34

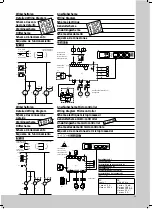

Anschlußschema

Microcontroller

A1

= Leistungsplatine

A2

= Anzeigeterminal

B1

= Temperaturfühler Innentemperatur

B2

= Temperaturfühler Vereisungsschutz

B3

= Temperaturfühler außen 1

B4

= Temperaturfühler außen 2

C1-C4 = Betriebskondensatoren

F1

= Thermostat

F2

= Pressostat

K1

= Relais Sammelstörung

M1

= Verdichter

M2

= Verflüssigerventilator

M3

= Verflüssigerventilator

M4

= Verdampferventilator

S2

= Türendschalter (ohne Türendschalter

Klemme 1, 2 offen)

T1

= Transformator

Kundenseitiger Anschluß:

X2

= SPS-Schnittstelle

(Sub-D-Buchse 15pol.)

X10

= Anschlußklemmleiste

X10

= L1, L2/N, PE = Netzanschluß

braun = L1 (Phase)

blau = L2/N (Neutral)

grün/gelb = PE (Erdung)

L1, L2, L3 (SK 3260.500)

X10

= 1, 2 = Türendschalteranschluß

(Kundenbeistellung)

X10

= 3, 4, 5 = Sammelstörmeldung

Aansluitschema

mikro-controller

A1

= Hoofdstroomprint

A2

= Display

B1

= Temperatuursensor interne temp.

B2

= Temperatuursensor ijsvorming

B3

= Temperatuursensor buiten 1

B4

= Temperatuursensor buiten 2

C1-C4 = Motorkondensator

F1

= Termostaat

F2

= Pressostaat

K1

= Relais verzamelstoring

M1

= Kompressor

M2

= Kondensorventilator

M3

= Kondensorventilator

M4

= Verdamperventilator

S2

= Deurschakelaar (zonder deur-

schakelaar klem 1, 2 open)

T1

= Transformator

Elektrische aansluiting door klant:

X2

= PLC-interface

(Sub-D-konnektor 15-polig)

X10

= Klemmenstrook

X10

= L1, L2/N, PE = netaansluiting

bruin = L1 (Fase)

blauw = L2/N (Nul)

groen/geel = PE (Aarde)

L1, L2, L3 (SK 3260.500)

X10

= 1, 2 = aansluiting deurschalkelaar

(door klant te installeren)

X10

= 3, 4, 5 = algemene storingsindikatie

Esquema de conexiones

del microprocesador

A1

= Pletina de potencia

A2

= Pantalla indicadora

B1

= Sonda térmica de la temp. en el

interiore del armario

B2

= Sonda térmica protección

contra congelación

B3

= Sonda térmica exterior 1

B4

= Sonda térmica exterior 2

C1-C4 = Condensador electrolitico de servicio

F1

= Termostato

F2

= Presostato

K1

= Relé de fallo

M1

= Compresor

M2

= Ventilador del condensador

M3

= Ventilador del condensador

M4

= Ventilador del evaporador

S2

= Interruptor de puerta (sin interruptor

final borne 1, 2 abierto)

T1

= Transformador

Connexión por parte del cliente:

X2

= Interfase de la LCP

(base casquillo D-sub 15 pol.)

X10

= Regleta de bornes

X10

= L1, L2/N, PE = Conexión de red

L1, L2, L3 (SK 3260.500)

X10

= 1, 2 = Bornes de conexión del

interruptor final de carrera S 2,

cierre puerta

X10

= 3, 4, 5 = Bornes de conexión

(señal averia)

D

NL

E

Wiring Diagram

Microcontroller

A1

= Power PCB

A2

= Display Terminal

B1

= Temperature sensor, internal temp.

