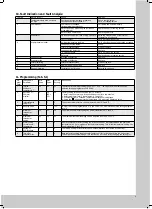

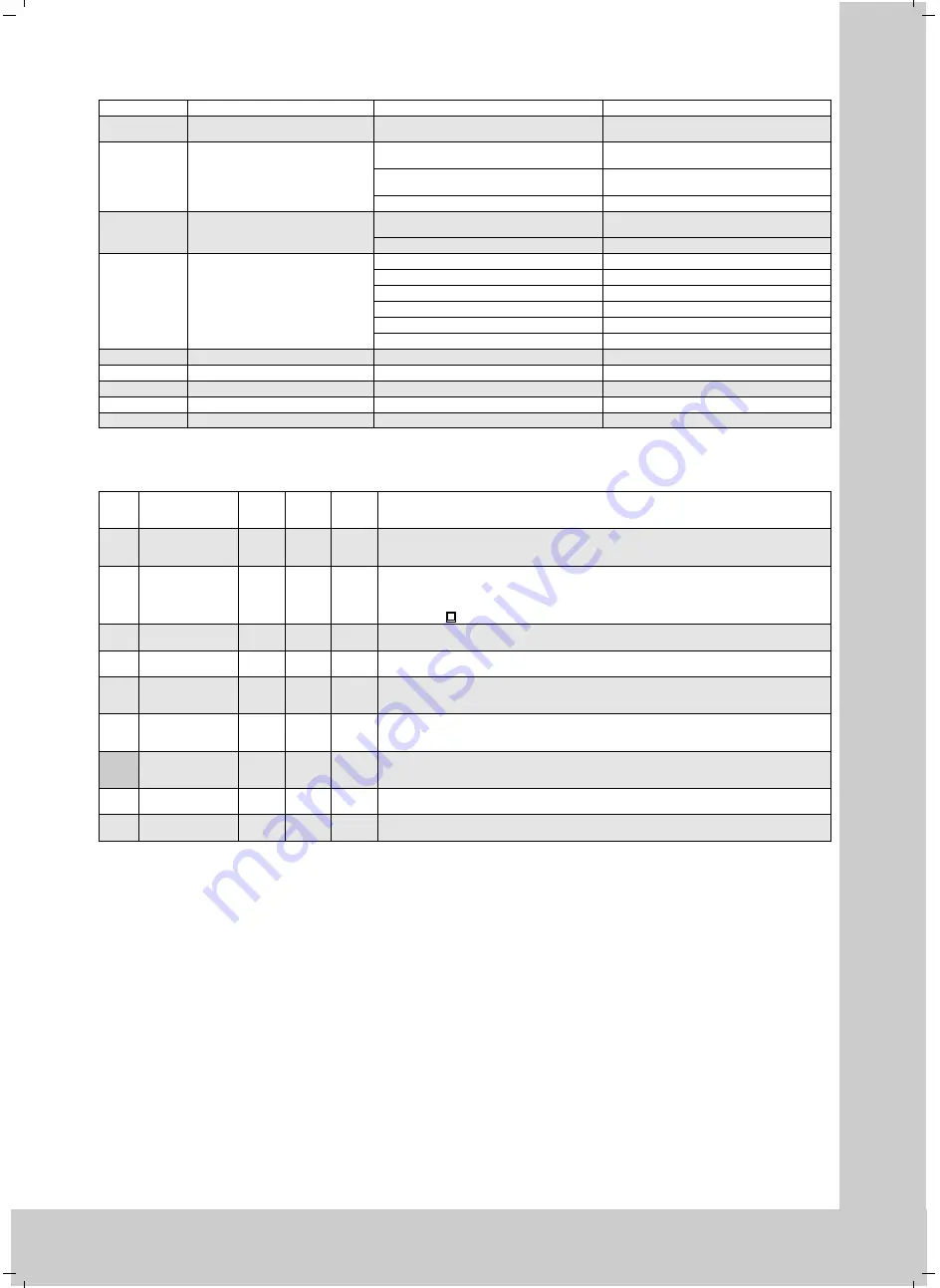

10. Fault Indication and Fault Analysis:

Fault No.

Nature of Fault

Cause

Remedy

1

Temperature inside the enclosure

too high

Cooling output too low (lack of coolant)

Consequential fault or faults 2 – 7

Check cooling output

Carry out cooling service

2

Compressor

Compressor overloaded

(internal winding protection)

Unit will switch on automatically

Defect (check by measuring the resistance

of the winding)

Replace as part of cooling service

Relay or feed cable faulty

Replace power PCB

3

Evaporator

Operational indication if risk of icing up exists

Raise the setpoint value of the internal

temperature of enclosure

Lack of coolant

Carry out of cooling service

4

High-pressure monitor

Ambient temperature too high

Unit’s specified range of application exceeded

Condenser contaminated

Clean

Filter mat contaminated

Clean or replace

Condenser fan defective

Replace

“E” valve defective

Carry out of cooling service

Defective

Replace as part of cooling service

5

Condenser fan

Blocked or defective

Replace

6

Evaporator fan

Blocked or defective

Replace

7

Filter monitoring

Filter mat contaminated

Clean or replace

8

Temperature sensor

Cable break or short-circuit

Replace

9

Phase monitoring

Incorrect field of rotation

Reverse two phases

9

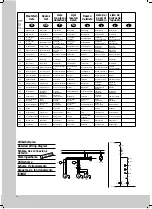

11. Programming (Tab. 5.1)

Pro-

gram

Level

Changeable

Parameter

Min.

Value

Max.

Value

Factory

Setting

Description

1

Internal

enclosure

temperature T

i

30

45

35

The standard thermostat setting range is 35 – 45

°

C. The upper and lower limits can be

adjusted through programm level 5 and 6.

2

Set value of

filter mat

monitor

4

40

(99 =

off)

99

Factory setting is the shut off value (99). To activate:

1. Install clean filter mat and let air conditioner cool for a few minutes.

2. Select programm level 2 (see diagram 5.1 page 39).

3. Push test button 10 seconds. Temperature difference is displayed.

4. Using the “

” button adjust the temperature 10 K above the displayed value.

3

Imperial/metric

units

°

C/

°

F

0

1

0

The enclosure temperature can be displayed in both

°

C and

°

F.

4

Security code

123

In order to access program levels 5 – 9 the code “123” must first be entered through program

level 4.

5

Minimum

thermostat

setting

20

35

30

The minimum thermostat setting can be adjusted from 35

°

C to 20

°

C.

6

Maximum

thermostat

setting

40

55

45

The maximum thermostat setting can be adjusted from 40

°

C to 55

°

C.

7

Alarm setting

for enclosure

temperature

3

15

5

Due to the standard factory setting of 5 K the fault code 1 is displayed when the enclosure

temperature is 5 K or more above the thermostat setting. This “alarm temperature” setting can

be adjusted from 3 to 15

°

C.

8

Setting of

PLC interface

0

1

0

The factory setting is for serial interface. Parallel interface is activated by selecting 1.

9

Turn off of

evaporator fan

0

1

0

With the factory setting the evaporator fan turns off for 1 minute each time the unit cycles.

This helps condensate drainage. This feature can be turned off by changing the setting to 1.

➡