GENISYS AL-900

Dock Leveler Owner’s Manual

14

Publication:

AMEN00044 2017-01-27

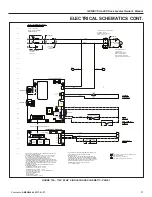

LED STATUS CHARTS

PIT DOCK LEVELER

RITE-HITE PRODUCTS CORP.

STANDALONE CONTROLS

PUSH

BUTTONS

12VDC

AR

TD

IN

PUT

COM

BINE

D POW

ER

UNI

T

IN

PU

T

[CM

BD P

U]

GREEN

LI

GHT TO OPERATE

LEVE

LER INPUT [G

LT

IT

L]

[SEE DIP SWI

TCH #2

]

OVERHEA

D

DOOR OPEN I

NTER

LOCK INPUT [OH

D

IT

L]

[SEE DIP SWI

TCH #3

]

RA

IS

E P

USH

B

UTTO

N

MOTOR CONTACTOR OUTPUT [LVLR CONTR]

12

VD

C

POW

ER SU

PP

LY

O

K

LE

VE

LE

R

SO

LEN

OI

D

#1

-

LI

P

O

UT

(K

1)

[S

TA

NDARD]

LE

VE

LE

R

SO

LEN

OI

D

#1

-

LI

P

O

UT

(K

1)

[E

-S

TOP

EQ

UI

PP

ED

]

AUX

BOARD POWER SUPP

LY

O

K

TERMINAL BLOCK NO.

J9.2

J11.2

J11.1

J9.1

J16.4

J10.3

J10.1-2

J2.3

J2.3

-

LEVELER CONTROL BOARD LEDs

LD5

LD3

LD2

LD4

LD14

LD6

LD1

-

-

-

LEVELER AUX BOARD LEDs

-

-

-

-

-

-

-

LD1

LD1

LD4

02.01.00 REST STATE

F

F

?

?

-

F

T

F

T

T

02.01.01 RAISE SEQUENCE

F

F

ITL

ITL

M

T

T

F

T

T

02.01.02 AUTOMATIC RETURN TO DOCK

T

F

ITL

ITL

-

T

T

F

T

T

02.01.03 COMBINED POWER UNIT SEQ

F

T

?

?

-

T

T

F

T

T

02.05.00 RUN FAULT STATE

?

?

?

?

?

F

T

?

?

T

NO.

STATE / SEQUENCE NO.

INPUTS

LEVELER CONTROL BOARD

OUTPUTS

LEVELER AUX BOARD

OUTPUTS

Y

A

L

E

R

C

D

V

2

1

D

L

E

I

F

PIT DOCK LEVELER

S

T

U

P

T

U

O

.

P

R

O

C

S

T

C

U

D

O

R

P

E

T

I

H

-

E

T

I

R

DOK-COMMANDER CONTROLS

PUSH

BUTTONS

C

D

V

2

1

C

D

V

2

1

C

D

V

2

1

AR

TD

IN

PUT

OVERHEAD DOOR OPEN INTER

LOCK

INPUT [OHD ITL]

LE

VE

LE

R

ST

O

RE

D

INTE

RL

O

CK

T

O

U

NL

O

CK

*

[UNLK ITL]

RA

IS

E P

USH

B

UTTO

N

MOTOR CONTACTOR OUTPUT [LVLR CONTR]

12

VD

C

POW

ER SU

PP

LY

O

K

LE

VE

LE

R

SO

LEN

OI

D

#1

-

LI

P

O

UT

(K

1)

[S

TA

NDARD]

LE

VE

LE

R

SO

LEN

OI

D

#1

-

LI

P

O

UT

(K

1)

[E

=S

TOP

EQU

IPP

ED

]

AUX

BOARD POWER SUPP

LY

O

K

TERMINAL BLOCK NO.

J14.4

J14.2

J14.3 MEMBRANE

J15.1

J2.1-6

J7.3

J7.3

-

MICRO CONTROL BOARD LEDs

LD32

LD29

LD30

LD52

LD42

LD7

-

-

-

LEVELER AUX BOARD LEDs

-

-

-

-

-

-

LD10

LD10

LD4

02.01.00 REST STATE

F

?

?

-

F

T

F

T

T

02.01.01 RAISE SEQUENCE

F

ITL

?

M

T

T

F

T

T

02.01.02 AUTOMATIC RETURN TO DOCK

T

ITL

?

-

T

T

F

T

T

02.01.03 COMBINED POWER UNIT SEQ

F

?

?

-

T

T

F

T

T

02.05.00 RUN FAULT STATE

?

?

?

?

F

T

?

?

T

NO.

STATE / SEQUENCE NO.

KEY

? - VARYS DEPENDING ON OPERATION

M - LIGHTS WHEN BUTTON PRESSED

S

E

H

C

T

I

W

S

P

I

D

G

N

I

S

U

Y

D

A

E

T

S

O

T

T

E

S

[

G

N

I

H

S

A

L

F

/

G

N

I

S

L

U

P

-

P

F

F

O

-

F

]

N

O

Y

D

A

E

T

S

-

T

N

O

T

U

P

N

I

K

C

O

L

R

E

T

N

I

-

L

T

I

RUN FAULT STATE

If Leveler Motor is operated continuously for 60 seconds, syste

m will enter RUN FAULT STATE.

After a 60 second rest period, system will automatically enter the REST STATE and resume normal operation

.

OUTPUTS

RELAY

FIELD

INPUTS

MICRO CONTROL BOARD

POWER

BOARD

LEVELER AUX BOARD