6

English

Contents

1. Application

2. Technical data

3. Assembly

4. Electrical connection

5. Commencing operation and control

behaviour

6. BUS System (Model No. SK 3124.000)

7. Technical information

8. Maintenance

9. Scope of supply and guarantee

10. Fault indication and fault analysis

11. Programming

1. Application

Enclosure cooling units are designed and built

to dissipate heat from enclosures, by cooling

the air inside the enclosure and protecting tem-

perature sensitive components. Enclosure cool-

ing units are particularly suitable for the

temperature range of + 40

°

C to + 55

°

C.

2. Technical Data

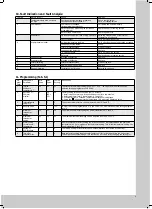

(see table 2.1)

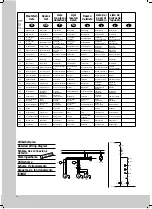

3. Assembly

The cooling unit can be mounted either inter-

nally, partially internally or externally.

Make cutouts and drill holes at the mounting

position (see fig. 3.1). Cut the enclosed seal to

the required length and attach it to the unit (see

fig. 3.2). In the case of external mounting screw

set-screws M8 x 30 into the blind nuts at the

rear face of the unit and fix them by means of

washers A 8.4 and nuts M8. In the case of parti-

ally internal mounting the unit has to be divided

by removing the lamella grille and unscrewing

the nuts M8. For external, partially internal and

internal mounting see fig. 3.2.

Prior to mounting, ensure that:

v

the site for the enclosure, and hence the

arrangement of the cooling unit, is selected

so as to ensure good ventilation;

v

the location is free from excessive dirt and

moisture;

v

the round cut-out for air extraction is located

in the upper area of the enclosure;

v

the mains connection ratings, as stated on

the name plate, are available;

v

the ambient temperature is no higher than

+ 55

°

C;

v

the packaging shows no signs of damage;

v

the enclosure is sealed on all sides.

Condensation will occur if the enclosure is

leaky;

v

the separation of the units from one another

and from the wall should not be less than

200 mm;

v

air inlet and outlet are not obstructed on the

inside of the enclosure;

v

units are only fitted vertically in the specified

position. Max. deviation from true vertical: 2

°

;

v

condensate discharge must be made up by

means of the material provided in the dis-

patch bag. The discharge tube must be free

from kinks and must be arranged sloping

away from the unit;

v

electrical connection and repair are carried

out only by authorized specialist personnel.

Use only original replacement parts!

v

To avoid an increase in condensation, a door

operated switch (e. g. PS 4127.000) should

be used which will switch the cooling unit off

when the enclosure door is opened (see

5.2.3.3).

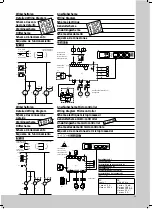

4. Electrical Connection

The connected voltage and frequency must corre-

spond to the values stated on the name plate. The

cooling unit must be connected to the mains via

an isolating device, which ensures at least 3 mm

contact opening when switched off. The unit must

not have any additional temperature control con-

nected before it. Line protection should be provid-

ed by means of the pre-fuse specified on the

name plate. Observe the relevant regulations

during installation!

Connect the mains connection to the plug-in ter-

minal strip X 10, see page 35.

Version . . . . .500 / .540

Door limit switch, see 5.2.3.3

v

Collective fault signal connection, see 5.2.3.1

v

Note the designations on the terminal strip (see

wiring diagram).

v

The unit must be disconnected prior to

checking the protective earth conductor, high

voltage and the insulation in the enclosure.

5. Commencing Operation

and Control Behaviour

Following the completion of mounting and a

waiting period of approximately 30 minutes (to

allow oil to collect in the compressor in order to

ensure lubrication and cooling) electrical connec-

tion can be made.

5.1 Control by Thermostat

Version . . . . .100 / .140

The cooling unit operates automatically, i.e. follow-

ing the electrical connection, the evaporator fan

will run continuously to circulate the air inside the

enclosure. This provides a uniform temperature

distribution in the enclosure. The built-in tempera-

ture controller (setting the desired internal tempe-

rature) effects automatically controlled switch-off

of the cooling unit by the value of the fixed

switching difference setting of 5 K. This is set at

the factory to + 35

°

C.