B2

= Temperature sensor, risk of icing

B3

= Temperature sensor, external 1

B4

= Temperature sensor, external 2

C1-C4 = Operating capacitors

F1

= Thermostat

F2

= Pressostat

K1

= Relay collective fault

M1

= Compressor

M2

= Condenser fan

M3

= Condenser fan

M4

= Evaporator fan

S2

= Door limit switch (without door operated

switch terminal 1, 2 open)

T1

= Transformer

Electrical Connection by Customer:

X2

= PLC interface

(Sub-D-socket, 15-pole)

X10

= Terminal strip

X10

= L1, L2/N, PE = Mains connection

brown = L1 (phase)

blue = L2/N (neutral)

green/yellow = PE (ground)

L1, L2, L3 (SK 3260.500)

X10

= 1, 2 = Door operated switch

connection (supplied by customer)

X10

= 3, 4, 5 = Collective fault message

Anslutningsschema

microcontroller

A1

= Drivkort

A2

= Display terminal

B1

= Temperaturgivare innertemperatur

B2

= Temperaturgivare nedisningsrisk

B3

= Temperaturgivare yttre 1

B4

= Temperaturgivare yttre 2

C1-C4 = Startkondensator

F1

= Termostat

F2

= Pressostat

K1

= Samlingsrelä felsignaler

M1

= Kompressor

M2

= Kondensorfläkt

M3

= Kondensorfläkt

M4

= Förångarfläkt

S2

= Dörrströmbrytare (utan dörrström-

brytarklämma 1, 2 öppna)

T1

= Transformator

Ansluts av kund:

X2

= PLC-ingång

(D-Sub-uttrag 15-pol)

X10

= kopplingsplint

X10

= L1, L2/N, PE = nätanslutning

brun = L1 (Fas)

blå = L2/N (Nolla)

grön/gul = PE (Jord)

L1, L2, L3 (SK 3260.500)

X10

1, 2 = anslutning dörrkontakt

(måste beställas separat)

X10

= 3, 4, 5 = samlingsstörnings-anslutning

GB

S

J

Schéma électrique

microprocesseur

A1

= Platine de puissance

A2

= Display Terminal

B1

= Sonde te température,

température intérieure

B2

= Temp. sensor danger de givrage

B3

= Sonde de température extérieure 1

B4

= Sonde de température extérieure 2

C1-C4 = Condensateur de régime

F1

= Régulateur de température

F2

= Pressostat

K1

= Relais pertubations

M1

= Compresseur

M2

= Ventilateur du condenseur

M3

= Ventilateur du condenseur

M4

= Ventilateur de l’évaporateur

S2

= Interrupteur de porte (sans contacteur

les bornes 1, 2 sont ouverttes)

T1

= Transformer

Electrical Connection by Customer:

X2

= Interface SPS

(douille Sub-D 15 pôles)

X10

= Borne plate de raccordement

X10

= L1, L2/N, PE = Raccordement au résau

brun = L1 (phase)

bleu = L2/N (neutre)

vert/jaune = PE (mise à la terre)

L1, L2, L3 (SK 3260.500)

X10

= 1, 2 = Raccordement de l’interrupteur

de porte (à monter par le client)

X10

= 3, 4, 5 = Connexion de la signalisation

de défaut

Schema allacciamenti

microcontrollore

A1

= Scheda di potenza

A2

= Display terminale

B1

= Sonda temperatura interna

B2

= Sonda temperatura,

pericolo di formazione di ghiaccio

B3

= Sonda temperature esterna 1

B4

= Sonda temperature esterna 2

C1-C4 = Condensatore d’esercizio

F1

= Termostato

F2

= Pressostato

K1

= Relè segnalatore guasti

M1

= Compressore

M2

= Ventilatore del condensatore

M3

= Ventilatore del condensatore

M4

= Ventilatore dell’evaporatore

S2

= Interruttore della portina (senza inter-

ruttore i morsetti 1, 2 sono aperti)

T1

= Transformatore

Connessioni elettriche a cure del cliente:

X2

= Interfaccia PLC

(presa 15 poli)

X10

= Morsettiera d’allacciamento

X10

= L1, L2/N, PE = Allacciamento rete

marrone = L1 (fase)

azzurro = L2/N (neutro)

verde/giallo = PE (terra)

L1, L2, L3 (SK 3260.500)

X10

= 1, 2 = Allacciamento interruttore fine

corsa della portina (forn. dal cliente)

X10

= 3, 4, 5 = Segnalatore comune disturbi

F

I