2

5

4

3

2

1

L1

B3

B2

B1

PE

21

22

B4

2

2

2

6

8

TEST

ENTER

°F

°C

15

Technische Daten

siehe Typenschild

L2 L3

4

5

gg

1

2

3

1 2 3

5

4

6

6

4 5

3

2

1

1 2 3

5

4

6

1

2

K1

X10

A1

S2

A2

X2

F2

L3

L2

L1

F10

M1

F20

M2

M4

F40

SK 3260.500

V

W

U

3

M

M

3

P

Technical data

see name plate

SK 3290.500 without/ohne C3

SK 3290.500 without/ohne C3

M2

K1

SK 3293.500

SK 3298.500

SK 3298.500

A1

S2

C2

C4

M4

M3

C2

C1

M2

SK 3293.500 without/ohne C1

SK 3298.500

SK 3298.500

A2

X2

M1

F2

2

5

4

3

2

1

L1

PE

21

22

B3

B2

B1

B4

2

2

2

6

8

°C

TEST

ENTER

°F

15

14

11

10

13

12

L1

PE

L2

N

2

1

3

5

4

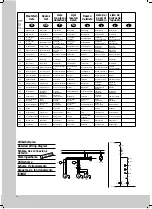

Technical data

see name plate

Technische Daten

siehe Typenschild

P

M

1~

1~

M

M

1~

1~

M

L2

N

X10

M

1~

M

1~

M

1~

L/L'

N

L

N

ϑ

>

P>

N

PE

L

Technische Daten

siehe Typenschild

* nur bei Trafoeinbau

P<

L'

*

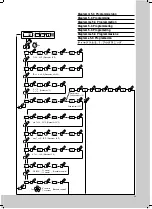

F2

M1

M2

M4

C1

F1

C4

F3

C2

T1

Techn. data

see type-plate

F2

M1

C1

F1

C4

L/L'

N

L

N

F3

C2

N

PE

L

L'

T1

M

M2

1~

M4

M

1~

M

1~

F3

F3

ϑ

>

P>

s. Typenschild

Techn. Daten

* nur bei Trafoeinbau,

*

only for transformer

*

see type-plate

Techn. data

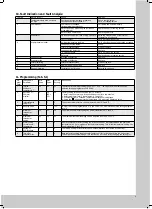

Kontaktdaten K1

Contact Data K1

Caracteristiques des contacts K1

Kontaktgegevens K1

Kontaktdata K1

Caratteristiche dei contatti K1

Características del contacto K1

AC

cosf = 1

DC

L/R = 40 ms

I max.= 5 A

U max.= 230 V

I min. = 10 mA

U max.

= 100 V

!

I max.= 200 mA

U max.= 20 V

!

