7

5.2.3 Fault Signalling Facility

All faults on the cooling unit are registered and

indicated by H1 as a fault number. The display is

by means of the left-hand number. The display

cycles through all pending fault messages in a

2 second cycle, starting with the internal tempera-

ture of the enclosure.

H1 indicates the following faults as a fault number.

1 = Enclosure internal temperature too high

(5 K above setpoint value)

2 = Current monitor, condenser

3 = Evaporator (no collective fault indication).

4 = High-pressure monitor

5 = Current monitor, condenser fan

6 = Current monitor, evaporator fan

7 = Filter mat soiled

8 = Temperature sensor cable break/short-circuit

5.2.3.1 Fault Signal Contact

(K1, potential-free)

The fault signal relay is pulled in at normal condi-

tion. Any faults will cause the relay to drop out

(except low-pressure monitor, fault number 3).

Any failure of the control voltage will also lead to

drop-out of the relay and can thus be registered.

The connection is made on the terminal strip X10.

For contact data and assignment, see wiring dia-

gram.

5.2.3.2 Filter Mat Monitoring

The specified filter mat has large pores and filters

coarse dust and lint from the air. Oil condensate is

partially separated out. Fine dust is drawn through

the filter mat and the external circuit of the unit

due to the high suction power of the fan. It does

not have any damaging effect on the function of

the unit.

Fig. 5.3

Filter Mat Replacement

Function of the Filter Mat Monitor:

The filter mat is monitored for soiling by meas-

uring the temperature difference in the external

circulation of the cooling unit. In the event of any

filter mat soiling, the temperature difference will

increase. The setpoint value of the temperature

difference in the external circulation is adapted to

various air conditioner operating conditions. This

eliminates the need for subsequent adjustment of

the setpoint value for different operating points of

the unit. (For the setting of the filter mat replace-

ment see table 5.1 and fig. 5.1).

5.2.3.3 Door Limit Switch S 2

(supplied by costumer)

Where a door limit switch is used and the enclo-

sure door is open (contact is closed when door is

open), the cooling unit (fans and condenser) will

switch off after approx. 10 s, thereby avoiding an

increase in condensation while the door is open.

To avoid cyclic operation, switch-on of condenser

and external fan is delayed by about 3 minutes

after the door has been closed. The internal fan

will start up immediately on closure of the door.

Connection is made at the terminal strip X10, ter-

minals 1 and 2. The extra low voltage is supplied

by the internal power pack, current is approx.

30 mA DC (no extra low safety voltage). Connect

the door limit switch free from potential only, no

external voltage! The display will flash during the

door delay time. The system message “1010” is

transmitted via the PLC interface.

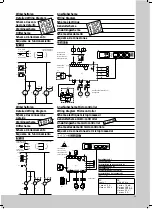

5.2.3.4 PLC Interface X2 (Option)

The interface is used for the transmission of the

actual internal temperature of the enclosure and

any system messages of the cooling unit to the

PLC. The transmitted information can be dis-

played by means of the output facilities (e.g.

plain text display) which are connected to the

PLC, or by means of the serial interface to a

higher order computer.

