Instruction Manual IM‐116

CUSTOMER'S INFORMATION BOX

CONTENTS ARE INDEPENDENT OF RIVERHAWK DOCUMENT CONTROL

215 Clinton Road

New Hartford, NY 13413

Tel: +1 315 768 4855

Fax: +1 315 768 4941

Email: info@riverhawk.com

REV

373A4028

GE DRAWING NUMBER

Revision H

Page 13 of 29

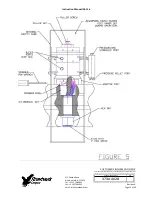

If the puller tool is not free to rotate when the puller screw is tight, then either. (1) The

tensioner is damaged, or. (2) The stud is not properly positioned in the flange and the nuts

must repositioned. This can be done as follows.

1.

Slightly loosen the puller screw

2.

Back the nut opposite the puller tool off about 1/2 turn

3.

Tighten the puller screw side nut to take up the slack.

4.

Retighten the puller screw per above and check for looseness of tool

CAUTION

Personal injury and equipment damage can occur if the puller screw is not securely engaged

with the tapered thread of the stud. Proper engagement is achieved when the puller screw is

tight in the stud and the Tensioner Assembly is free to rotate.

9.0 Stud Pulling and Tensioning

The studs will be tensioned in two steps, at approximately 50% pressure and at final pressure.

Follow the tensioning sequence for each flange joint as defined on the data sheets found at the

end of this manual

Note:

Before threading the puller screw into the stud, carefully check the cleanliness of both

the stud's and the puller screw's conical threads. Apply a light coat of clean turbine oil or a

spray lubricant to the puller screw. Do not use “Never Seize” on the conical threads. This

procedure will ease assembly and assure positive mating of the threads before tightening.

WARNING

The safety cage MUST be in place and hands kept out of designated areas at all times when the

puller tool is pressurized otherwise personal injury can occur.

9.1 Tensioning at 50% pressure

After the tensioner is properly installed apply hydraulic pressure to the tool. Bring the pressure

to the 50% level in accordance with the following table.