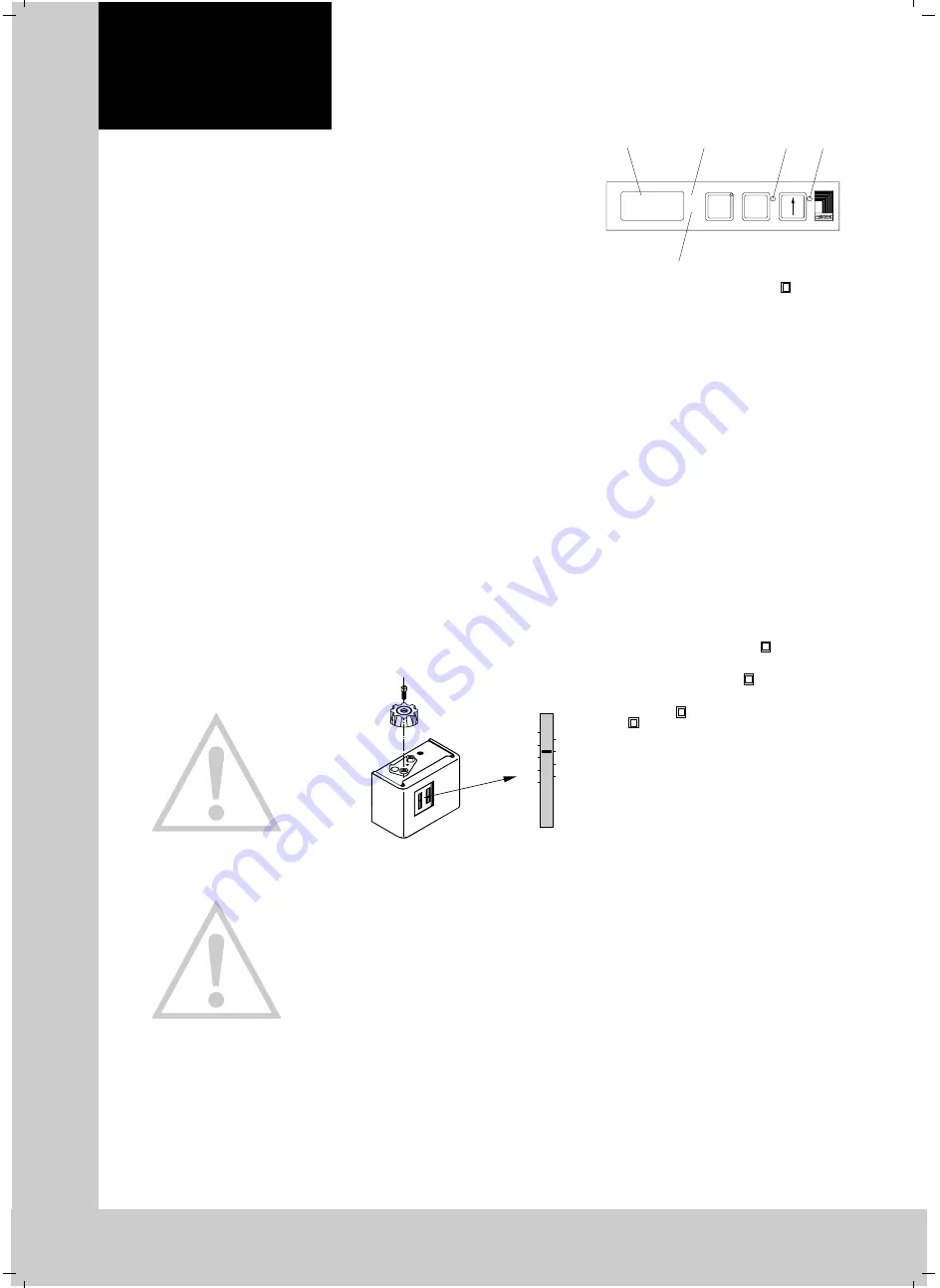

5.1.1 Temperature Setting at the Controller

Fig. 5.1

Thermostat

1. Remove the setting knob after slackening the

screw.

2. Remove locking plate.

3. Replace the setting knob and set the desired

temperature. Setting range + 20

°

C to + 55

°

C.

4. Replace the locking plate and fix the setting

knob by tightening the screw.

°C

10

20

30

8

6

4

3

°C

°C

55

60

50

45

40

35

25

5.2 Control by Microcontroller

Version . . . . .500 / .540

Fig. 5.2

Microcontroller

After electrical connection the internal fan turns on

and circulates the enclosure air. This helps assure

even temperature distribution within the enclosure.

The condensor fan and compressor are controlled

by the microcontroller. The minimum run time is

90 seconds. The switching difference is 5 – 10 K

and is set at the factory. In order to maximize

energy efficiency the thermostat should be set to

the highest enclosure temperature as allowed by

the electronics.

5.2.1 Operation of the Microcontroller

The display terminal H1 consists of a 3 position

7-segment display which indicates the enclosure

internal temperature in

°

C or

°

F (changeable, see

section 5.2.2) as well as any fault codes. The

actual enclosure internal temperature is con-

stantly displayed. If a fault occurs then the fault

number is indicated in the left position. When pro-

gramming the microcontroller the program level

and parameter value is indicated on the display.

When the “TEST” button is pushed the compres-

sor and the fans will run for 5 minutes regardless

of the internal temperature or door limit switch.

This allows for a system test after an extended

shutdown period (e.g. after the winter).

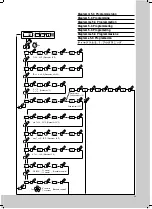

5.2.2 Programming

(see diagram 5.1 page 39)

In the EEPROM of the microcontroller various

parameters are stored which can be changed

through using the “ENTER” and “

” buttons,

9 different parameters are changeable as outlined

in table 5.1. To access the programming mode

push both the “ENTER” and “

” buttons simulta-

neously for 10 seconds. The left digit will then

indicate the program level and the LED for the

“ENTER” and “

” buttons will blink. By pushing

the “

” button the program level can be advan-

ced to the next level. In order to access levels

5 through 9 a security code must be entered. If no

buttons are pushed for 60 seconds the display will

return to the standard mode which displays the

enclosure temperature. Programming of the para-

meters is made easy with diagram 5.1 on page

39. A description of the parameters to be pro-

grammed can be found in table 5.1. All parame-

ters are stored in the EEPROM and are retained

when power is shut off to the air conditioner.

°C

TEST

ENTER

°F

H4

H5

H2

H1

H3

H1 = Display Terminal

H2 = LED

°

C

H3 = LED

°

F

H4 = LED ENTER

H5 = LED

➡

➡

➡

➡

➡