18

Pub. 1147 - Rev. 7 SEPTEMBER 2004

Mechanical Dock Leveler Hydraulic Conversion

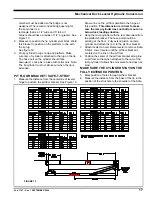

T-Strut base (Dim "L"). See Figure 9.

7. On the Safe-T-Strut, measure the distance from the

top of the collar to the distance you measured on the

leveler. Subtract 2 inches from this measurement

and draw a line at this position on the strut.

See Figure 9.

8. Cut the Safe-T-Strut at the line.

9. Slide the drill template that is provided onto the cut

end of the Safe-T-Strut. Clamp the template in place

when the edge is flush with the end of the strut.

10. Drill a 1/4" dia. pilot hole through the strut. Remove

the template and enlarge the hole using a 5/8"

diameter drill.

11. Using the hoist, raise the leveler and install the Safe-

T-Strut.

12. Drill holes in concrete pit floor. Fasten the pit floor

bracket securely using (6) 5/8" diameter bolts that

are a minimum of 4" long.

13. Insert clevis pin through pit floor bracket. Lock pins

in place with cotter pins.

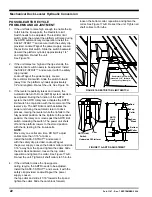

ANCHORING REAR OF LEVELER

Securely anchor the rear frame of the

leveler in a minimum of (2) locations to the pit floor

or rear pit wall. This is done to eliminate any frame

movement when the deck is being raised. Use 5/8”

diameter anchors that are a minimum of 4” long.

TOE GUARD INSTALLATION

1. Install toe guards to leveler. Insure no binding will

occur during leveler operation. Be sure to also check

for interference on a below dock loading situation.

PUMP/HOSES INSTALLATION (STANDARD)

1. Install pump assembly under leveler in a position

that is easy to access for maintenance, yet clear

from impact when the leveler is bottomed out below

dock. Weld support bracket to frame.

2. Install 90

o

elbows in pump and cylinders.

3. Turn adapter onto 90

o

elbow of ramp cylinder. Fasten

securely.

4. Install velocity fuse into adapter of ramp cylinder.

Fasten securely.

5. Install hoses between the pump and the ramp and

lip cylinders. The small hose should be connected to

the lip cylinder and the larger hose should get

fastened the velocity fuse on the ramp cylinder.

6

Install breather on ramp cylinder.

7. Fill oil reservoir to level indicated on tank. Use MIL-

H-5606 oil.

PUMP/HOSES INSTALLATION (REMOTE

PIT)

1. Install pump assembly in the remote location. Insure

that the hose length provided will be sufficient to

reach both hydraulic cylinders during the full range

of leveler motion.

2. Install 90

o

elbows in pump and cylinders.

3. Turn adapter onto 90

o

elbow of ramp cylinder. Fasten

securely.

4. Install velocity fuse into adapter of ramp cylinder.

Fasten securely.

5. Install hoses between the pump and the ramp and

lip cylinders. The small hose should be connected to

the lip cylinder and the larger hose should get

fastened the velocity fuse on the ramp cylinder.

6. Install breathers in cylinders.

7. Fill oil reservoir to level indicated on tank. Use MIL-

H-5606 oil.

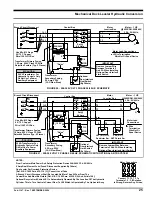

INSTALLATION OF OPTIONAL ARTD

SYSTEM

1. Slide ARTD subassembly over the lip cylinder and

pin the subassembly in place using the rear cylinder

pin on the lip cylinder.

2. Using hose clamp provided, fasten front of ARTD

assembly securely to the front of the lip cylinder at

the 1” spacer on the bracket.

3. Locate bolt and washer that will secure slide rod and

apply lok-tight to the threads. Securely tighten bolt

through slide rod into front lip cylinder hinge pin. See

Figures 17A & B and parts list in back of manual.

4. Route wiring from switch back to motor junction box.

Fasten securely to stringers.

5. Weld restrictor limit switch bracket to center stringer

3” forward from center of ramp cylinder pin. If

necessary, it is acceptable to mount the switch plate

to the ramp bracket. See figure 16.

6. Install restrictor limit switch.

7. Wire per schematics on Figures 18-27.

FIGURE 13