6 Installation

EN

34

Rittal Liquid Cooling Package

Notes on water quality

For safe operation, it is vital that the VBG guidelines on

cooling water are observed (VGB R 455P). Cooling

water must not contain any limescale deposits or

loose debris, and it should have a low level of hard-

ness, particularly a low level of carbonate hardness.

The carbonate hardness should not be too high, par-

ticularly for recooling within the plant. On the other

hand, however, the water should not be so soft that it

attacks the operating materials. When recooling the

cooling water, the evaporation of large quantities of

water must not lead to excessively high salt contents,

since electrical conductivity increases as the concen-

tration of dissolved substances rises, and the water

thereby becomes more corrosive. For this reason, not

only is it always necessary to add a corresponding

quantity of fresh water, but also to remove part of the

enriched water. Water with high gypsum content is un-

suitable for cooling purposes because it has a ten-

dency to form boiler scale that is particularly difficult

to remove. Furthermore, cooling water should be free

from iron and manganese, because deposits may oc-

cur which settle in the pipes and block them. At best,

organic substances should only be present in small

quantities, because otherwise sludge deposits and

microbiological contamination may occur.

6.1.3

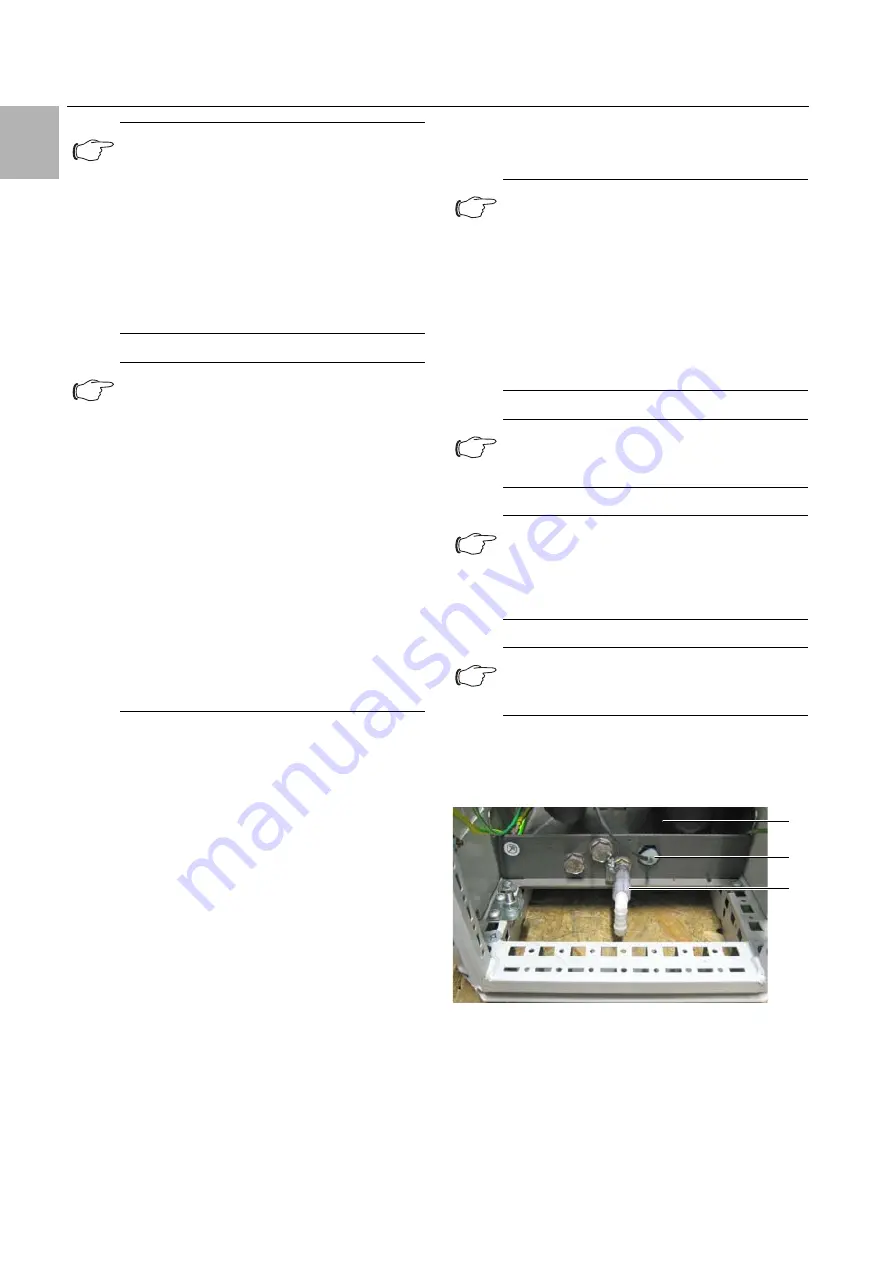

Connecting the condensate discharge

Any condensate which may develop is collected in the

condensate collecting tray (fig. 46, item 1) in the water

module of the Liquid Cooling Package.

Fig. 46:

Condensate discharge

Key

1

Condensate collecting tray

2

Leakage sensor

3

Condensate discharge

The Liquid Cooling Package is additionally equipped

with a condensate discharge (fig. 46, item 3) via

Note:

Immediately after connecting the water cir-

cuit, the flow rate may be monitored by fitting

the device with an optional display with

touch function. To do this, first check wheth-

er the control valve is completely open (see

section 9.2.3 "Operation in stand-alone

mode"). If the control valve is closed or only

partially open, it can be opened in manual

mode via the web interface (see section

9.5.4 "Config").

Note:

The pipework in the building should be de-

signed according to the Tichelmann Princi-

ple in order to maintain a hydraulically

balanced system.

If this is not the case, the flow volume of each

Liquid Cooling Package must be assured by

using a flow quantity regulator.

Ideally, the Liquid Cooling Package is con-

nected to the cooling water system using a

water/water heat exchanger.

Pros:

– Reduction of water volumes in the second-

ary circuit,

– Setting of a defined water quality,

– Setting of a defined input temperature and

– Setting of a defined volumetric flow.

Note:

The Liquid Cooling Package is secured

against excess pressure as regards a maxi-

mum permissible pressure (PS) of 6 bar if no

cooling medium liquid is trapped. If shut-off

valves that could cause cooling medium

liquid to become trapped are installed on

site, pressure relief vessels with safety

valves (6 bar blow-off pressure) must be

built into the coolant circuit of the recooling

system.

Note:

Before commencing operation with water, all

supply lines must be adequately flushed.

Note:

To avoid the loss of fluids due to diffusion

(open and closed systems) or evaporation

(open systems), the use of automatic filling is

advisable.

Note:

The 2-way control valve used in the device is

opened at zero current.

3

1

2