11

34-55 08/14

5.7 Gas Control Trains

All models include gas control trains with the following components: main gas cock, a dual safety valve,

proportionator regulator and a final manual shutoff valve with the manifold pressure tap on the side of the valve.

CAUTION

: Do not adjust or remove any screws or bolts on gas train control components which are sealed with a red

or blue colored compound. Doing so will void all approvals and warranties.

6

COMBUSTION AND VENTILATION AIR

Provisions for adequate combustion and ventilation air to the mechanical room must be in accordance with Section

5.3, Air for Combustion and Ventilation of the latest edition of the National Fuel Gas Code, ANSI Z223.1 and/or

CAN/CSA B149, Installation Codes or applicable provisions of the local building codes.

6.1 Equipment Located In Confined Spaces

Equipment located in confined spaces requires two openings installed within 12” (30.5 cm) from the top and bottom

of the room to assure adequate combustion air and proper ventilation. The total input of all gas utilization equipment

installed in the room must be used to determine the required minimum air volume needed for combustion, ventilation

and dilution of flue gasses.

•

All Air From Outdoors:

Each opening requires a minimum free area of 1 square inch

per 4000 Btu/hr input if directly communicating

with the outdoors or communicating to the outdoors through vertical ducts.

Each opening requires a minimum free area of 1 square inch

per 2000 Btu/hr input if communicating with the

outdoors through horizontal ducts.

•

All Air From Inside The Building:

Each opening requires a minimum free area of 1 square inch

per 1000 Btu/hr input, but not less than 100 square

inches (0.06 m

2)

.

•

Combination Of Air From The Indoors And From The Outdoors:

Refer to National Fuel Gas Code, ANSI Z223.1 and/or CAN/CSA B149, Installation Codes or applicable

provisions of the local building codes.

NOTE

: This unit may be installed with a remote air intake system which uses a make-up air duct to draw combustion

air directly from outdoors. (See Vertical and Horizontal Remote Air.)

WARNING – Adequate clean combustion air must be provided to the appliance. Under no circumstances

should the appliance ever be under a negative pressure. Particular care should be taken when exhaust fans,

compressors, air handling units, etc. may rob air from the appliance. The combustion air supply must be

completely free of any chemical or fumes, which may be corrosive to the appliance. Some common chemical

fumes to avoid are fluorocarbons and other halogenated compounds, most commonly present as

refrigerants or solvents, such as Freon, trichloroethylene, perchlorethylene, chlorine, etc. These chemicals,

when in contact with the equipment or when burned, form acids which quickly attack the tubes, flue

collector, stack and other appliance and auxiliary equipment. The result of inadequate clean combustion air

or negative pressure can be premature unwarranted product failure or unsafe operation producing carbon

monoxide that could escape into the building. Exposure to carbon monoxide can lead to personal injury or

death.

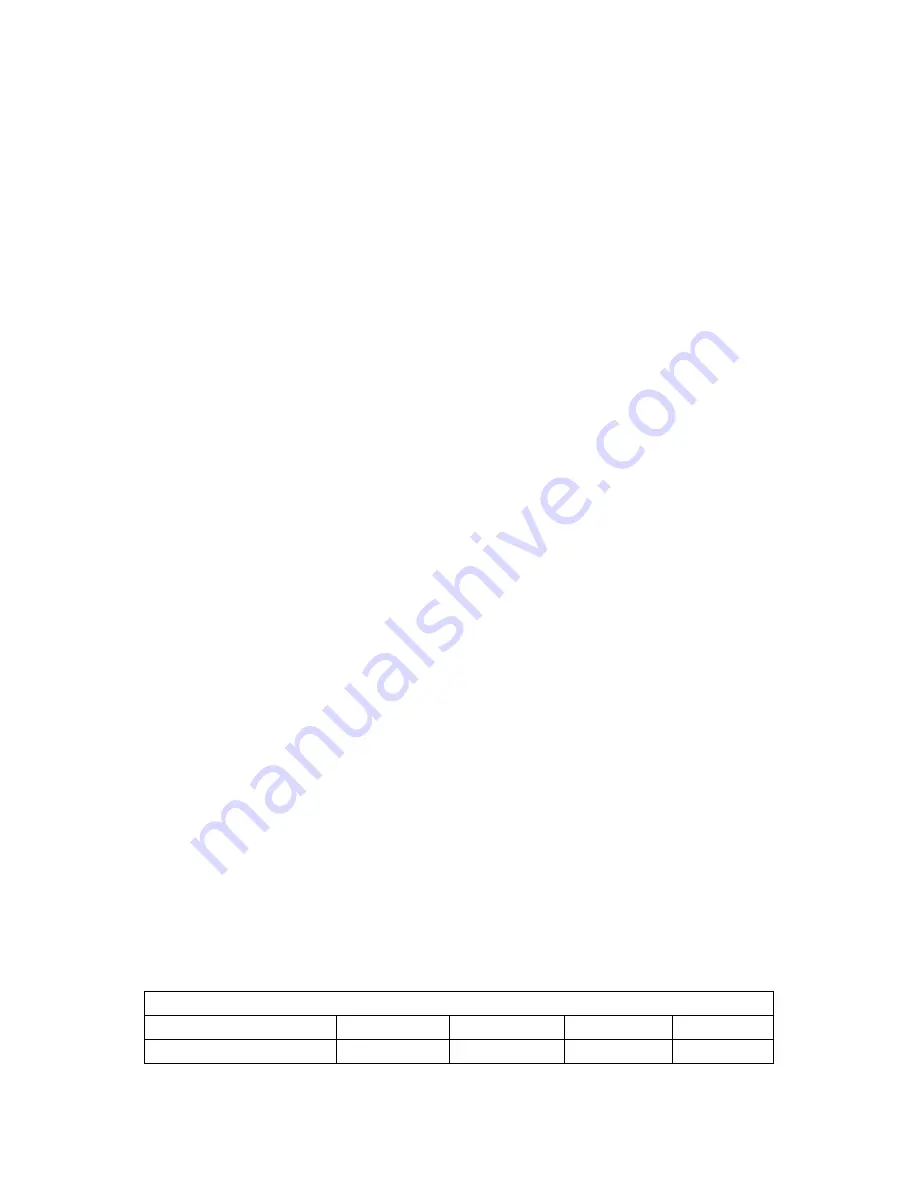

6.2 Maximum Allowed Remote Combustion Air Inlet Length (Equivalent Length)

A vertical or horizontal remote air inlet system can be connected to this appliance without modification.

The

maximum length of field supplied single wall pipe, such as galvanized ventilation pipe, is shown in the chart below

titled Maximum Air Inlet Duct Equivalent Length. Use metal tape or RTV sealant to seal each pipe joint.

Maximum Air Inlet Duct Equivalent Length

Duct Size

6” Duct

7” Duct

8” Duct

9” Duct

Max Equivalent Length

100 feet

130 feet

250 feet

450 feet

To determine the maximum straight length of duct allowed, use the Duct Fitting Equivalent Length chart below to find

the total equivalent length for all duct fittings in your combustion air system. Then subtract this number of feet from