Fig. 7.3

Condensate Discharge

7.4 General

Storage temperature: The cooling units must not

be subjected to temperatures above + 70

°

C

during storage. Transport attitude: The cooling

units must always be transported upright. Waste

disposal: The closed cooling circuit contains cool-

ant and oil which must be correctly disposed of

for the protection of the environment. The disposal

can be carried out at Rittal-Werk.

Technical modifications reserved.

8. Maintenance

As a maintenance-free, hermetically sealed

system, the cooling circuit has been filled in the

factory with the required amount of coolant, and

tested for leaks and subjected to a function trial

run. The installed maintenance-free fans use bull

bearings, they are protected against moisture and

dust, and are fitted with a temperature monitor.

The life expectancy is at least 30,000 operating

hours. The cooling unit is thus largely mainte-

nance-free.

All that may be required from time is that the com-

ponents of the external air circuit are cleaned by

compressed air. The use of a filter mat is recom-

mended only if large particles of lint are present in

the air, so that blockage of the condenser is pre-

vented.

(Filter mat replacement, fig 5.3)

Caution: Prior to any maintenance work, the

power to the cooling unit must be disconnected.

9. Scope of Supply

and Guarantee

1 cooling unit, ready for connection

8 setscrews M8 x 30

8 nuts M8

8 washers A 8.4

1 set of mounting and operating instructions

1 drilling template

1 sealing tape 10 x 8

1 sealing tape 10 x 4

4 (6) self-tapping screws B 4.8 x 13

4 (6) clamps

1 transparent hose 12 x 2 x 100

1 eyebolt (only with SK 3298. . . . /

3279.100 / 3260.500)

Guarantee:

This unit is covered by a 1-year guarantee from

the date of supply, subject to correct usage.

Within this period, the returned unit will be repair-

ed in the factory or replaced free of charge.

The cooling unit is to be used for the cooling of

enclosures only. If it is connected or handled

improperly the manufacturer’s guarantee does

not apply and in this case we are not liable for any

damage caused.

12 x 2 x 100

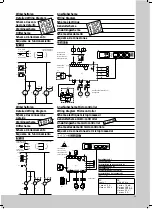

6. BUS System

(Model No. SK 3124.000)

6.1 General

The BUS system allows a maximum of 7 cooling

units to be interconnected. As a result, the follow-

ing functions are available to the operator:

v

Parallel unit control

(the cooling units in the network can be

simultaneously switched on and off).

v

Parallel door status messages (“door open”).

v

Collective fault message.

The data exchange is carried out using cables

(shielded two-wire leads).

All units are assigned an address. This address

also includes the ID for “Master” or “Slave”.

The BUS system cannot be used to link the

cooling units to a PC.

The PLC interface is switched to parallel error

encoding.

NOTE

The following restrictions must be heeded:

only 6 outputs (0 to 5) are available;

outputs 5, 6 and 7 are routed in parallel to

output 5.

6.2 Notes Regarding Installation

ATTENTION!

The electrical signals at the interface are of an

extra-low voltage (not extra-low safety voltages

according to EN 60 335).

Always heed the following notes!

v

De-energise the cooling units to be

connected.

v

Ensure proper electrical insulation.

v

Make sure the cables are not laid in parallel

to power lines.

v

Make sure that the lines are short.

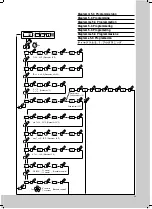

6.3 Programming the Cooling Unit

See diagram 5.1 for details on programming.

IDs:

NOTE

Only one unit may be configured as master;

the address ID must match the number of slave

units.

The individual slave units must have different

addresses; the addresses must be in ascending

order (without gaps in between).

Example:

1 master cooling unit with 2 slave cooling units

Master cooling unit

Slave cooling unit

00

Basic state

00

Basic state

01

Master

with 1 slave

11

Slave

with address 1

02

Master

with 2 slaves

12

Slave

with address 2

03

Master

with 3 slaves

13

Slave

with address 3

04

Master

with 4 slaves

14

Slave

with address 4

05

Master

with 5 slaves

15

Slave

with address 5

06

Master

with 6 slaves

16

Slave

with address 6

Master

02

Slave

11

Slave

12

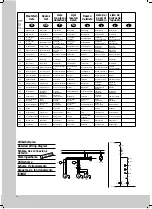

7. Technical Information

The cooling unit (compression refrigeration unit)

consists of four main components: the coolant

compressor, evaporator, condenser, and the con-

trol or expansion valve, which are connected by

suitable pipework. This circuit is filled with a

readily boiling substance, the coolant. The

R134 a (CH

2

FC

3

) coolant is free from chlorine. It

has an ozone destroying potential (ODP) of 0 and

is therefore environmentally friendly. A filter dryer

which is integrated in the hermetically sealed

cooling circuit, provides effective protection

against moisture, acid, dirt particles, and foreign

bodies within the cooling circuit.

7.1 Operation of the Cooling Unit

Fig. 7.1

Cooling Circuit

When a coolant compressor is put into operation,

the coolant vapour evaporates from the evapora-

tor. The heat required for the evaporation of the

coolant is drawn from the evaporator environment

(internal circuit of the enclosure), causing it to

cool down. The heat fed to the coolant in the

evaporator is its environment (assisted by fans),

making the coolant once more liquid due to the

condensation which takes place. In the thermo-

statically controlled expansion valve, the liquid

coolant is reduced to the particular evaporator

pressure required. The cooling which occurs due

to the reduction of pressure, releases the heat

from the liquid, which evaporates part of the cool-

ant flow. The mixture of cold liquid and throttle

vapour is returned to the evaporator. The cooling

cycle is thus completed, the aforementioned pro-

cess of the heat transfer starts afresh.

7.2 Safety Equipment

The cooling circuit of the cooling unit embodies

a component tested high-pressure monitor to

VBG 20.7.1 which is set to maximum operating

pressure and operates via an automatic reset

device at recurring pressure drop. Temperature

and low-pressure monitoring will prevent the eva-

porator from icing up. If there is a risk of icing up,

the condenser is switched off and automatically

switched on again at higher temperatures.

The coolant compressor and the fans are equip-

ped with thermal winding protection against

excess current and excess temperature.

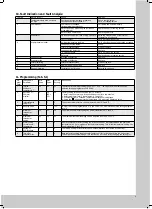

7.3 Condensate Discharge

Condensate which may form on the evaporator

(under high air humidity, low enclosure tempera-

tures) is discharged through a hose at the eva-

porator partition, at the bottom of the unit. A

connection through the condensate support piece

is used to make this selection (see fig. 7.3, take off

the louvred grille if necessary). Blockage of con-

densate must be avoided.

Fan 2

Fan 1

Pressostat

Compressor

Evaporator

External circuit

Internal circuit

Expansion valve

Thermostat

Filter

dryer

Liquefier

English

8