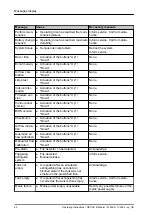

11.2.1

Checking for proper installation

Check whether the system is installed in the upper third.

Check and report horizontal installation using a spirit level.

11.2.2

Checking for external damage

Check the pipe system, the connections and the system itself for external damage.

11.2.3

Recording the WA No. / Part No. / F. No.

Read the factory order number (WA No.), the part number (Part No.) and the pro-

duction number (F. No.) of the system on the labels and report them in the service

report. The labels are on the housing cover and on the rear of the system.

11.2.4

Recording the date of the current maintenance / inspection

Fill out the report for the date of the current and last maintenance by hand or read it

out via the Maintenance Program

Chapter 10.6 “Customer data” on page 95

.

11.2.5

Recording the current version

Refer to the control menu for the current version states

.

● Firmware version

● Control panel version

● BIOS version

Record the different versions in the service report and compare with the old data. A

deviation is to be noted with an explanation.

11.2.6

Checking and recalibrating the air flow measured values

Refer to the control menu for the current measured values and report them

Chapter 8.6 “Air flow calibration” on page 73

.

The following measures are required in the event of a deviation from the old values

(a tolerance of ±10 % is permissible):

● Check the pipe system for contamination.

● Check the pipe system for leaks.

● Check that the holes in the pipe system are aligned correctly.

After correcting the fault, recalibrate the air flow and compare with the old values

Chapter 8.6 “Air flow calibration” on page 73

.

Maintenance

Operating Instructions / DET-AC III Master / 916005 / 11-2022 / en_US

104