17 Preparation and maintenance of the cooling medium

EN

86

Rittal Liquid Cooling Package

17

Preparation and maintenance of

the cooling medium

Depending on the type of installation to be cooled,

certain purity requirements are placed on the cooling

water in a recooling system. According to the level of

contamination and the size and design of the recool-

ing systems, a suitable process is used to prepare

and/or maintain the water. The most common types of

contamination and frequently used techniques to

eliminate them in industrial cooling are:

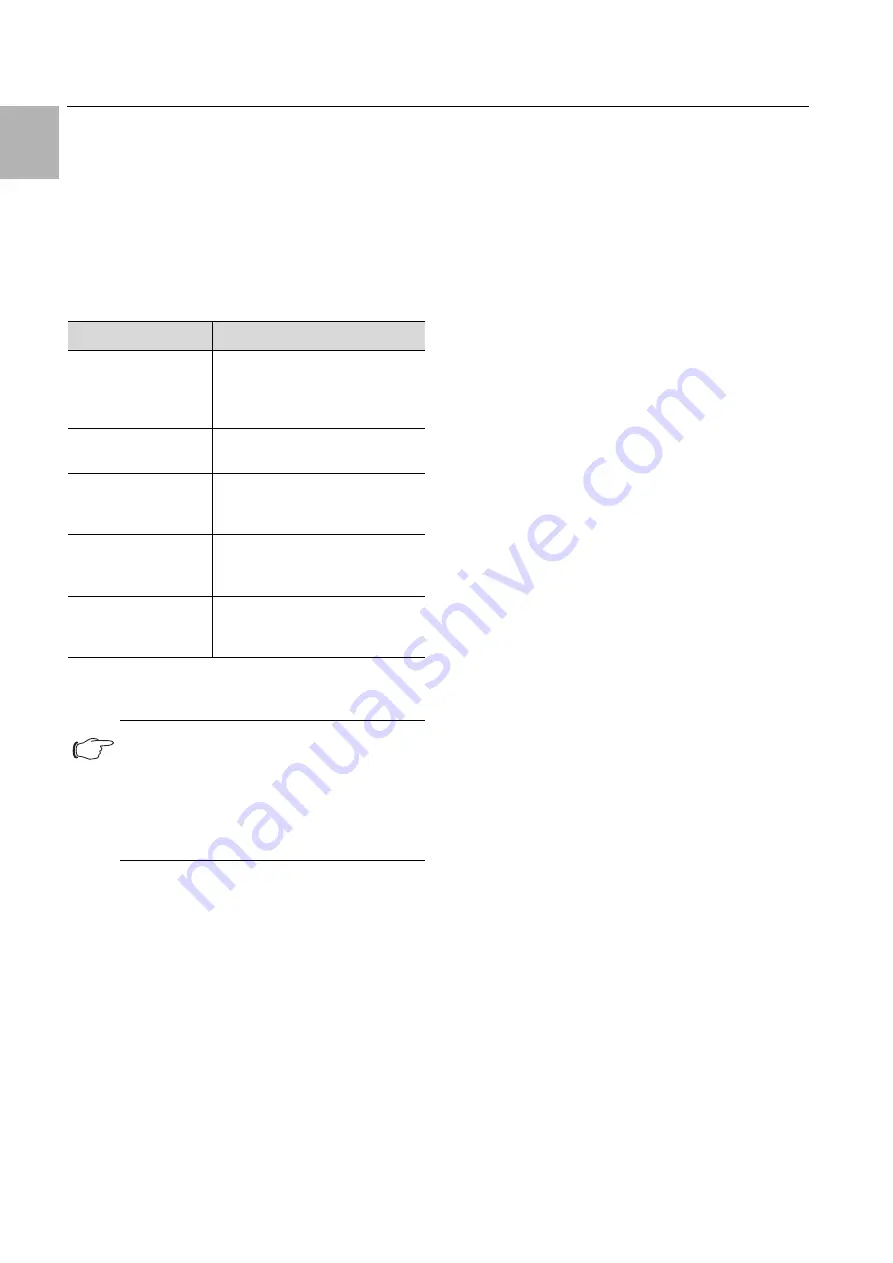

Tab. 42: Cooling water contaminants and treatment

procedures

Type of impurity

Procedure

Mechanical contami-

nation

Filter the water using:

Mesh filter, sand filter, cartridge

filter, precoated filter, magnetic

filter

Excessive hardness

Soften the water via ion ex-

change

Moderate content of

mechanical contami-

nants and hardeners

Treat the water with stabilisers

and/or dispersing agents

Moderate content of

chemical contami-

nants

Treat the water with passivators

and/or inhibitors

Biological contami-

nants, slime bacteria

and algae

Treat the water with biocides

Note:

For the proper operation of a recooling sys-

tem that uses water on at least one side, the

composition of any additive used or system

water should not deviate substantially from

hydrological data presented in section 16.1

"Hydrological information".