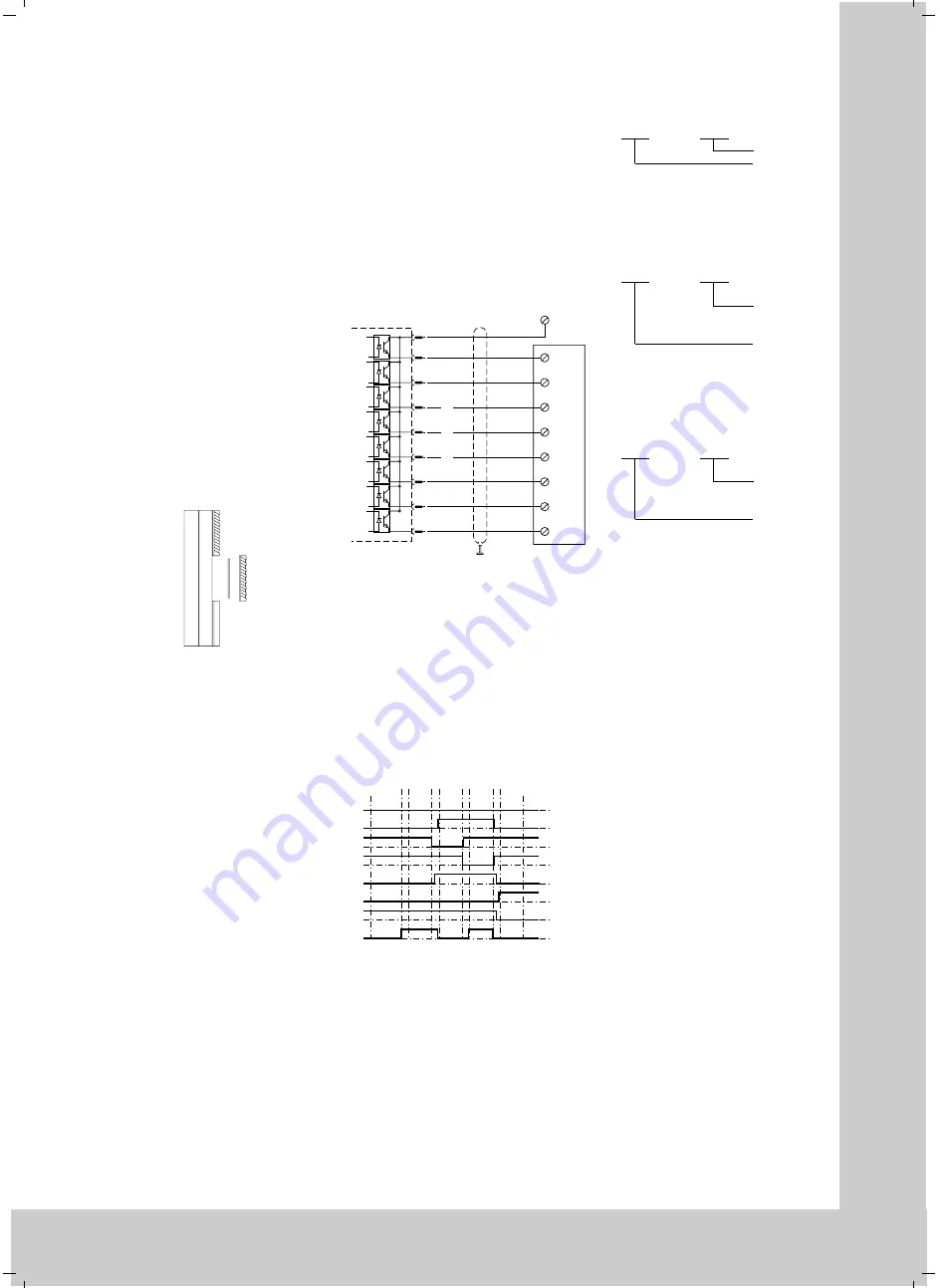

Construction of the PLC interface:

The construction is potential separated via opto-

coupler (wiring diagram fig. 5.4). Connection is

made by the customer to the 15-pin socket on the

control board (fig. 5.4) to the PLC input card.

Attention!

The electrical signals at the interface are of an

extra-low voltage (not extra-low safety voltages

according to EN 60 335).

Fig. 5.4

PLC Interface

Max. loading of the outputs:

30 V/10 mA, direct current

Connection: screened 15-core control cable

The possibility exists to access this information

over the PLC interface (level 8, table 5.1 or

fig. 5.1).

a) Standard mode (Level 8 = “0”)

Communication of the enclosure internal tempera-

ture and of the fault messages is made succes-

sively in 2 s cycle. Since this is an 8-bit parallel

transmission, input signals should not be accept-

ed as valid in the PLC until they have been pres-

ent for 0.5 s. This ensures that no invalid input in-

formation will be evaluated in the event of signal

changes at the inputs.

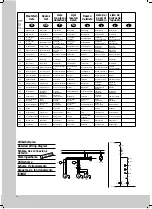

Fig. 5.5

PLC Interface X2

Pulse/time diagram (example)

9

1

E x.0

2

E x.1

e.g.

+ 24 V

3

E x.2

4

E x.3

5

E x.4

6

E x.5

7

E x.6

8

E x.7

PLC input card

Customer’s supply

15-pin. Sub-D

Cooling unit control card

2 sec.

2

7

6

5

4

3

2

1

0

8

7

6

5

4

3

2

1

0.5

2

0.5

2

0.5

2

0.5

X2

Sub-D plug

Pin

Temperature

32 °C 33 °C

5 Fault 6

store cancel

Temperature

34 °C

Bit

Enclosure internal temperature:

Transmission with 2 digits in BCD format:

System messages:

The system messages are transferred by means

of identification (4 bit) and a fault number

(1 digit BCD). The identification is structured as

follows:

In the event of a fault XXXX (BCD), the identifica-

tion is transmitted cyclically. This information

can be used to store the fault message in the

PLC.

This identification is transferred once, as soon

as the fault with the number XXXX/BCD has

been rectified. This information can be used to

delete the fault message in the PLC.

Evaluation of the interface signals in the PLC:

Messages:

If bit 1 and bit 3 of the input byte have a 1 signal,

the transmitted information is a system mes-

sage. In this case, the meaning of bit 0 is either

the information “store fault message” (bit 0 = 0)

or “cancel fault message” (bit 0 = 1).

Bit 4 to 7 represent the appropriate message

number (BCD).

Temperature:

If the AND operation of bit 1 and bit 3 is not fulfil-

led, the input information represents the actual

internal temperature of the enclosure. In this

case, both BCD digits have valid values (< = 9).

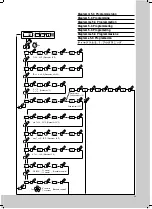

b) Parallel fault codes (Level 8 = “1”).

This can be accessed as follows:

Every one of the eight outputs stands for a cer-

tain system message (see below). It is not pos-

sible to display the internal temperature at the

same time as the system messages.

Output/

System Message

Bit

0

Max. enclosure internal temperature

1

Filter mat soiled

2

Enclosure door is open

3

High-pressure monitor

4

Evaporator

5

Current monitor, compressor

6

Current monitor, internal fan

7

Current monitor, external fan

Because these fault codes are transmitted

through an optocoupler, they can be switched to

a parallel transmission.

Bit 7

ZZZZ

EEEE

Units

Tens

0

Fault number

1 to 8

(see list)

Bit 7

XXXX

1010

Identification

0

“Store fault

message”

Fault number

1 to 8

(see list)

Bit 7

XXXX

1011

Identification

0

“Store fault

message”