7 Maintaining the machine

18

We reserve the right to make technical modifications.

Rittal electrical crimping machine R8 E

EN

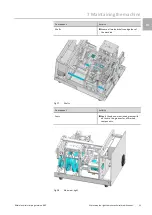

Fig. 13:

Counters

Key

1

Start: Microswitch

2

Drum position

3

Drum position

4

Drum position

5

Stop: Light barrier

6

Flap

7

Maintaining the machine

Warning!

Electrical shock caused by working on live components!

◼

Before working on the machine, it must be disconnected from

the power grid.

7.1

Authorised maintenance personnel

Maintenance work may be performed only by specially trained and instructed per-

sonnel.

7.2

Maintenance notes

Note:

–

Never clean the machine interior with compressed air.

–

Do not use spray oil or spray grease.

–

If possible, use silicone or PTFE oils (Teflon oil), e.g. Divinol GWA ISO

46.

–

Use lubricating greases suitable for roller bearings and sliding sur-

faces.

–

The display and the touch screen are made of plastic and must not

come into contact with hard objects. The touch-screen surface can

be cleaned with a soft cloth without any solvents.

7.3

Lubricant

Lubricating grease

–

Recommended grease: BP Energrease PR-EP 00

Lubricating oil

–

Recommended oil: WD-40 Classic

1

2

3

4

5

6