GENISYS AL-900 Dock Leveler Owner’s Manual

Publication:

AMEN00044 2017-01-27

17

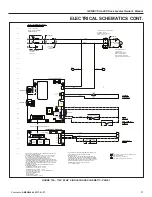

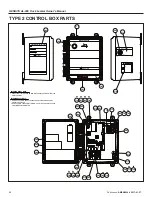

ELECTRICAL SCHEMATICS CONT.

(COM)

(LSOL1/J23)

(N)

LIP-OUT LSOL1

CIRCUIT

G

120VAC, 0.3 AMPS

7(BK)

X2(WH)

"LIP OUT" SOLENOID (SOL1)

(ARTD/J92)

(COM)

ARTD

CIRCUIT

ARTD LIMIT SWITCH (LS2)

N.O.

4(BK)

12(WH)

G

(ARTD/J92)

LEGEND:

DENOTES WIRE CONNECTIONS THRU TERMINAL BLOCK.

DENOTES FIELD WIRES.

DENOTES WIRE NUT CONNECTION.

DENOTES MALE/FEMALE PLUG CONNECTOR.

LEVELER POWER CB

J11

1

1

JP1

1

JP2

1

J2

TERM1

SP1

DIAG

U14

SW1

J4

J1

J3

1

RESET

J10

J8

+12VDC

LD7

LD9

J6

LD14

LD8

LOWER

E-STOP

LIP OUT

RAISE

1

1

LVLR CONTACTOR (J10-3)

OHD ITL (J9-1)

ARTD (J9-2)

GLT ITL (J11-1)

CMBD PU (J11-2)

FH1

HIGH

VOL

TA

GE

U3

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

POWER SUPPLY

10FU1

108

N(WH)

1L1(BK)

108

(RIBBON CABLE TO LVLR AUX)

LD13

LD12

LD11

LD6

LD1

LD3

LD2

LD5

LD4

7. LS1 PROVIDED BY OTHER FOR OVERHEAD DOOR INTERLOCK (OPEN).

LS2 PROVIDED BY RITE-HITE WITH LEVELER FOR ARTD.

8. DISCONNECT NOTES:

-FUSED DISCONNECT IS NOT PROVIDED BY RITE-HITE PRODUCTS

CORPORATION. DISCONNECT MUST BE PROVIDED BY OTHERS AND

INSTALLED PER LATEST EDITION OF UL508A AND NEC REQUIREMENTS.

-A BRANCH CIRCUIT DISCONNECT SHALL BE LOCATED WITHIN A 50 FT.

RADUIS AND BE VISIBLE FROM THE CONTROL BOX LOCATION.

[REFERENCE LATEST EDITION OF NEC, SECTION 430]

9. CLASS 1 CONTROL CIRCUIT.

DOOR OPEN ITL (LS1)

N.O.

(OHD ITL/J91)

OHD OPEN ITL

CIRCUIT

SPARE (J10-4)

X1/L1

X2/N

12VDC

12VDC

COM

COM

μSD

FROM CUSTOMER MAIN POWER &

SAFETY PROTECTION DEVICE.

110-120v. 1PH. 60HZ.

USE 30.0A DUAL ELEMENT

TIME DELAY FUSES

1L1(BK)

N(WH)

K3

K2

K1

LD2

LD3

LD4

LD1

J1

J2

12VDC

LSOL1

LIP OUT

LSOL2

LOWER

LSOL3

LSOL2 (J2-2)

LSOL3 (J2-1)

LSOL1

(J2-3)

LEVELER OPTION BOARD

F1

(RIBBON CABLE FROM LEVELER POWER CB)

LSOL3

LSOL2

LSOL1

X2/N

X2/N

X1/L1

LVLR SOLENOID

20FU1

OVERLOAD PROTECTION PROVIDED

BY THERMAL SWITCH

[REFERENCE LATEST EDITION

OF NEC, SECTION 430]

1L1(BK)

N(WH)

(COM)

SEE DETAIL 'B'

SEE DETAIL 'C'

(COM)

SEE DETAIL 'A'

COM

1 2 3

1. INSTALL PER LOCAL ELECTRICAL CODES. REFER ALL INSTALLATION AND

SERVICE TO QUALIFIED PERSONNEL.

2. ALL INCOMING POWER (FROM DISCONNECT TO CONTROL BOX) AND

MOTOR FIELD WIRING TO BE MINIMUM #10/12GA. 60°/75°C COPPER

WIRE, INSULATED SUFFICIENTLY FOR INCOMING VOLTAGE.

3. ALL CONTROL FIELD WIRING TO BE MINIMUM #14GA. 60°/75°C

COPPER WIRE ONLY, INSULATED SUFFICIENTLY FOR INCOMING VOLTAGE.

4. ALL INTERNAL WIRING TO BE #14GA. MINIMUM FOR POWER CIRCUITS AND

CIRCUIT BOARD POWER, #16GA MINIMUM FOR CONTROL CIRCUITS, 90°C,

RED COPPER WIRE UNLESS OTHERWISE NOTED, INSULATED SUFFICIENTLY

FOR INCOMING VOLTAGE.

5. SEE OWNERS MANUAL FOR COMPLETE OPERATING INSTRUCTIONS.

6. TORQUE REQUIREMENTS:

-PCB TERMINAL BLOCK POWER (J3/J5): 7.0 LB-IN

-PCB TERMINAL BLOCK CONTROL (J7): 6.0 LB-IN

-PCB TERMINAL BLOCK ALL OTHER: 4.0 LB-IN

-INCOMING POWER TERMINAL BLOCK: 12.2-13.4 LB-IN (MIN-MAX)

-FUSE BLOCK POWER: 14.75 LB-IN

-CONTACTOR/OVERLOAD: 15 LB-IN

-DISCONNECT: 7 LB-IN

-GROUND TERMINAL: 35 LB-IN

-SOLID STATE RELAY TERMINAL: 35 LB-IN

1MCR

(A2) (A1)

12VDC, 2W

J103(BL)

12V(BL)

12V(BL)

LEVELER

CONTROLS

121

N(WH)

121

1L1(BK)

T1

T2

T3

L1

L2

L3

1MCR

T1

T2

T3

L1

L2

L3

SEE NOTE 2

G

T1

M

T2

J8-2

J8-1

J10-4

J10-3

J10-2

J10-1

J9-2

J9-1

J11-3

J11-2

J11-1

J11-5

J11-4

J2-6

J2-5

J2-4

J2-3

J2-2

J2-1

SEE NOTE 2

FUSED DISCONNECT

(BY OTHERS)

90°C, BLACK,

COPPER WIRE

SEE NOTE 8

L1

N

G

1FU1

DUMMY

1L1

N

1L1

N

#10GA. MIN.,

THERMAL SWITCH

(IN MOTOR)

(N)

(N)

LEVELER MOTOR (BASE)

115v. 1PH. 60Hz.

(THERMALLY PROTECTED

WITH AUTOMATIC RESET)

REFER TO MOTOR CONNECTION

DETAIL PAGE FOR CONNECTION/FLA

FIGURE 15A - 115V. 60 HZ. SINGLE PHASE SCHEMATIC - PAGE 1