Instruction Manual IM‐116

CUSTOMER'S INFORMATION BOX

CONTENTS ARE INDEPENDENT OF RIVERHAWK DOCUMENT CONTROL

215 Clinton Road

New Hartford, NY 13413

Tel: +1 315 768 4855

Fax: +1 315 768 4941

Email: info@riverhawk.com

REV

373A4028

GE DRAWING NUMBER

Revision H

Page 11 of 29

Puller screw should be free to rotate and move back and forth.

Seam between cylinders closed tightly.

Inspect tensioner guard for any signs of damage. Bent guards should be replaced. Also, be sure

the rubber pad is in place on the end of the guard, if missing, replace.

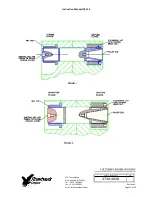

7.1.1 Fittings

Make sure both male and female parts are clean and free of debris, see Figure 3 for fitting

configuration. Hold female part securely when tightening so as to prevent damage to adjacent

tubing. If fitting leaks first try retightening as needed. If leaking continues then disassemble

and check for scratches or debris on the seating conical surfaces. Clean as required. Replace

plastic caps when finished with tooling.

7.2 Pump

The pump kit is shipped full of hydraulic oil. The pump reservoir cap is sealed for shipment. To

use turn cap to the vent position. To prevent oil spillage close cap when not in use, during

storage and shipment. Lost oil should be replaced with Enerpac Hydraulic Oil. ISO 32. Mineral

Oil may be substituted, if necessary.

7.3 Bleeding Hydraulic System

Follow the tensioner assembly instructions of Section 8.0.

TO AVOID FAILURE, ENSURE SAFETY AND PROPER OPERATION THE TENSIONER ASSEMBLY

MUST BE MOUNTED ON THE STUD BEFORE BLEEDING THE SYSTEM AND TENSIONING BEGINS.

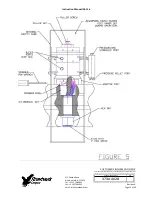

The tensioner has four ports see Fig. 5, one for pressurizing, two for bleeding the system and a

fourth pressure relief port.

To facilitate bleeding, start by first mounting the tensioner at either the 3 0’clock or 9 o’clock

stud position depending on which will critically place the bleed ports in their uppermost

position. In addition, make sure that the pump is always situated below the tensioner assembly.

The puller tool is equipped with 5/8 in. [16 mm] Hex coned stem bleeder fittings installed in the

bleeder ports. With theses two fittings loosened simultaneously, stroke the pump repeatedly

until the streams of oil exiting the tool from each port are free of air, then retighten the fittings.