3 Device description

EN

12

Rittal Liquid Cooling Package

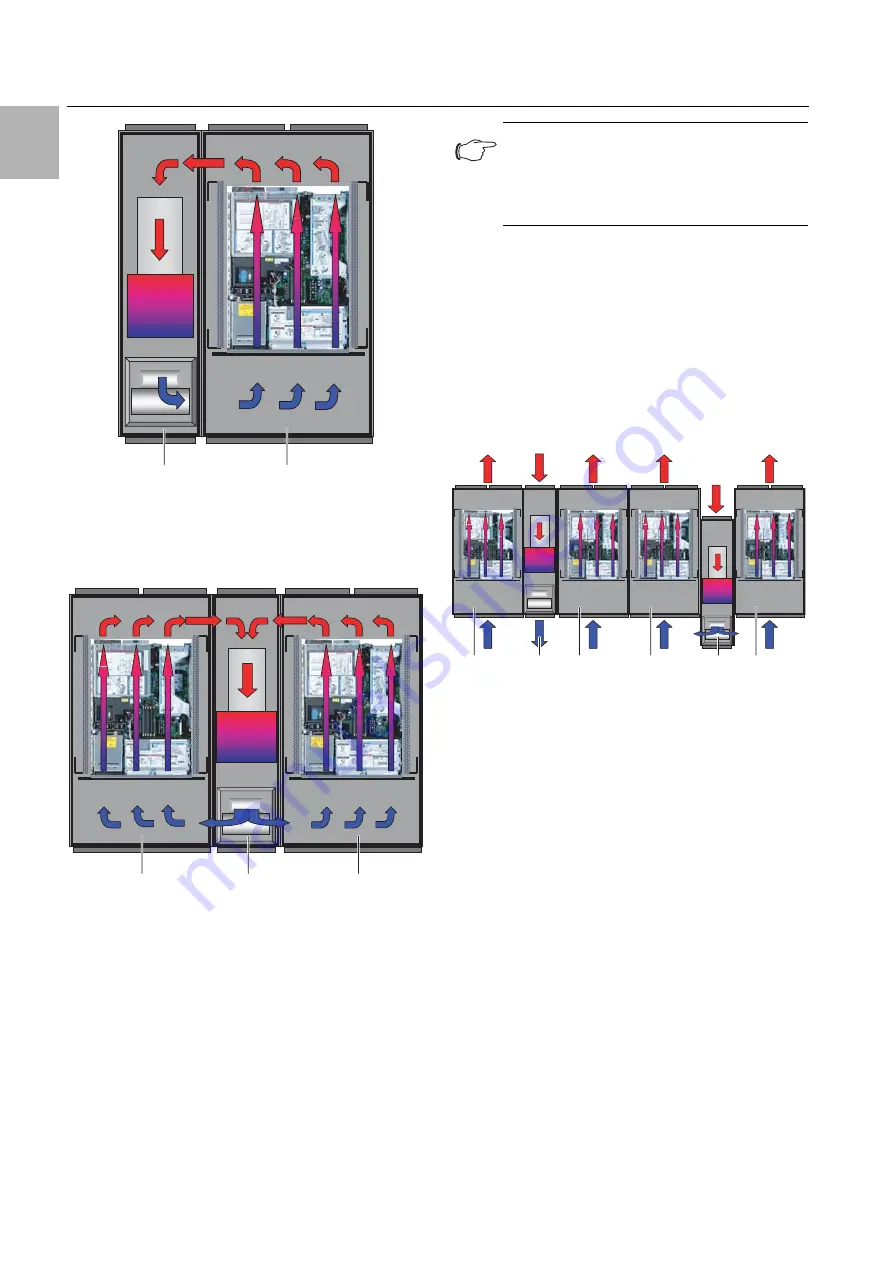

Fig. 7:

Air routing with a bayed server enclosure – top view

Key

1

LCP Rack

2

Server enclosure

Fig. 8:

Air routing with two bayed server enclosures – top

view

Key

1

Server enclosure

2

LCP Rack

The system consisting of the LCP Rack and the server

enclosure should be sealed as effectively as possible

in order to prevent the loss of cooling air. To accom-

plish this, the enclosure is equipped with side panels,

roof and gland plates. Any existing cable entries

should be sealed e.g. using suitable brush strips.

Whilst the system is in operation, both the front and the

rear doors should be kept completely shut.

3.2.3

LCP Inline and LCP Inline flush

Targeted air routing by hot air extraction from the hot

aisle and cold air blown into the cold aisle has a fun-

damental effect on the amount of heat to be dissipat-

ed.

In order to achieve sufficient cooling in the server en-

closure, it is important to ensure that the cooling air

passes through the interior of the built-in units and is

unable to flow past at the sides.

Fig. 9:

Air routing with bayed server enclosures – top view

Key

1

LCP Inline

2

Server enclosure

3

LCP Inline flush

For this purpose, the system consisting of LCP Inline

or LCP Inline flush, server enclosure and cold aisle

containment should be sealed as effectively as possi-

ble in order to avoid a decrease in cooling capacity

due to mixing of cold and hot air. This is achieved by

sealing the cold aisle with doors at the beginning and

end of the rack rows, and sealed against the ceiling

with roof elements. Existing cable entry glands are ad-

ditionally sealed e.g. with suitable brush strips.

2

1

2

1

1

Note:

However, the system does not need to be

completely airtight, thanks to the high, coor-

dinated air throughputs of the server and

LCP fans.

2

1

3

2

2

2