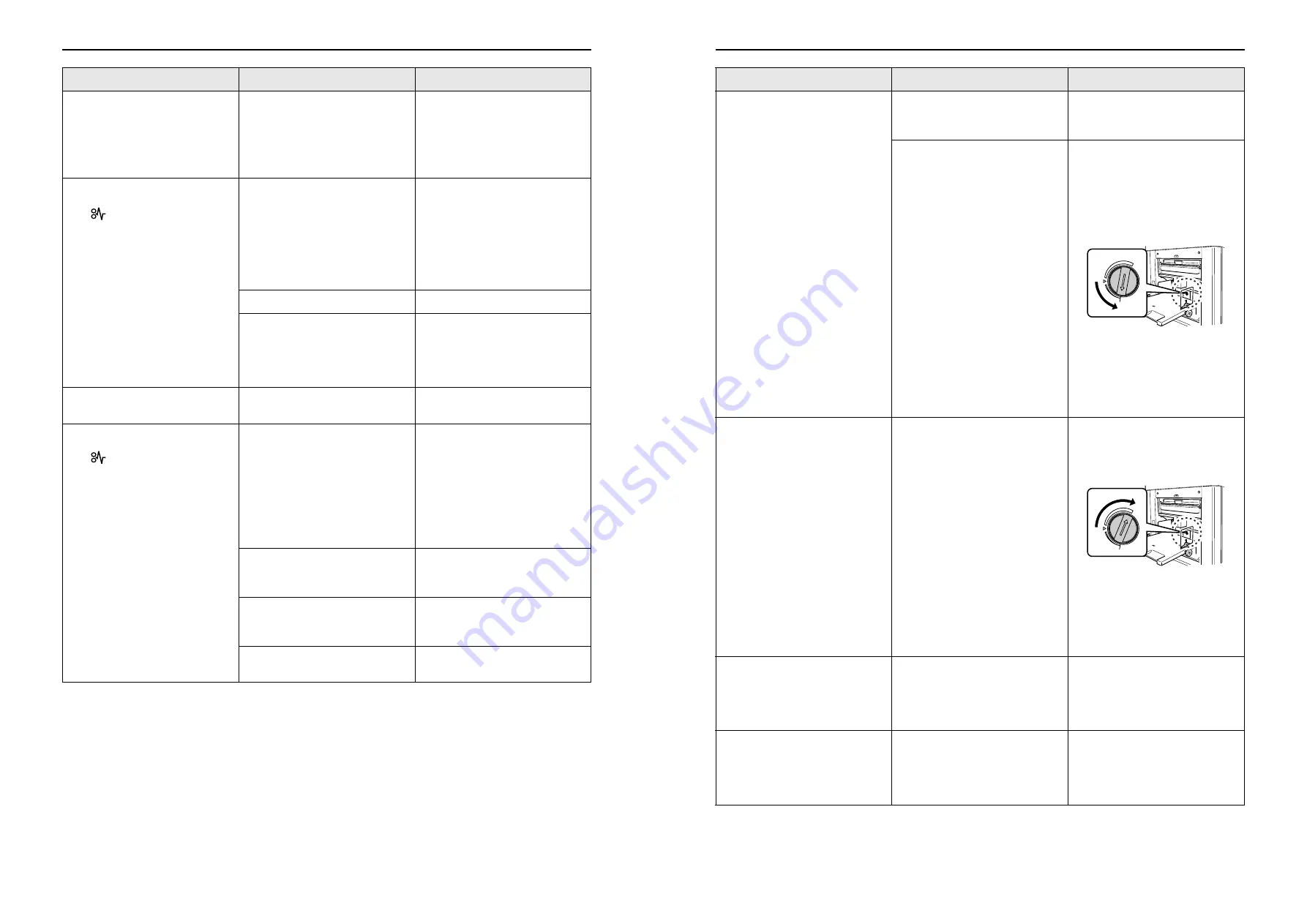

The angle of the Stripper Plate is

inappropriate.

If the above adjustment does not

solve the problem, use the following

procedure:

Turn the Stripper Plate Angle

Adjustment Dial in the arrow

direction to adjust the angle of the

Stripper Plate.

Important!:

• Before performing the adjustment,

always remove paper from the

Paper Feed Tray and check that

the tray has been lowered to the

bottom.

Paper is not smoothly fed from the

Paper Feed Tray. (Piled paper is

feed)

The angle of the Stripper Plate is

inappropriate.

Turn the Stripper Plate Angle

Adjustment Dial in the arrow

direction to adjust the angle of the

Stripper Plate.

Important!:

• Before performing the adjustment,

always remove paper from the

Paper Feed Tray and check that

the tray has been lowered to the

bottom.

Paper frequently jams in the paper

feed section even when the Paper

Feed Pressure Adjustment Lever is

set to “CARD”.

The angle of the Stripper Plate is

inappropriate.

Refer to the procedure provided for

“Paper is not smoothly fed from the

Paper Feed Tray. (No paper is fed.)”,

and adjust the angle of the Stripper

Plate.

The back of printed cards is peeling

or the leading edge of the printed

cards is wrinkled.

The angle of the Stripper Plate is

inappropriate.

Refer to the procedure provided for

“Paper is not smoothly fed from the

Paper Feed Tray. (No paper is fed.)”,

and adjust the angle of the Stripper

Plate.

Problem

Cause

Action

Riso Kagaku Technical Training Center Version