9

EN

Date: 01-05-2015

Installation Guide

33130328

Description

Technical specifications

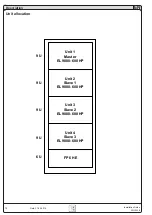

Type: Rittal TS8 42U

Dim (WxHxD): 600 mm x approx. 2000 mm x 800 mm

Model: rear and front doors, on wheels

AC input connection: L+N+PE

AC input voltage: 115/230 V AC

Ambient temperature: 5....40 °C

Humidity: <80%, non-condensing

Weight: ~390 kg

DC input: 80 V / 2400 A / 21600 W

Feature overview

• Wheels (4 pcs. of which 2 can be locked)

• Equipped with 4x EL 9080-600 HP of 9U height each

• Master-Slave wiring on analog interfaces

Installation

Cabinet

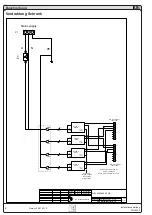

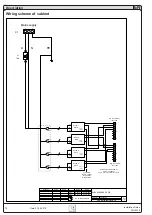

The AC input connection is done using screw terminals which

are accessible on the rear side in the bottom right corner and

labelled L1, N, PE. The input is fused with a 16A circuit breaker

(F1), so the cross section of the AC supply cables has to be

selected accordingly.

For additional safety, every unit has a fusible, which is accessible

on the rear of the units in a fuse holder and labelled with the fuse

value (see sticker).

Units

The electronic load units are delivered separately and have to be

inserted after the cabinet has been installed in the target location.

The devices are of same model, so they can be placed anywhere.

After inserting and mounting the units, you need to connect:

• AC supply (IEC cable)

• DC input (cables, red/blue, 4 cable ends per units)

• Master-slave wiring on analog interface, if required

DC input

The four units are connected in parallel via cables on two copper

bars for DC plus and DC minus. The DC terminal is not protected

against physical contact.

The DC input copper bars for voltage/current source connection

are down below on the rear and are horizontally mounted.

DC source are connected via cables (or similar) with proper cross

section (according to local standards) on the DC input copper

bars, using M12 nuts and bolts.

Attention!

Always connect only DC sources and only with cor-

rect polarity!

The electronic loads do not have protection against

false polarity and can even be damaged in switched-

off state.

Analog interface

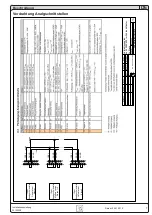

The analog interface of all units in the cabinet can be used

with the preconfigured wiring to have a current driven mas

-

ter-slave system. The topmost unit is defined as master

unit. All units are labelled on the front side.

The slave units are in permanent remote control (indicated

as „External mode“ in display) as long as the master-slave

wiring on the analog interface is plugged. In case you need

to access a unit separately or take over remote control via

digital interface, it is sufficient to remove the plug from the

analog interface.

When re-configuring the cabinet or in case of removing an

unit for repair, the setup of master and slave units should be

kept and the master-slave wiring re-connected as before.

Operation

Handling of the electronic loads

See separate manual of EL 9000 HP 7200W.

General

For general information about remote control of the electronic

loads via analog or digital interface refer to various available docu-

mentation (device manual, interface manual, programming guide).

Remote control

Note

It is generally possible to remotely control all units at once

or just single units.

With the given situation, remote control is only intended for

the master unit, because it controls the slave units. These can

only be monitored via digital interface, unless master-slave is

disconnected.

The software Easyload Lite, as supplied from the manufacturer

of the electronic loads, is designed to control only one unit. This

should be the master unit. In case all four units of a cabinet are

networked, the software will detect four identical units and the

particular master can only be distinguished from the slaves by its

IP or the serial number. Thus Easyload Lite is only of limited use.

In order to control the whole cabinet as one big system, it requires

to create a custom software, which either controls only the master

unit and translates all values accordingly before sending it to

the device. Because of the analog master-slave wiring, there is

no digital communication between the units and so the master

unit has to be considered as single device concerning values to

send/receive.

Alternatively and at least when monitoring the units regarding

set values, the single units could be read and totalled, so the

resulting actuals are more accurate than just reading the master

and multiplying current and power by the number of units.