I max.= 5 A

K 1

35

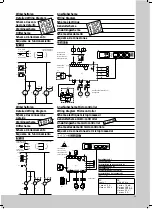

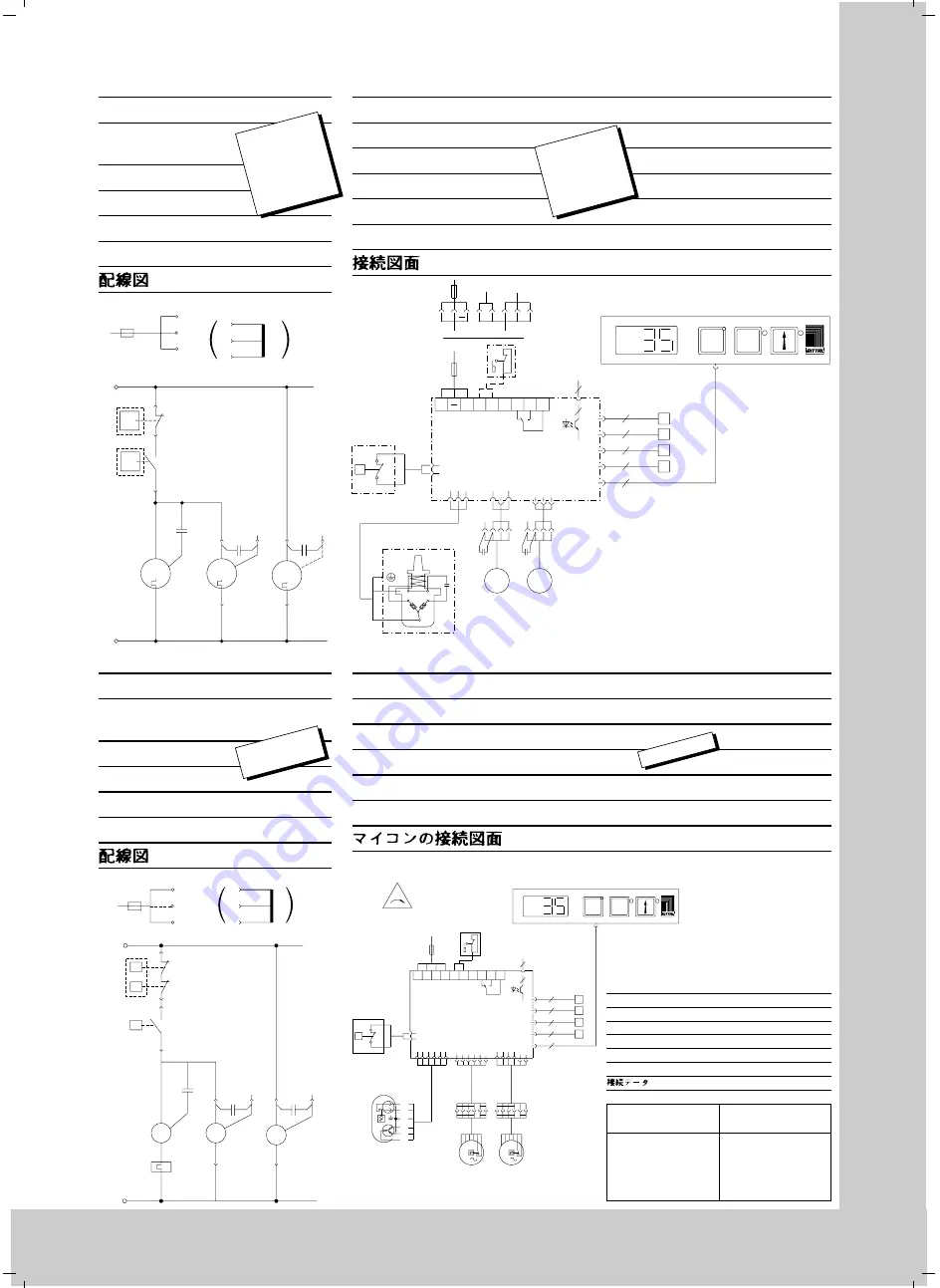

Wirkschaltplan

Detailed Wiring Diagram

Schéma des con-

nexions détaillé

Werkingsschema

Driftschema

Schema d’allacciamento

Esquema de funcionamiento

Anschlußschema

Wiring Diagram

Schéma électrique

Aansluitschema

Anslutningsschema

Schema allacciamenti

Esquema de conexiones

Wirkschaltplan

Detailed Wiring Diagram

Schéma des connexions

détaillé

Werkingsschema

Driftschema

Schema d’allacciamento

Esquema de funcionamiento

SK 3293.100

SK 3293.140

SK 3281.100

SK 3393.100

SK 3393.140

SK 3381.100

SK 3298.100

SK 3279.100

Anschlußschema Microcontroller

Wiring Diagram Microcontroller

Schéma électrique microprocesseur

Aansluitschema mikro-controller

Anslutningsschema microcontroller

Schema allacciamenti microcontrollore

Esquema de conexiones del microprocesador

SK 3260.500

SK 3293.500

SK 3293.540

SK 3393.500

SK 3393.540

SK 3398.500